Steve Hole - Build Your Own Kit Car

Here you can read online Steve Hole - Build Your Own Kit Car full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. publisher: Crowood, genre: Detective and thriller. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Build Your Own Kit Car

- Author:

- Publisher:Crowood

- Genre:

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

- 60

- 1

- 2

- 3

- 4

- 5

Build Your Own Kit Car: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Build Your Own Kit Car" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Build Your Own Kit Car — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Build Your Own Kit Car" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

Since the turn of the twentieth century, people in sheds and garages all over the country have been dismantling and rebuilding cars, creating home-brewed specials from all manner of components. The earliest attempts at rebuilds, new builds and odd builds frequently used Austin Sevens, old Ford 8s or even Bentleys as a platform on which to create the car of the builders dreams.

The first inspiration for kit cars in the UK can probably be attributed to a design created by engineer Thomas Hyler-White (18711930), in 1896. It later appeared in a magazine called English Mechanic and World Of Science and Art in January 1900. The series of part-works entitled A Small Car and How to Build it, based on a Benz Velo, appeared in fifty-six instalments.

Interest in self-building unique cars accelerated in Britain after the Second World War, when any new cars that were being produced post-war were destined for export to provide the government with much-needed funds. De-mob happy young men up and down the country were starved of motorsport and petrol was still rationed. Bowed but undaunted, the motoring enthusiast adopted a make do and mend approach and did the best job they could to turn old bangers into objects of desire. Soon, intrepid engineers, many of whom were motorsport participants, came up with a range of solutions to the challenge.

The forerunner of the specials movement, and the man who should be considered as the father of the kit car industry in the UK, was Derek Buckler, who ran an engineering company in Berkshire. When motorsport started to make a re-appearance after the war, Buckler created his own special, which quickly brought him success in hill-climbs and sprints. Before long his car began to attract attention from other drivers, who asked him to create a similar car for them.

Suitably encouraged, Derek Buckler set up his eponymous car company at his base in Reading. In keeping with the somewhat eccentric nature of the early cars, his working practices were known to be unusual; he would not give out the finishing touch of a bonnet badge until he had personally seen and inspected the customers car. He did not supply bodies for the chassis he produced, instead sending customers to his in-house panel beater, giving them a number of proprietary and preferred bodies from which to choose. The panel beater was self-employed and would issue a separate invoice for the work done.

