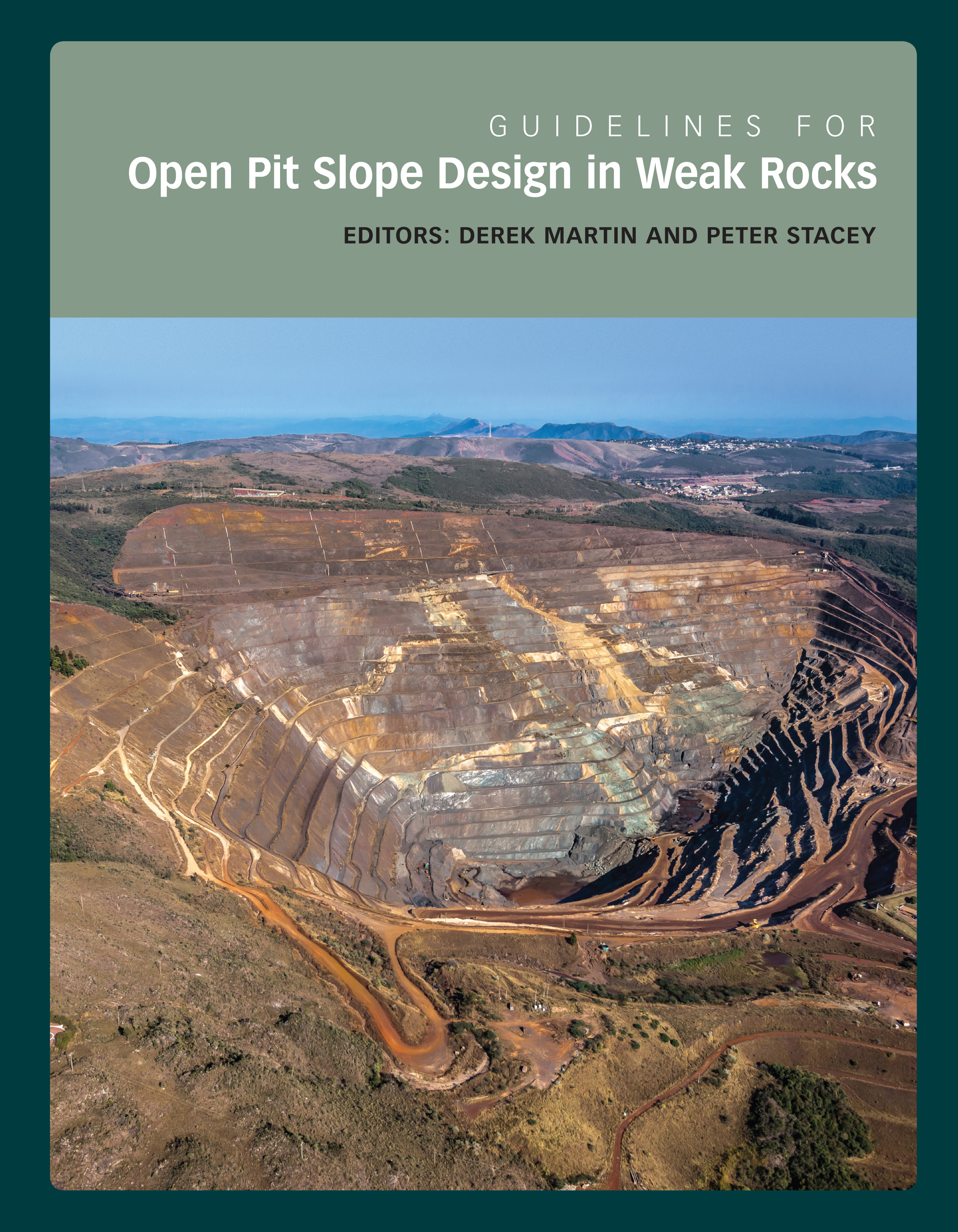

The publication Guidelines for Open Pit Slope Design was produced in 2009 as an outcome of the Large Open Pit (LOP) project managed by CSIRO and sponsored by major mining companies. The main focus of the LOP is international research and technology transfer focusing on the stability of rock slopes in open pit mines. The preface to the 2009 Guidelines state:

The purpose of the Guidelines was to link innovative mining geomechanics research with best practice. It is not intended for it to be an instruction manual for geotechnical engineering in open pit mines. Rather, it aspires to be an up-to-date compendium of knowledge that creates a road map which, from the options that are available, highlights what is needed to satisfy best practice with respect to pit slope investigation, design, implementation, and performance monitoring. The fundamental objective is to provide the slope design practitioner with the tools to help meet the mine owners requirements that the slopes should be stable, but if they do fail the predicted returns on the investment are achieved without loss of life, injury, equipment damage, or sustained losses of production.

