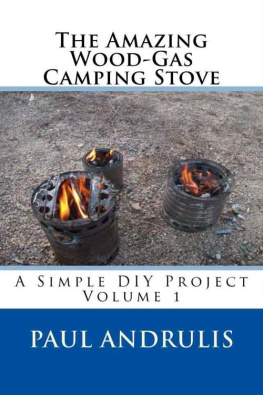

The Amazing Wood-Gas Camping Stove

A simple DIY Project

By Paul Andrulis

Copyright 2012 By Paul Andrulis

All rights reserved under International and Pan-American Copyright Conventions.

Dedications:

This book is dedicated to my beloved wife Melissa, without whose encouragement this work would never have been possible.

Table of Contents:

Introduction:

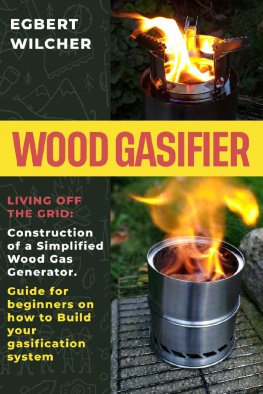

Are you tired of cooking over a campfire and choking on the thick smoke? Maybe you are frustrated with large heavy stoves, and the accompanying bulky and expensive fuel? Let me introduce you to the Wood-Gas stove!

The Wood-Gas stove, also called a 'wood gasifier' stove is relatively easy to build, cheap or even free to make, and both easy and reliable to use. Best of all, the fuel itself is absolutely free, provided for your use inevitably wherever you have chosen to camp. Though wood will be a common choice for fuel, any dense, vegetative based, dry fuel (often called biomass) will operate these units.

The smallest unit on the cover page was capable of perking a half-gallon of coffee using only nine pine-cones for total fuel. Wood-Gas stoves are by nature very efficient and economical in fuel use, emitting very little to no smoke during operation, and leaving a ridiculously small amount of very fine grained powder ash residue. Over all, a light weight, economical, and an overall worthwhile addition to any camping backpack, outdoors cooking set, or emergency preparedness kit. These stoves are good for personal use, make great gifts, and can even make you some extra cash if you so desire. They are so fascinating to see demonstrated that the viewer invariably wants one.

Chapter 1: What exactly is a gasifier (wood-gas) stove?

A 'wood-gas' stove is, technically speaking, a stove based upon the process of pyrolitic decomposition of biomass substances in a low oxygen environment into the flammable gases carbon monoxide, methane, oxygen and hydrogen, and the inflammable gases nitrogen and carbon dioxide. The byproducts of a completely 100% efficient device are water, carbon dioxide, heat, and pure mineral ash. It is called a wood- GAS stove due to the fact that it burns the gas produced by pyrolysis of the wood, and not the wood directly. Further explanation in much simpler terms concerning the theory of operation is provided in chapter 2.

The particular type of stove I work with, and provide in this book instructions to build, is a 'modified coaxial downdraft gasification stove'. Through years of experimentation with the design, I have never achieved 100% efficiency, though I have come very close. This estimation is based upon the amounts of pure ash, and amounts of gaseous byproducts left unburnt, such tar (soot) residue left on cooking implements.

