101

KNIFE

DESIGNS

PRACTICAL

KNIVES

FOR DAILY USE

MURRAY CARTER

DISCLAIMER

This book is all about practical knife designs. It is written for the reader who desires first and foremost to make or own a knife that will be held and used for extended periods of time to cut things. This doesnt mean to imply that other types of blades and knives, such as Fantasy or Art knives, have no merit in the cutlery world. Definitely not! Fantasy and Art knives offer richness and variety to the cutlery market, for everyones benefit. As these knives are limited only by the artists imagination and skills, it is exciting to see what will come along next in this exciting arena of knife design.

At the end of the day however, it is the practical knives that will get continual use for meaningful tasks and will become cherished keepsakes of their owners. I believe it is imperative that any aspiring full-time knifemaker offer several practical knives in their repertoire. While it is possible for a select gifted few to make a good living selling only fantasy or art knives, most other knifemakers will survive periods of tough economic times by offering some knives that customers can actually use.

Practical vs. fantasy: After a long day of cutting tasks, which will still be in your hand?

TERMS AND DEFINITIONS

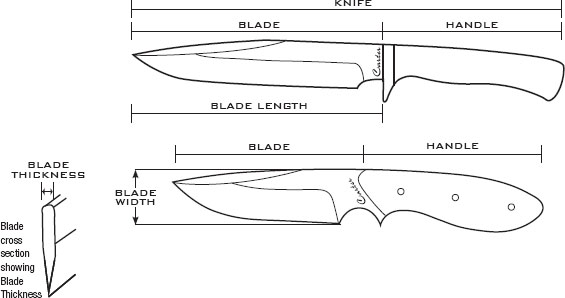

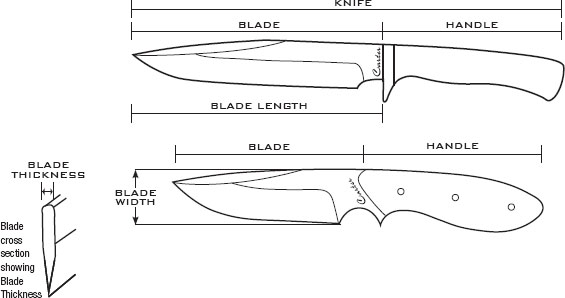

A note on the distinction between the terms blade, handle and knife, and how the terms length, width and thickness apply.

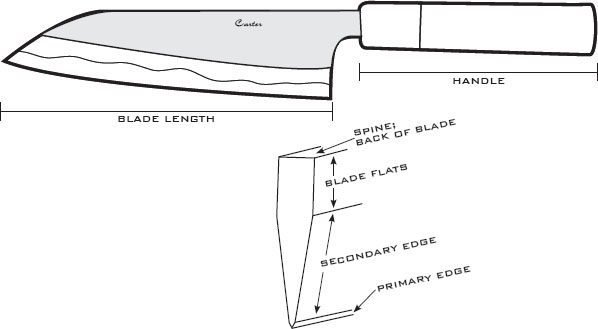

I define a blade as being the part of a knife that slices, chops or pierces as measured from the furthest tip to the beginning of the handle. If a knife has a guard or bolster, that is where the blade begins. If a knife has no guard, the blade begins at the front of the material that constitutes the handle.

The handle is the part of the knife that is held in the hand during regular use. The handle includes the metal guard if the knife has one. The end of the handle is the part of the knife furthest away from the blade tip. A knife is defined as a blade with a handle so as to be held in the hand during use.

The term length when referring to the blade means the dimensions of the blade from tip to the start of the handle. (However, kitchen knife blade length is measured from the heel of the blade to the tip).

Width is the dimension from the spine of the blade to the cutting edge (or cutting edge to cutting edge in the case of a dagger). The terms wide and narrow are used to describe width.

Thickness is the dimension of the fattest part of the blade between the right and left sides. Thickness will always be a smaller dimension than width. Thin, light, thick and heavy are terms used to describe a blades thickness.

Terms Knife, Blade, Handle, Length, Width and Thickness and how they apply to knives. Note that blade length is measured differently on kitchen knives than other knives.