It was recognised by the LOP Sponsors Management Committee that the Guidelines were focused primarily on open pit slopes in strong rocks as defined by the International Society for Rock Mechanics (ISRM) strength classification (i.e. a grade of R2). As such, it did not fully consider the challenges that are often associated with open pits in weak rocks (R0 to R2). Some of the challenges faced by the mining geotechnical practitioner are:

insufficient experience in similar geotechnical environments

insufficient experience in similar geotechnical environments

representative sampling and testing of materials which conform to the hybrid engineering behaviour associated with both soil and rock

representative sampling and testing of materials which conform to the hybrid engineering behaviour associated with both soil and rock

identifying commercial laboratories with expertise in testing these materials

identifying commercial laboratories with expertise in testing these materials

derivation of a representative shear strength

derivation of a representative shear strength

understanding the sensitivity of shear strength to moisture content, stress history and stress change

understanding the sensitivity of shear strength to moisture content, stress history and stress change

poorly defined and/or researched material constitutive behaviour for large scale unloading

poorly defined and/or researched material constitutive behaviour for large scale unloading

the role of negative (suction) and positive (excess) pore pressures on shear strength for large slopes in weak rocks

the role of negative (suction) and positive (excess) pore pressures on shear strength for large slopes in weak rocks

complex, time dependent behaviour

complex, time dependent behaviour

managing highly anisotropic geotechnical behaviour

managing highly anisotropic geotechnical behaviour

understanding the role of, and identifying, remnant or paleo-structures on stability.

understanding the role of, and identifying, remnant or paleo-structures on stability.