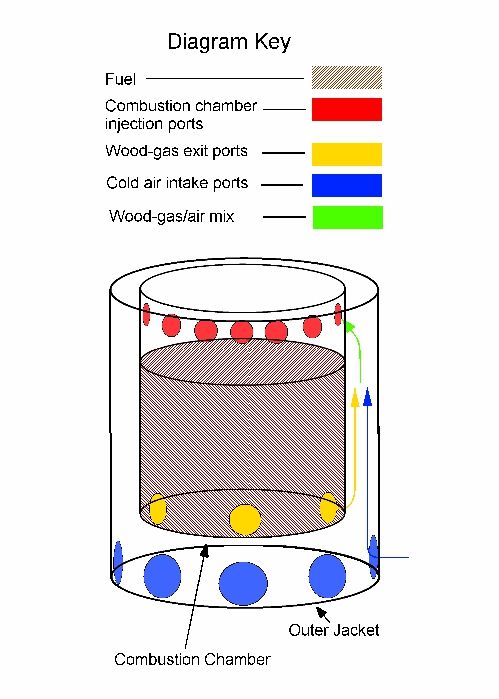

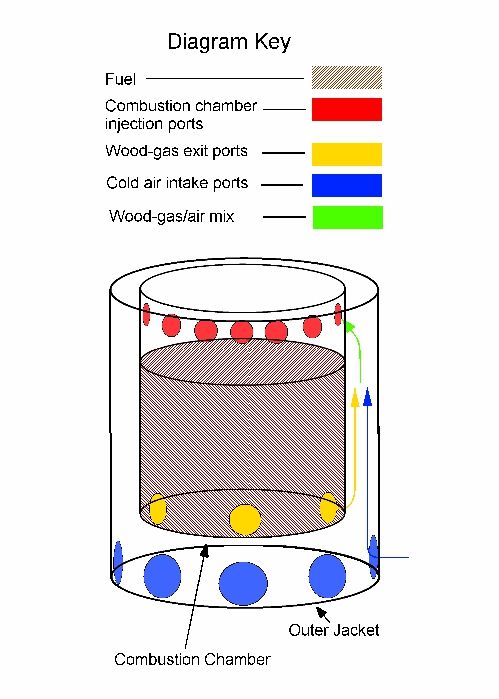

The stove consists of two parts. An outer can which shall be called the Outer Jacket, and a smaller inner can which is the Combustion Chamber where the pyrolysis occurs. A hole is cut into the bottom of the inverted Outer Jacket, and the inner Combustion Chamber fits snugly through this hole, leaving a distance of 3/8 to 1/2 air gap between the two cans. The outer jacket sits on the ground, while the smaller combustion chamber should ride at least 1/2 to 3/4 above the ground.

Chapter 2: How does a gasifier stove work?

A gasifier stove works not by burning wood directly like most wood burning stoves, but by heating wood in the Combustion Chamber until it chemically breaks down into combustible gases. This is the process of 'pyrolysis', or the molecular breakdown of a complex molecule into simpler molecules through the application of heat. These flammable gases are forced out through holes in the side of the combustion chamber towards the bottom into the space between the outer jacket and the combustion chamber. Heat from the combustion chamber causes air to be sucked in through holes in the bottom of the outer jacket which mixes with the flammable gases coming from the combustion chamber. The cold air/hot flammable gas mixture is then forced up between the outer jacket and the combustion chamber through convection.

As it is forced up between the two cans, the mixture gains additional heat from the combustion chamber which super heats the mix. After it exits the gas injection holes in the top of the combustion chamber, the mixture ignites, and causes the signature flame pattern of a gasifier stove, which you will notice in the following photograph.

Though the stove pictured is gasifying properly and no visible smoke is present, it is not one hundred percent efficient. Technically, at 100% efficiency there are no loose carbon based tars or soot present as all long chain carbon molecules would be broken down and after ignition converted to carbon dioxide and water. Yet after use, some tar will appear on the bottom of the cooking vessel indicating unburnt long chain carbon molecules.

A good 'rule of thumb' is simply the more efficient the stove design, the less tar or 'soot' will be present on the cooking utensils after use. In a downdraft design such as this, I do not think at this time 100% efficiency is attainable, though I estimate that 80 - 90% is. Some designs are supposedly more efficient, but are either much harder to construct, much larger, complex, and/or heavier, all making them unsuitable for practical use as a camping stove. Even though it is not completely efficient, no smoke is either visible nor is there a smell of smoke in the air. A large chamber full of wood leaves a light dusting of extremely fine powder wood ash. One other consideration; much less soot is deposited on pans than would be evident from a regular wood fire.

All 'downdraft' wood-gas stoves burn the fuel in the Combustion Chamber from the top down. The inner Combustion Chamber is filled with fuel such as short pieces of stick, chunks of bark, whole pine cones, etc., up to the row of the Combustion Chamber's top inlet holes. A small fire is started on top to initiate the pyrolysis process. When the heat generated is sufficient to initiate the pyrolysis reaction, the flame from the ordinary wood fire extinguishes, leaving red hot coals which sustain the fuel consumption. At this point the flames come not from the fuel below, but as shown in the previous photograph from the gases entering the Combustion Chamber through the inlet holes. The following diagram shows the basic stove design and function.

As a general design rule, the Combustion Chamber should be tall and thin in comparison to the overall stove dimensions, not short and fat. A 'short and fat' Combustion Chamber does not properly gasify the carbon material within. It also does not provide enough travel time for the cold air/wood-gas mixture to heat properly for good convection to occur. This means the stove has a weak draft and therefore an improper cold air/wood-gas mixture ratio, ultimately leading to a carbonizing (smoky) flame and lower cooking energy.

Chapter 3: What are the benefits of a gasifier stove?

If I were to list merely the benefits of the stove, I feel that I would not be giving my readers an honest and unbiased evaluation. Therefore let us examine all of the benefits, as well as any detraction, in comparison to other common stove types or even an open fire.

Gasifier stove:

- Maintenance: None

- Fuel: Biomass (wood, bark, woody plant stalks, pine cones, etc.,).

- Size: Small to large. Easily scalable to desired size.

- Weight: Lightweight even in larger sizes. No pack fuel weight.

- Cost of stove: Inexpensive (new cans), or free (used cans).

Next page