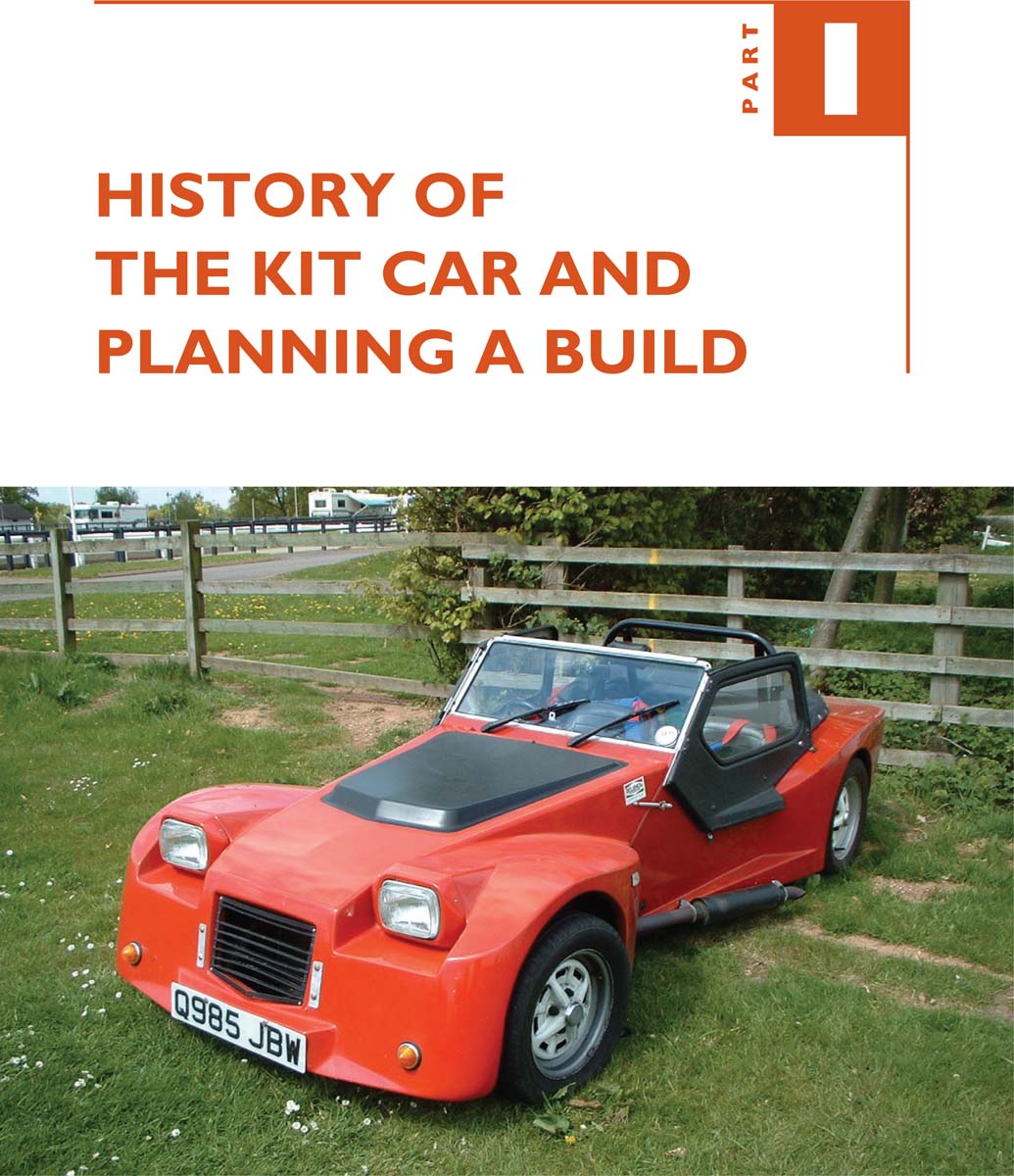

Derek Buckler is widely regarded as the founding father of the UK kit car industry. His MkV (shown here) was not his fifth design, but his first; he chose the designation because he did not want potential customers to think that he was a newcomer. He did not offer bodies for his cars, but pre-glassfibre he had an in-house franchise that could craft a bodyshell for one of his chassis. With the advent of glassfibre he had arrangements with leading shell makers of the day such as Microplas. His bonnet badges were awarded only when he had personally seen a customers car and it had passed muster.

In the early 1950s, a whole string of companies sprang up to satisfy the demands of the specials builder. Glassfibre (also known as GRP, fibreglass, fiberglass, glass reinforced plastic, and glasfaserverstrker kunststoff, among other names) soon emerged as the perfect medium for use for a car body. No other material is more suitable for the production of car bodies in low volume and its introduction was crucial to the advent and development of the kit car industry. Aluminium, which forms part of the more exotic composites such as carbonfibre and Kevlar, is usable, but its use is more labour-intensive and much more expensive.

The advent of glassfibre offered all manner of possibilities to budding new car manufacturers. Soon, many small operations were enticing motorists with swooping, rakish designs, which exploited the fact that glassfibre could be moulded into shapes that were hard to achieve and/or too expensive to produce in aluminium.

Manufacturers in the USA were the world leaders in glassfibre and resin technology, with fibreglass strands and matting first appearing commercially in 1938, through Owens-Corning Fiberglas Corporation of Ohio. DuPont and Cyanamid were among the pioneers of resins in 1942, and the first car with a body made from glassfibre was Bill Tritts Glasspar G2. General Motors was the first manufacturer to showcase a mass-produced glassfibre body, used for its Corvette model at the Detroit Motor Show of January 1953. Another American manufacturer, Kaizer-Frazer, was not far behind, with its Henry J model.

The UK soon caught up, with a company called Microcell exhibiting a one-piece glassfibre body that it had developed for Allard in mid-1953. Singer (SMX Roadster, designed by Bill Tritt) and Jensen (541) were the first UK makers to use the material in mass production, recognizing the importance of this new substance to the car manufacturing industry.

The first glassfibre kit car body for the UK market came from RGS Automobile Components, run by Dick Shattocks. In June 1953 he used it on the re-launched, pre-war Atalanta that his company had acquired. In these early days of glassfibre kit car bodies, results were often patchy as companies had yet to master the art of consistent manufacturing quality. Inevitably, some had more success than others.

Dick Shattocks RGS Automotive was the first specials manufacturer to offer a proprietary commercially available glassfibre bodyshell in the UK, in May 1953. In addition to supplying a range of go-faster goodies, Shattocks had also acquired the defunct pre-war marque, Atalanta. The bodies were made by the snappily titled North East Coast Yacht Building and Engineering Company Ltd.

Next pageFont size:

Interval:

Bookmark:

Similar books «Build Your Own Kit Car»

Look at similar books to Build Your Own Kit Car. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Build Your Own Kit Car and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.