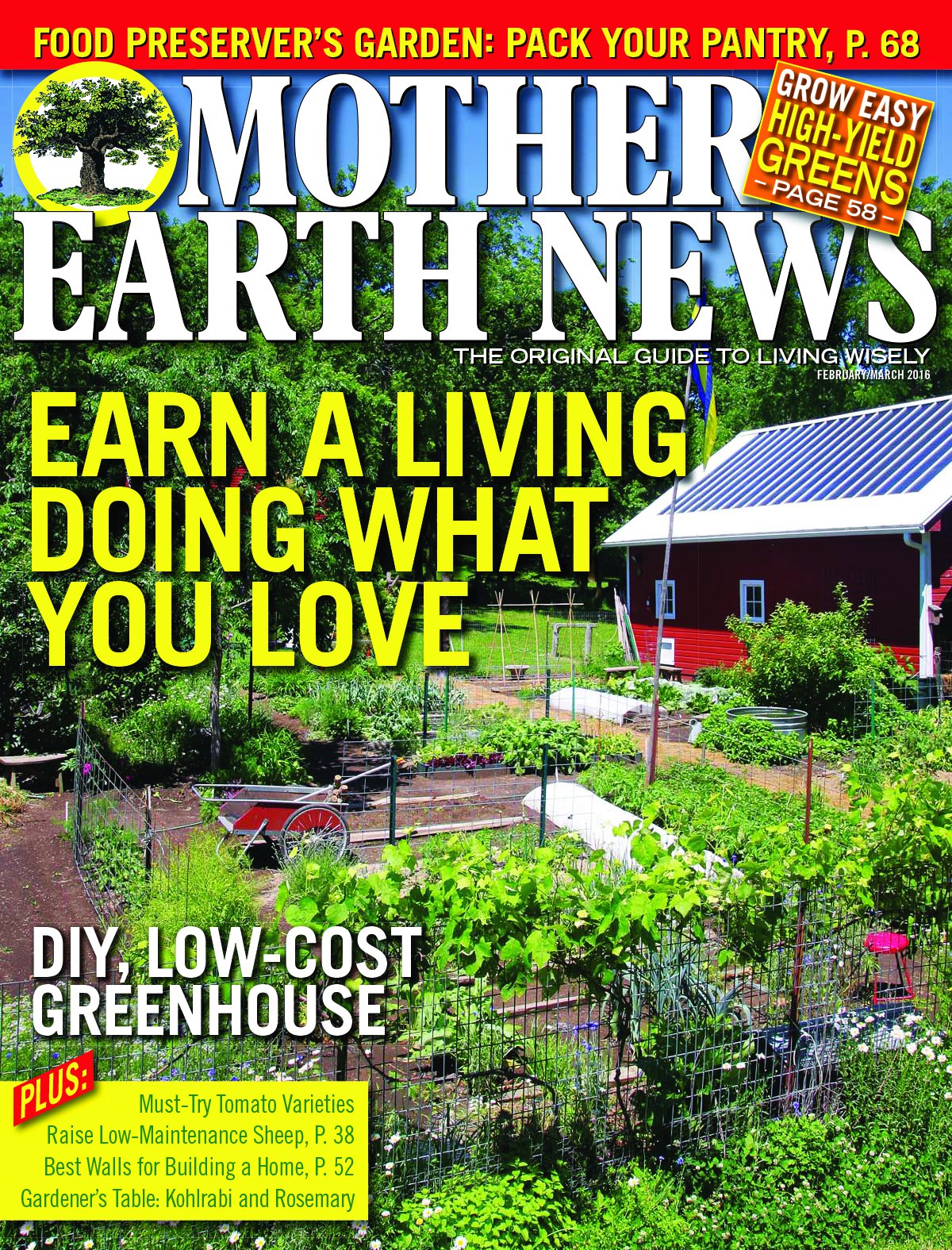

Mother Earth News - Mother Earth News 2016

Here you can read online Mother Earth News - Mother Earth News 2016 full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2016, publisher: Mother Earth News, genre: Science / Home and family. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Mother Earth News 2016

- Author:

- Publisher:Mother Earth News

- Genre:

- Year:2016

- Rating:5 / 5

- Favourites:Add to favourites

- Your mark:

- 100

- 1

- 2

- 3

- 4

- 5

Mother Earth News 2016: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Mother Earth News 2016" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Mother Earth News 2016 — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Mother Earth News 2016" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

In the sustainable home building industry, many prospective homeowners want to make environmentally friendly choices, but struggle to make sense of a building industry that labels every house framing option as green. For environmentally conscious builders, like me, sustainable construction encompasses many factors, including ecosystem impacts, carbon footprint, material waste, energy efficiency, cost, durability and indoor air quality. Ultimately, those sustainability considerations must mesh with practical concerns, such as labor, building compliance, and material sourcing and availability. One measurement that helps builders and future homeowners compare various materials environmental impact, embodied energy (EE), totals the amount of energy invested in a product during sourcing, shipping and installation. Further, when sustainable home builders include the energy associated with a materials use and disposal, or that products downstream, they have completed a life cycle impact assessment. Now, no house framing system neither cob, compressed earth blocks, straw bale, nor wood frame scores top marks in all criteria, and embodied energy and life cycle analyses differ based on site-specific circumstances, so homebuilders must determine their priorities and make choices that best reflect those goals. One size never fits all in green building.

