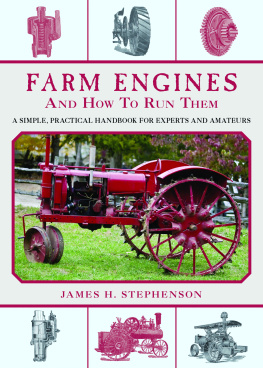

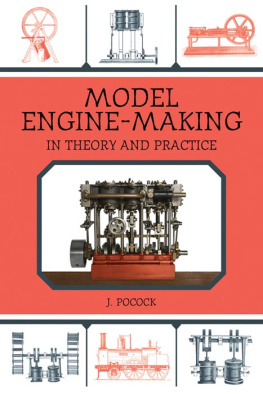

F ARM E NGINES

A ND H OW TO R UN T HEM

F ARM E NGINES

A ND H OW TO R UN T HEM

A Simple, Practical Handbook for Experts and Amateurs

J AMES H. S TEPHENSON

Copyright 2013 by Skyhorse Publishing, Inc.

This is a facsimile of the original edition, first published in 1903. Skyhorse is committed to preserving works of cultural importance and, as such, has elected to keep the text as close to the original as possible, despite some imperfections. Though the editors have made minor adjustments to fill in missing or severely damaged text, none of the original characters or language have been altered.

All Rights Reserved. No part of this book may be reproduced in any manner without the express written consent of the publisher, except in the case of brief excerpts in critical reviews or articles. All inquiries should be addressed to Skyhorse Publishing, 307 West 36th Street, 11th Floor, New York, NY 10018.

Skyhorse Publishing books may be purchased in bulk at special discounts for sales promotion, corporate gifts, fund-raising, or educational purposes. Special editions can also be created to specifications. For details, contact the Special Sales Department, Skyhorse Publishing, 307 West 36th Street, 11th Floor, New York, NY 10018 or info@skyhorsepublishing.com.

Skyhorse and Skyhorse Publishing are registered trademarks of Skyhorse Publishing, Inc., a Delaware corporation.

Visit our website at www.skyhorsepublishing.com.

10 9 8 7 6 5 4 3 2 1

Library of Congress Cataloging-in-Publication Data is available on file.

ISBN: 978-1-62087-058-7

Printed in the United States of America

PREFACE

This book makes no pretensions to originality. It has taken the best from every source. The author believes the matter has been arranged in a more simple and effective manner, and that more information has been crowded into these pages than will be found within the pages of any similar book.

The professional engineer, in writing a book for young engineers, is likely to forget that the novice is unfamiliar with many terms which are like daily bread to him. The present writers have tried to avoid that pitfall, and to define each term as it naturally needs definition. Moreover, the description of parts and the definitions of terms have preceded any suggestions on operation, the authors believing that the young engineer should become thoroughly familiar with his engine and its manner of working, before he is told what is best to do and not to do. If he is forced on too fast he is likely to get mixed. The test questions at the end of Chapter III will show how perfectly the preceding pages have been mastered, and the student is not ready to go on till he can answer all these questions readily.

The system of questions and answers has its uses and its limitations. The authors have tried to use that system where it would do most good, and employ the straight narrative discussion method where questions could not help and would only interrupt the progress of thought. Little technical matter has been introduced, and that only for practical purposes. The authors have had traction engines in mind for the most part, but the directions will apply equally well to any kind of steam engine.

The thanks of the publishers are due to the various traction engine and threshing machine manufacturers for cuts and information, and especially to the Threshermens Review for ideas contained in its Farm Engine Economy, to the J. I. Case Threshing Machine Co. for the use of copyrighted matter in their The Science of Successful Threshing, and to the manager of the Columbus Machine Co. for valuable personal information furnished the authors on gasoline engines and how to rim them. The proof has been read and corrected by Mr. T. R. Butman, known in Chicago for 25 years as one of the leading experts on engines and boilers, especially boilers.

THE

YOUNG ENGINEERS GUIDE

CHAPTER I.

BUYING AN ENGINE.

There are a great many makes of good engines on the market to-day, and the competition is so keen that no engine maker can afford to turn out a very poor engine. This is especially true of traction engines. The different styles and types all have their advantages, and are good in their way. For all that, one good engine may be valueless for you, and there are many ways in which you may make a great mistake in purchasing an engine. The following points will help you to choose wisely:

1. Consider what you want an engine for. If it is a stationary engine, consider the work to be done, the space it is to occupy, and what conveniences will save your time. Remember, TIME IS MONEY, and that means that SPACE IS ALSO MONEY. Choose the kind of engine that will be most convenient for the position in which you wish to place it and the purpose or purposes for which you wish to use it. If buying a traction engine, consider also the roads and an engines pulling qualities.

2. If you are buying a traction engine for threshing, the first thing to consider is FUEL. Which will be cheapest for you, wood, coal, or straw? Is economy of fuel much of an object with youone that will justify you in greater care and more scientific study of your engine? Other things being equal, the direct flue, fire box, locomotive boiler and simple engine will be the best, since they are the easiest to operate. They are not the most economical under favorable conditions, but a return flue boiler and a compound engine will cost you far more than the possible saving of fuel unless you manage them in a scientific way. Indeed, if not rightly managed they will waste more fuel than the direct flue locomotive boiler and the simple engine.

3. Do not try to economize on the size of your boiler, and at the same time never get too large an engine. If a 6-horse power boiler will just do your work, an 8-horse power will do it better and more economically, because you wont be overworking it all the time. Engines should seldom be crowded. At the same time you never know when you may want a higher capacity than you have, or how much you may lose by not having it. Of course you dont want an engine and boiler that are too big, but you should always allow a fair margin above your anticipated requirements.

4. Do not try to economize on appliances. You should have a good pump, a good injector, a good heater, an extra steam gauge, an extra fusible plug ready to put in, a flue expander and a beader. You should also certainly have a good force pump and hose to clean the boiler, and the best oil and grease you can get. Never believe the man who tells you that something not quite the best is just as good. You will find it the most expensive thing you ever triedif you have wit enough to find out how expensive it is.

5. If you want my personal advice on the proper engine to select for various purposes, I should say by all means get a gasoline engine for small powers about the farm, such as pumping, etc. It is the quickest to start, by far the most economical to operate, and the simplest to manage. The day of the small steam engine is past and will never return, and ten gasoline engines of this kind are sold for every steam engine put out. If you want a traction engine for threshing, etc., stick to steam. Gasoline engines are not very good hill climbers because the application of power is not steady enough; they are not very good to get out of mud holes with for the same reason, and as yet they are not perfected for such purposes. You might use a portable gasoline engine, however, though the application of power is not as steady as with steam and the flywheels are heavy. In choosing a traction steam engine, the direct flue locomotive boiler and simple engine, though theoretically not so economical as the return flue boiler and compound engine, will hi many cases prove so practically because they are so much simpler and there is not the chance to go wrong with them that there is with the others. If for any reason you want a very quick steamer, buy an upright. If economy of fuel is very important and you are prepared to make the necessary effort to secure it, a return flue boiler will be a good investment, and a really good compound engine may be. Where a large plant is to be operated and a high power constant and steady energy is demanded, stick to steam, since the gasoline engines of the larger size have not proved so successful, and are certainly by no means so steady; and in such a case the exhaust steam can be used for heating and for various other purposes that will work the greatest economy. For such a plant choose a horizontal tubular boiler, set in masonry, and a compound engine (the latter if you have a scientific engineer).