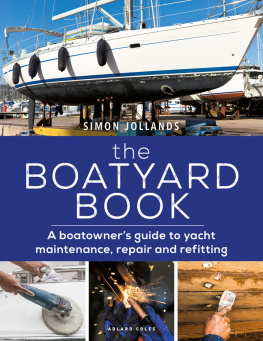

CONTENTS

INTRODUCTION:

BEAUTY IS MORE THAN SKIN DEEP

Fiberglass.

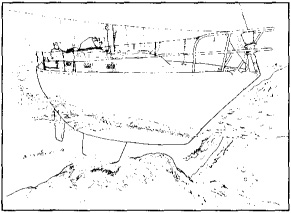

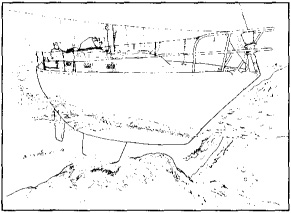

Legendary yacht designer L. Francis Herreshoff hassomewhat inelegantly, it seems to me called this versatile material frozen snot. Maybe so, but how many of Herreshoffs beautiful wooden boats have ended up as lobster condominiums or fuel for a boat shed stove, while snot-built boats of the same age, no matter how undeserving of immortality, continue to ply the worlds oceans, bays, and estuaries? Wooden boats regularly die early deaths of natural causes; fiberglass boats must be assassinated.

Dont get me wrong; I love wooden boats, and in particular I love Herreshoffs wooden boats. There is something magical about taking straight lumber and manipulating it into the flowing contours of a boat. The craftsmanship of the builder is obvious: planks steamed to linguini and worried into compound curves, knees cut from a natural crook to harness the trees full strength, precise dovetail joints wedding shelf and beam. Such craft is far less evident in a hull formed by painting a boat-shaped mold with a thick layer of fiber and sticky glop. That the dried glop pops out of the mold with the same graceful curves yields no redemption.

But it isnt redemption that is called for; its perspective. If we open the leaded glass doors in the galley of one of Mr. Herreshoffs classic wooden yachts, we are likely to encounter fine china. Why not wooden plates, woven bowls? Because china dishesmolded bone-reinforced clayare infinitely more serviceable.

Likewise molded glass-reinforced plastic boats.

Fiberglass is malleable, durable, and easy to maintain. These characteristics, widely known, have made fiberglass the overwhelming material of choice for boat construction for more than three decades. If you want a boat to display, wood has much to recommend it, but for a boat to use, fiberglass is hard to beat.

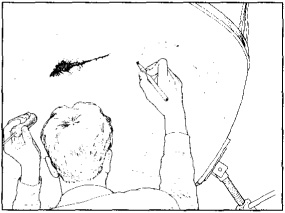

A lesser-known virtue of fiberglass is that it is easy to repair. A fiberglass hulls seamless nature leads many boatowners to conclude that repair must be difficult. Any assertion to the contrary too often elicits raised eyebrows. In the pages that follow, we hope to quell the skeptics with astoundingly clear explanations, but the only way you can fully purge yourself of any nagging doubts is to buy a can of gelcoat paste or a bit of glass cloth and resin and give it a whirl. Youll wonder what you were worried about.

While this book is confined to hull and deck repairs to fiberglass boats, it is not limited to fiberglass repairs. Fiberglass boats are not all fiberglass. Decks, for example, may be cored with plywood, balsa, or foam, railed with aluminum, covered with teak, outfitted with bronze, interrupted with acrylic, penetrated with stainless steel, and booted with rubber. Virtually all of these components require regular maintenance and occasional repair, and they must be assembled properly and carefully if the boat is to be dry.

Watertight joints are our first order of business. Boatowners today dont need even a passing acquaintance with oakum caulking and firming irons; molded hulls are completely seamless, and rare is the fiberglass hull that leaks, no matter how old. Deck leaks are, unfortunately, another matter. The dirty little secret of fiberglass boats is that most are only slightly more watertight than a colander. Spray? Rain? Wash-down water? A significant amount of all three finds its way below.

Deck leaks dont just wet the contents of lockers, drip on bunks, and trickle across soles; they destroy wood core, corrode chainplates, and delaminate bulkheads. Identifying and eliminating leaks is essential. This book details the most effective technique for sealing joints and bedding hardware, and it provides specific sealant recommendations for various uses. It instructs you in portlight replacement, hull-to-deck joints, and centerboard trunk repairs. It also shows you how to test your work and how to locate pesky leaks.

Often all that is wrong with a fiberglass hull is a chalky surface or a few scratches. Restoring the gloss can be the easiest of repairs to fiberglass; it is where we begin our exposition of this material.

The ravages of time affect decks more than hulls. An older fiberglass deck is likely to be webbed with hairline cracks, even pocked with open voids, and may have stress cracks radiating from corners or from beneath hardware. Fortunately there are easy ways to repair these blemishes. Step-by-step instructions for restoring the deck to perfection are provided.

Deck repairs are complicated by the necessity of providing effective nonskid surfaces. Owners of boats with molded-in nonskid will find the included instructions for renewing those surfaces useful. Those with planked decks will be more interested in the section detailing the care and repair of teak overlay.

Eventually, of course, a hull-and-deck-repair book for fiberglass boats must come around to repairs requiring fiberglass lay-up, but not without first providing clear and concise descriptions of the various materials to be used. When should you use polyester resin and when epoxy? What is vinylester? Cloth, mat, or roving? You will find answers to these questions and more in Chapter 4.

Armed with an understanding of the materials involved and guided by clear illustrations, you are ready to take on more complicated repairs. Chapter 5 shows you how to repair deck delamination and how to replace spongy core. Chapter 6 focuses on hull repairsdealing with gouges, repairing blisters, and reconstructing after impact damage. A quick look in Chapter 7 at repairing common rudder and keel problems, and you will have taken the cannon.

When all boats were built of wood, a truly professional repair required the skills of someone with years of experience. Not so with fiberglass. Pay attention and give it a try, and you will discover that there is virtually no repair to a fiberglass hull or deck that a motivated owner cant do as well (if not as quickly) as a pro.

Frozen snot, indeed!

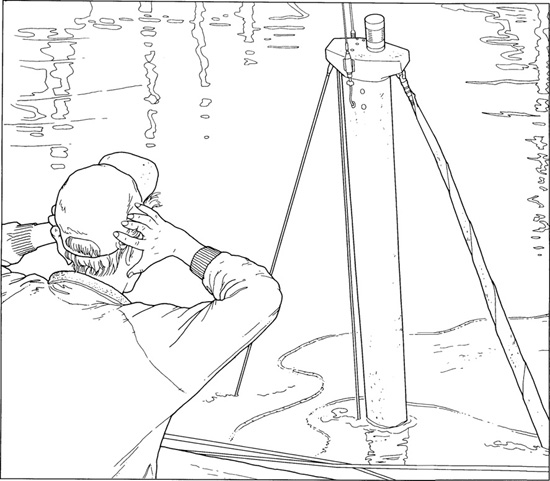

LEAKS

Leaks are insidious. A tiny leak, left unattended for months or years, can easily result in damage that will cost thousands of dollars to have repaired, or take innumerable hours if you make the repairs yourself.

There are the obvious things: ruined interior varnish below leaking ports, mildewed upholstery from trickles from the hull-to-deck joint, a punky cabin sole from mysterious rainwater intrusion.

As serious as these are, theyre small potatoes. The biggest risk from leaks is to the deck core, and you may not see any evidence of a leak until major damage is already done.

Next page