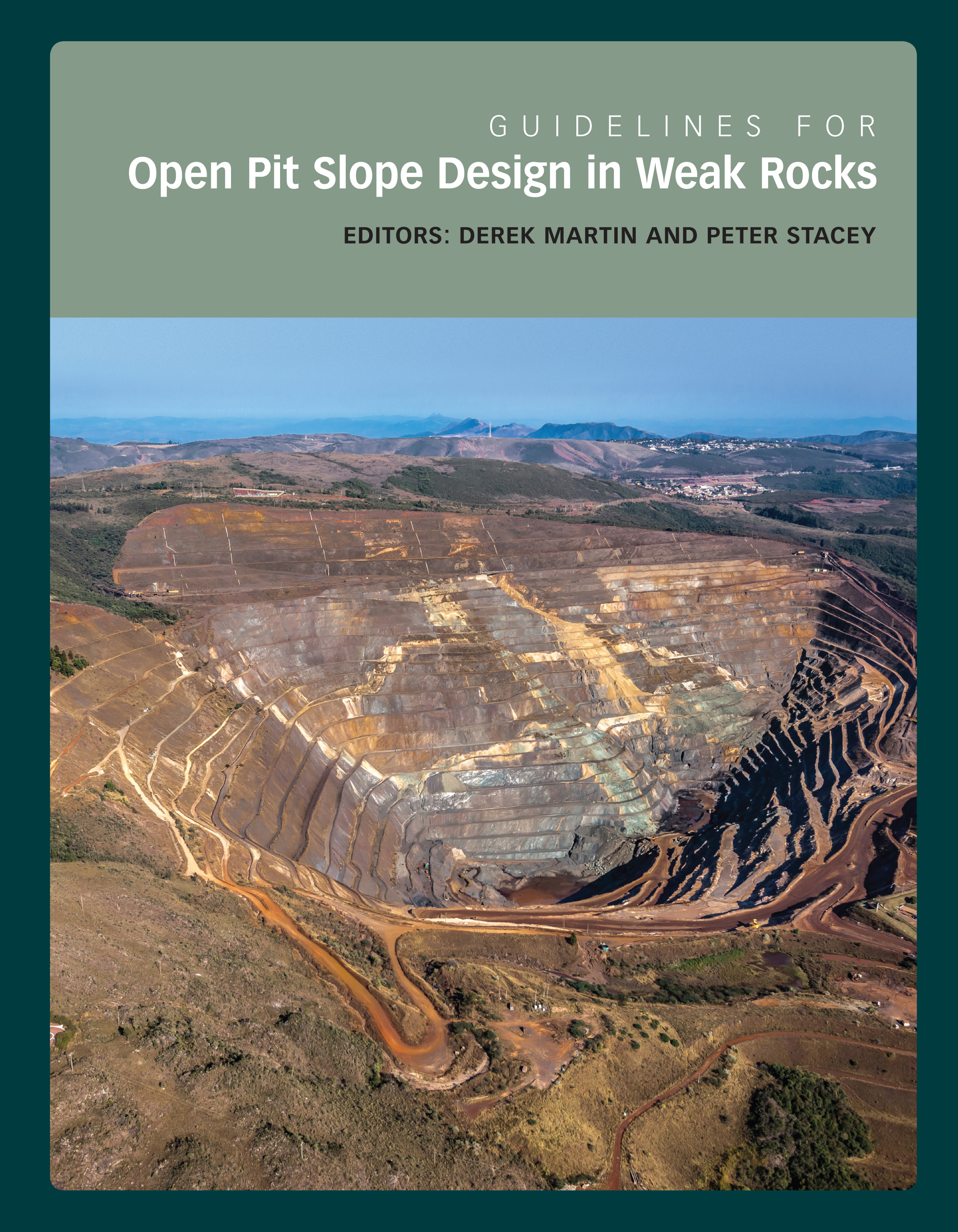

With the increasing efficiency of mining equipment, the possibility of mining significant thicknesses of un-mineralised overburden, particularly over large low-grade orebodies, is increasing. As a result, pit walls several hundred metres deep have been developed in weak rock and an increasing number are planned. In these pits, failures can have a major impact from both the safety and economy perspectives, as illustrated in

Weak rocks typically require flatter excavated slope angles than are adopted in strong rocks, and these flatter slopes will have significant economic impacts. It is therefore critical that the presence of weak rocks is recognised early in the project development process, because the pit slope design process will not be the same as for strong rocks, and may require a different site characterisation and design approach. This book has therefore been prepared as an addendum to the original Guidelines with the specific purpose of providing a framework for characterising, analysing and designing pit slopes in weak rocks. For the sake of completeness, certain sections of the 2009 Guidelines have been repeated in this addendum, in an attempt to provide a stand-alone text for the practitioner, who may be working in a remote mine.

Figure 1.1 Example of a pit slope failure in the weak rock overburden (photo courtesy of Barrick).

The term weak rocks in the International Society for Rock Mechanics (ISRM) classification comprises rock with intact strengths ranging from extremely weak (R0) to weak (R2), with equivalent Uniaxial Compressive Strengths (UCS) ranging from 250 kPa to 25 MPa, respectively (.

The five weak rock categories that will be dealt with in these Guidelines (which represent the most common encountered in LOP sponsors operations) are:

1. Cemented sediments

(a) bedded cemented sediments

(b) cemented gravels

2. Weak sedimentary rocks

(a) mudrocks and lake bed sediments

(b) chalk and limestones

(c) coals

3. Saprolites (weathered rocks and residual soils)

4. Soft iron ores and leached rocks (high void ratio leached rocks)

(a) weathered and leached iron ores and associated altered country rocks

(b) leached quartzites

5. Hydrothermally altered rocks.

These five weak rock categories, illustrated in , can be divided into two broad geographical groupings, namely:

those formed of material that has been transported from elsewhere and deposited either underwater or sub-aerially. Cemented sediments (e.g. alluvium or colluvium) and weak sedimentary rocks fall into this group.

those formed of material that has been transported from elsewhere and deposited either underwater or sub-aerially. Cemented sediments (e.g. alluvium or colluvium) and weak sedimentary rocks fall into this group.

those that have been derived from the in-situ alteration of a parent rock, including saprolites, leached rocks (e.g. soft iron ores) and hydrothermally altered rocks.

those that have been derived from the in-situ alteration of a parent rock, including saprolites, leached rocks (e.g. soft iron ores) and hydrothermally altered rocks.

Within the five weak rock categories, the LOP sponsors case histories indicated that many of the failures occurred through the rock mass without any discrete geological structure playing a dominating role. However, when geological features were present, such as contacts, foliation, bedding and structure, these features had influence on the mode of failure, often as a secondary process. Within the LOP case histories, regardless of the mode of failure, the dominating failure kinematics were either circular or planar failure, with wedge and toppling failures playing a minor role, as shown in . The dominating modes of failure highlight an important difference between weak rocks and strong rocks. In strong rocks, geological structure is almost always ubiquitous and nearly all major failures are controlled by structure. In weak rocks, ubiquitous structures may be absent, and hence, the rock mass can play a dominating role. However, when geological structure is present, it will be weaker than the rock mass and, as with strong rocks, may control the mode of failure. Detecting random geological structure in weak rocks challenges the site investigation strategy for these materials.

In a mining context, weak rocks often form the near-surface materials that may be encountered when developing an open pit. They can range in thickness up to, although the protolith may be considerably older, as in the case of soft iron ores and some saprolites. In addition, most weak rocks have existed in relatively stable tectonic environments in which erosional forces have been limited.

Next page

insufficient experience in similar geotechnical environments

insufficient experience in similar geotechnical environments