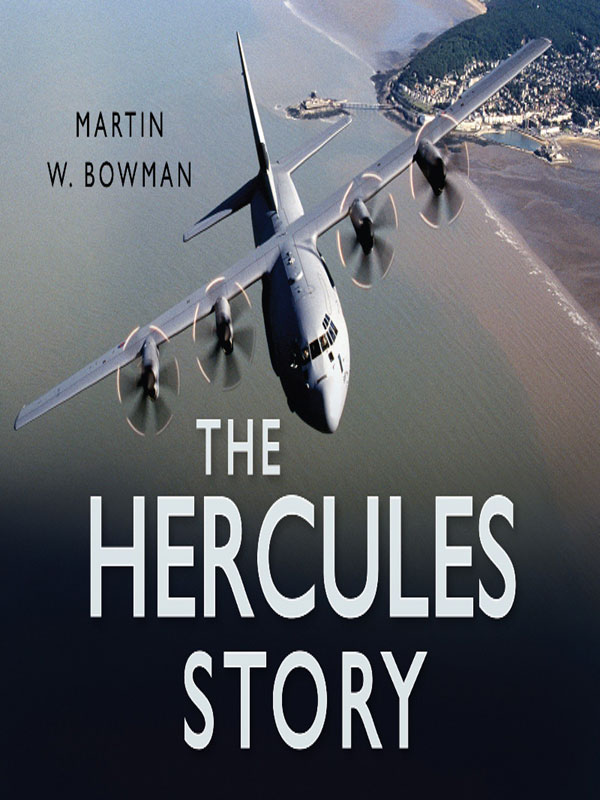

The Hercules Story

Martin W. Bowman

First published in 2009

The History Press

The Mill, Brimscombe Port

Stroud, Gloucestershire, GL5 2QG

www.thehistorypress.co.uk

This ebook edition first published in 2014

All rights reserved

Martin W. Bowman, 2009, 2012, 2014

Martin W. Bowman has asserted the moral right to be identified as the author of this work.

This ebook is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

EPUB ISBN 978 0 7524 8508 9

MOBI ISBN 978 0 7524 8507 2

Original typesetting by The History Press

CONTENTS

INTRODUCTION

I n the years since the Vietnam War, the Herky bird has written its own chapter in aviation history as the worlds most successful military airlifter. When military cargo and heavy equipment have to be delivered into trouble zones soldiers and paratroops, pen-plc, relief supplies and medical aid or they need to be evacuated from war and famine, then the success of the operation depends on this immensely reliable and versatile craft. When there are labours to be done, whether military support or international relief, the Hercules is usually there, swirling the dust in the middle of desert wastes, being put down on remote jungle strips, or landing on bomb-scarred runways at war-ravaged airports, delivering cargo or air-dropping supplies.

The Hercules has come to the aid of countless thousands in every part of the world. While it can be uncomfortable, especially back in the hold, the rugged, simple construction was designed from the outset to operate from rough or semi-prepared grass or sand strips with the minimum of support.

The Hercules has never been far from the front line. It has continued to prove itself a most flexible workhorse. Since it first took to the skies on 13 August 1954, Herky birds have operated as transporters, gunships, bombers, air-to-air refuellers, airborne command posts, AWACs, firefighters and even airborne hospitals.

Between 1962 and 1975, Lockheed delivered more than 700 Hercules to air forces throughout the world. In April 1994 more than 2,100 models of the Hercules had been sold to over sixty-six countries. When the millennium arrived, the Hercules had been in continuous production for over forty-five years, through at least eighty-five original and modified versions. What about that for versatility! Of one thing we can be certain, and that is that those who are fortunate to have worked with and flown on the Hercules can look back with a deep sense of pride at an airlifter that is without equals.