House framing systems are often the first thing an owner-builder wants to discuss. And no wonder: Walls support the windows and doors that physically define a space, play a crucial role in a homes energy efficiency, and dominate a buildings aesthetic.

To help homeowners refine their ideas into buildable homes, I created these charts: Wall-Framing Systems and Conventional vs. Improved Wood Framing. The charts compare five house framing systems systems according to 11 criteria, and show how each system rates relative to the others. Many people assume that alternative wall systems (such as straw bale, cob and compressed earth block) are more sustainable choices, but if you study this chart, youll see that wood-framed walls perform well when paired with improved materials.

In the 20 years since the resurgence of interest in straw bale building, the number of houses raised using this type of so-called alternative construction has grown quickly. Straw bale building is one of the few alternatives with comprehensive code language, and the International Residential Code incorporated straw bale walls in 2015 a fast ascent from fringe following to mainstream acceptance.

In straw bale building, workers stack bound, rectangular bales of leftover stalks from grain crops (such as wheat, rice, oats, barley and even hemp) to form walls (see photo). The exposed surfaces require a coating of clay, lime or cement-lime plaster to provide external structure, seal and finish. Straw bale walls easily adapt to many aesthetic possibilities the material is equally at home in straight, square buildings as it is in round or curvy structures.

Accurately rating straw bale walls can be difficult because numerous building systems incorporate straw bales, but differ greatly in process and materials. For example, simple, load-bearing straw bale wall systems score well when builders choose minimal window and door framing, a simple wooden top plate, and site-made earthen plaster (see Wall-Framing Systems chart). However, when straw bale builders use complex framing systems with plaster mesh and cement-based plasters, they significantly raise environmental impacts, along with financial and labor input.

Finally, because straw bale systems typically pair lower-cost materials with higher labor needs than conventional building methods, costs vary widely depending on the source and price of that labor.

Cob building has ancient roots, and most cultures have engaged in some form of this building style. Cob is a mixture of clay-rich soil with sand and natural fiber, most often straw or grasses. The wetted blend forms a dense, sculptable medium that builders hand-form into walls (see photo). This simple process works well with a wide range of materials and in a wide variety of climates. Finally, cob builders often apply a protective layer of clay-based plaster to the finished walls.

Although cob currently lacks explicit building code language in North America, hence the materials low scores in the categories of building-code-compliance and labor-input, some smaller cob structures are legally permissible because of size exemptions. Cob also scores poorly in energy efficiency, thus the need for additional insulation in all but the most temperate climates.

To address efficiency concerns, homebuilders should incorporate other insulating materials into a cob wall, either in the form of a double-wall construction with insulation in the center, or some type of exterior or interior insulation and cladding. Insulation choices can dramatically affect a cob walls ratings, increasing both the cost and environmental impact.

Constructing an energy-efficient cob home is certainly possible, however, as is lowering labor requirements by using mechanical equipment. But, improvements in those areas will detract from the low-cost, low-impact simplicity that draws many builders to cob construction in the first place.

Of all the alternative wall-framing systems, cob has the least amount of data available to support building-permit applications, though some prominent cob homes have set a promising precedent.

Cordwood building makes use of wood resources unsuitable for log or milled-lumber construction. Builders stack short pieces of round or split wood lengthwise across a wall, [as the length of the pieces determines the walls thickness (see photo).] For structural support, a bed of mortar made from clay, lime or cement forms a structural matrix around the wood pieces. The mortar reinforces the wood on the inner and outer edges of the wall, leaving inner-wall cavities around the wood that can be filled with insulation.

Like straw bale building, cordwood walls net a wide range of scores in the chart below, depending on decisions builders make before and during construction. While wood sourcing has some effect on environmental impact, a cordwood builders mortar and insulation material choices are the largest influencing factor on sustainability.

Cordwood is prone to air leakage, which greatly affects its energy efficiency. Providing an adequate air seal at the many joints between wood and mortar can be difficult, but any leaks can negate insulation improvements added to the walls. Coating both sides of the walls in plaster (or another sheathing) will improve thermal performance levels significantly, but will change the aesthetic and add to the costs.

While cordwood walls arent formally recognized by any building codes, historical and modern precedents contribute to the availability of permits in many jurisdictions.

Contemporary compressed earth blocks (CEBs) use mechanical- or hydraulic-powered presses to tamp soil with low clay content into large bricks, drawing on the ancient, rammed earth building techniques. In many cases, builders bring block-making machinery to the building site to use the sites soil as the basis for the blocks; however, some commercial CEB producers form blocks at a central plant for shipping. Once formed, compressed earth blocks are laid up like concrete blocks, using clay- or lime-based mortar to bond the blocks together.

Font size:

Interval:

Bookmark:

Similar books «Mother Earth News 2016»

Look at similar books to Mother Earth News 2016. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Mother Earth News 2016 and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.