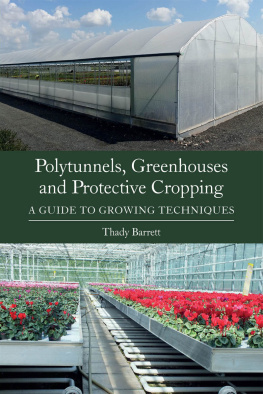

Polytunnels, Greenhouses

and Protective Cropping

Polytunnels, Greenhouses

and Protective Cropping

A GUIDE TO GROWING TECHNIQUES

Thady Barrett

THE CROWOOD PRESS

First published in 2016 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2016

Thady Barrett 2016

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 186 4

Disclaimer

The author and the publisher do not accept any responsibility in any manner whatsoever for any error or omission, or any loss, damage, injury, adverse outcome, or liability of any kind incurred as a result of the use of any of the information contained in this book, or reliance upon it. If in doubt about any aspect of protected horticultural cultivation, growing and cropping, readers are advised to seek professional advice.

Dedication

To George Allen, OBE, director for the Lea Valley Experimental Horticultural Station 19631981, who provided me with the opportunity to witness the development of alternative clad greenhouses for wider use in horticulture. And to the grower/managers who directed my practical experience and education in such a wide range of greenhouse crops (1980 and 1982): Wolfgang Kruger, David Kemp and John Hopkins.

Contents

Preface

As soon as one mentions the word polytunnel it being the first word in the title of this book there are those who conjure up their own images of intensive horticultural cropping in many geographical areas of the world, as do those not directly involved in agriculture. Polytunnels can be seen as a blight on the landscape, while some folk in the industry see them as a cheap alternative for those who do not have the resources to build in glass. There are many misconceptions within the horticultural industry that do not reflect the application of the incredible scientific and technical developments around the world for numerous cladding materials. This aspect in itself continues to evolve to meet the needs of growers tasked with producing the crop qualities demanded by retailers, and the complex schedules necessary to meet continuity of production.

The objective in my mind is to open up the possibilities for many hybrid solutions to meet the varying needs of crops, and the geographical and climatic limitations that can be encountered. For those traditionalists of northern Europe, standard horticultural glass as a cladding material itself is not redundant, but is also evolving to meet energy conservation requirements and light interception properties.

Clearly as soon as any book hits the shelves, some sections are already going to be out of date such is the pace of change, driven by an increasing demand for sustainable food supplies, to the developing economies requiring the more luxury items. The development of LEDs continues to march inextricably forwards, with the euphoria that it can solve many problems if only the price could come down, I hear you say!

Its fair to say that the chapters on structures and cladding materials are somewhat biased towards horticulture at more northerly latitudes; however, there is much to be learnt about composts, irrigation, feeding, and pest and disease control. These are all familiar topics to every geographical location, and solutions found in one locality often cross-fertilize to other regions, for all to benefit.

In compiling the research for this book, I had the opportunity to establish links with many of the research and commercial organizations out there servicing the needs of horticulture. Trade shows play an important part in this, as initial contacts can be made, and remembering a face helps open more doors and brings forward much of the camaraderie that exists in our industry.

Companies large and small, and research organizations, have all strongly supported this endeavour with the provision of technical data, editing descriptions and images, and some have even taken the time to give me guided tours of their own enterprises a truly international spectrum of contributors. I am also grateful to those who have allowed me on to their enterprises to take photographs and to glean their personal experiences and approaches.

There are few books on this topic generally; readers may be aware of a very limited number of standard reference texts that contain significant scientific input and in-depth technical data: I have not sought to compete with these. It is perceived that the primary readers for this level of text will range from the undergraduate student, those in managerial positions within the industry, to owners of small to medium-sized enterprises and across the horticultural cropping spectrum.

Acknowledgements

It is impossible to identify and give thanks to everyone who contributed to this work, but I have endeavoured to ensure that their respective organizations are credited within the text via inclusion of website addresses.

The following have been instrumental in compiling this book:

Glenn Behrman of GreenTech, Hugo Plaisier of Ludvig Svensson, Richard GreatRex and Caroline Reid of Syngenta Bioline, Andrew Wilson and Adam Ferjani of ICL UK & Ireland, Catherine Dawson of Melcourt Industries, Dominic Cahalin of Delt-T Devices, Rudolf Van Looveren of Van Looveren NV, Henry Wainwright of the Real IPM Co, Hugo Paans and Peter Vos of Erfgoed Holding BV, Electra Hatcher of Keder Greenhouses, Krzysztof Hernick of Tomtech, Mike Abel of Agralan, Marianne Nieuwenhuijsen of Asking.nl/InnovatieNetwerk, Ruth Ashfield of Agriculture and Horticulture Development Board, Harel Dotan and Ronit Golovaty of Paskal Technologies, Seiji Matsuda of AGC Chemicals/f-clean, John Downey of Act Publishing, Jack Crooker of Ball DPF, Tobias Huni of Birchmeier, Michael Neff of American Society for Horticultural Science, Michelle Keyser of National Greenhouse Manufacturers Association, Walter van Esch of In Greenhouses magazine, Michael Seifert of Moeschle, Andy Barber and Aaron McIvor of BPI Visqueen Hort, Amy McCormack of Natures Source Plant Food, Philip Ronn of Argents Nurseries, Chris Batchelor of Wallings Nursery, Robert Farthing of Cornerways Nursery, Mike Smith of WD Smith, Mark Lever of UK Salads, Barry Robertson at John Innes Centre, Andrey Ivanov and Chris Newenham of Wilkins & Sons, Peter Hill of Hill Brothers and Rabbe Ringbom of Valoya.

Greenhouse Design Principles

In North America and in Europe there are standards set out for greenhouse designers, defined by codes to follow that consider the geographical and topographical siting and the proposed use of the project at the design stage. For example, in response to heavy storms and consequent damage in Holland in the 1980s, the ability to adequately insure glasshouses became tested. In response, the industry had to quickly come up with, and adopt, what is now the European standard (EN12021-1) to design, calculate and build in the correct glasshouse structural strength.

Greenhouse designs revolve around calculating loads that are placed on the proposed structure, but will also ensure that the structure has adequate stiffness to limit both vertical and transverse deflections. Lateral forces that consider the wind load on a structure will also cover seismic requirements. Readers wishing to know more can follow the American standards, for example via the National Greenhouse Manufacturers Association (http://www.ngma.com).

Next page