BACKGROUND

O n 2 February 1951, the USAF issued a request for proposals (RFP) to Boeing, Douglas, Fairchild and Lockheed for a medium-size transport complying with a specially prepared General Operational Requirement (GOR). Experience in Korea, where war had broken out in June 1950, revealed serious operational limitations in the Fairchild C-119 tactical troop and cargo transport. A USAF colonel was reported to have said that what the Air Force really needed was an aircraft that could carry a 30,000lb payload of freight or troops over a distance of 1,500 nautical miles, and could land and take off from difficult terrain. It was a feat, almost impossible to achieve at the time, but sources predicted that the winner of the GOR could ultimately expect to build as many as 2,000 aircraft. The new medium-size transport had to be able to carry ninety-two infantrymen or sixty-four paratroopers over 2,000 miles for tactical missions, or for logistic missions a 30,000lb load (including bulldozers, trucks, road-graders and howitzers) over 950 nautical miles (all without refuelling). It had to operate, if required, from short and unprepared airstrips; and it had to be capable of slowing down to 125 knots for paradrops through two side doors, and even more slowly for steep assault landings. It also had to perform with one engine out over the drop zone. At Lockheed-Burbank, Art Flock and his design team, under the supervision of Willis Hawkins, head of the advanced design department, went to work on temporary design designation L-206. Hawkins said that the new aircraft would have to be an amalgam of jeep, truck and aircraft. Although it was intended as a medium-sized tactical transport, Flock opted for four engines instead of two, which would make the L-206 more expensive than its competitors. No turbine-powered transports had ever been produced in the USA before, but the slim-line 3,750eshp Allison T56-A-1A turbine was selected. The L-206s top speed of 360mph would be faster than any other tactical transport then existing. Its basic mission weight was only 108,000lb due to the widespread use of machined skins with integral stiffening which largely eliminated riveting, and high-strength aluminum alloy was used throughout to strengthen the aircrafts overall structure.

Hercules also featured a 41ft 5in-long cargo compartment of nearly square cross-section for total volume of 4,500 cubic feet. To achieve ease of loading and unloading, the cargo floor was only 34ft off the ground, or at truck-bed height. The inward-opening top half of the cargo door allowed the Hercules to airdrop equipment and cargo the width of the cargo compartment. In addition to a rear ramp, an upward-hinged door was situated on the port side of the fuselage, just aft of the crew entrance door, and there were also paratroop doors on both sides of the rear fuselage, just forward of the ramp. The entire plane had to be pressurized to carry sixty-four paratroops, seventy-eight ground troops or seventy-four litter patients and two medical attendants (or seventy litters and six attendants) for casevac duties. Above the blunt nose, a spacious flight deck accommodated two pilots, a navigator and a systems manager (a loadmaster made up the fifth member of the crew) in a greenhouse with twenty-three windows designed to give 20 of all-round visibility, especially during landings at rudimentary airstrips. A strong undercarriage had tandem main landing-gear wheels, which retracted into fairings on the sides of the fuselage. A 132ft-span, high-aspect ratio, angular wing was laid across a flat fuselage and provided excellent ground clearance. The 38ft-high vertical stabilizer was designed to offer easy access to the aft fuselage, and would also permit pilots good control response on low-speed approaches.

The Lockheed proposal was submitted in April 1951 and on 2 July was declared the winner. A contract was awarded for two YC-130 (Model 82) prototype/service-test aircraft, to be built at Burbank, and seven production aircraft (Model 182) to be built at Marietta, Georgia. Al Brown was chosen as C-130 project engineer. The first C-130 prototype (1001/53-3396) was used initially for static tests. The second YC-130 prototype first flew on 23 August 1954, and was airborne within 800ft from the beginning of its take-off roll, and the sixty-one-minute flight to Edwards AFB, in the Mojave Desert, California, was made without hitch. In 1954 orders for sixty-eight more C-130As were received. The C-130A differed from the YC-130s principally in having provision for two 450 US gallon external fuel tanks outboard of the outer engines, but it was also driven by more powerful T56 engines. The first twenty-seven aircraft were delivered without a nose radome, but were later modified to carry search radar. The first production C-130A-LM (53-3129) was rolled out at Marietta on 10 March 1955. Chief pilot Bud Martin and co-pilot Leo Sullivan flew it on 7 April 1955.