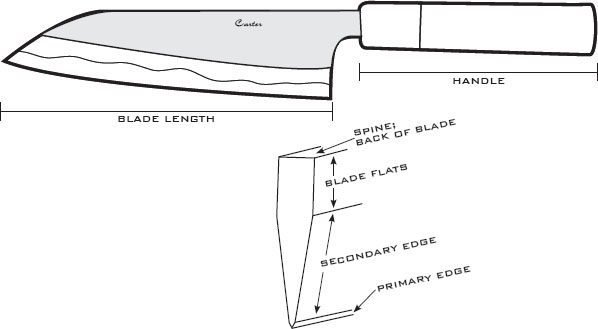

The primary edge on a blade is what first comes in contact with the material being cut. The primary edge initiates the cut. As the blade cuts into the material, the secondary edge becomes a factor as it determines how easily the blade can travel through the material.

Diagram of primary edge, secondary edge, blade flats and spine of a blade.

INTRODUCTION

Like many North American boys, I have been fascinated with knives and things that go cut since my early childhood. As fate would have it, I ended up in Japan at the age of 18 where I fell into an apprenticeship with a 16th generation Yoshimoto bladesmith that lasted six years. Upon completion of that fortunate tutelage, I continued forging blades in Japan for twelve more years, moved to the U.S. in 2005 and have continued forging blades since then. To date I have personally completed over 17,000 knives, the majority of which were one-of-a-kind pieces consistent with the kind of work done by old-world artisans.

Named after my old forge in Japan where I first made this pattern, the Tabaruzaka Utility neck knife is as slick as they come. It features a Hitachi white steel #1/stainless laminate blade, HRC 64, unpolished hammer forged finish and a reverse coffee jelly handle (brown and black micarta).

I am indeed very fortunate to have found paying customers for most of those knives. As it was in the early days of my career, so it remains today a challenge to create knives that are appealing enough for customers to feel the compulsion to part with their hard-earned cash to buy one of my premium blades. I do believe that I have learned a thing or two during that time about appealing knife design. Teaching others at my exclusive Traditional Japanese Bladesmithing School has further refined my convictions on the topic. It has been a double blessing in helping me communicate both the obvious and also the subtleties of the lines of knives.

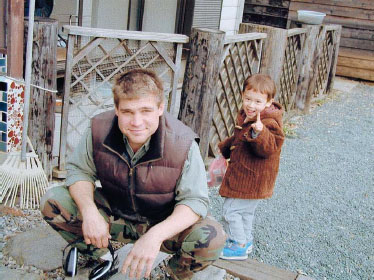

Hand sharpening a combat knife at the Tabaruzaka Forge, Kumamoto, Japan, 2002.

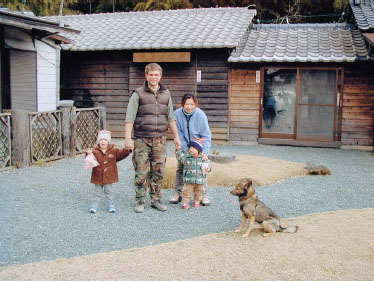

Carter Family in front of the Tabaruzaka Forge in 2001.

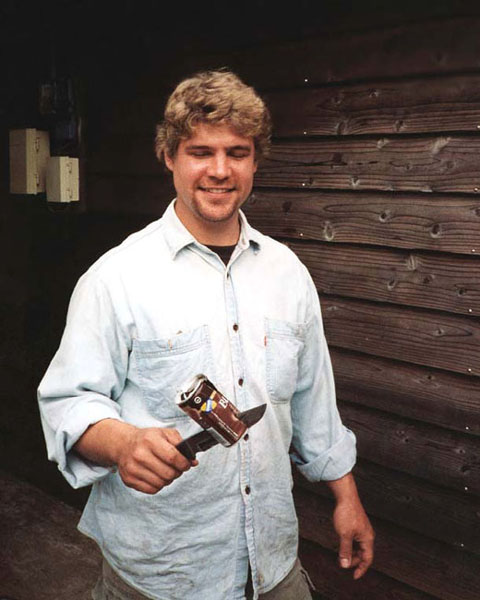

17th Generation Yoshimoto Bladesmith Murray Carter. Who will be the 18th?

I invite you now to join with me as I explore the successful common traits in popular knife design that have lasted throughout all of mans history. Both enthusiast and maker alike will learn how to identify the common traits in great knives, and the latter will better understand how to apply them to new knife design.

It can be said that knives are task-specific tools with only three objectives: to slice, chop or pierce.

Slicing is moving a relatively thin blade through the subject matter in a perpendicular fore or aft drawing motion. A relatively long section of the blade comes into contact with the same area of the subject matter as the blade is drawn through perpendicularly. The doctors use of a scalpel during surgery or removal of a thin slice of beef from a roast are two examples of slicing.

Almost all the way through a stiff Japanese coffee can. These cans are as thick as the old apple juice cans from the 1970s.