INTRODUCTION

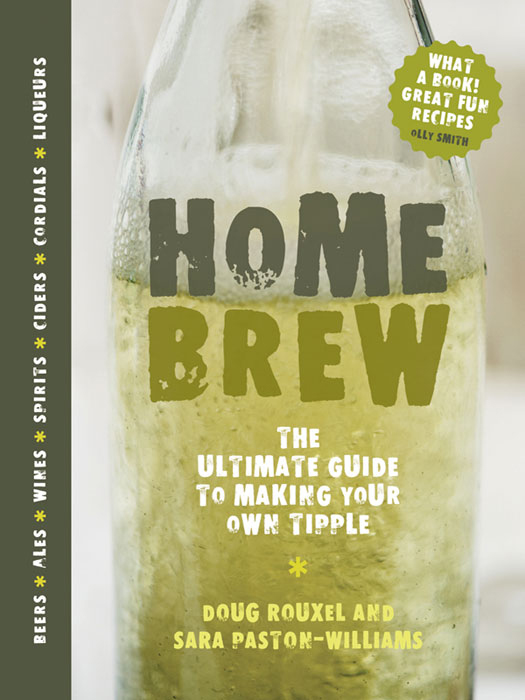

Whether you have a glut of produce on the allotment, an abundance of apples on your apple tree or simply a burning desire to create your own brew, Home Brew is the much needed, one-stop guide to everything you need to know about making your own drinks. Avoid the disasters, the exploding bottles in the airing cupboard, the ever-so-slightly flat brews, the over-sweetened sloe gins, and take advantage of our collection of tried and tested recipes that will impress even the most discerning drinker.

The recipes come with variations set to inspire you, information on how to get started and also a comprehensive guide to all the skills, techniques and processes involved in making your own brew. Armed with this knowledge, the world of fruit wines, beers, ciders, spirits and cordials is really at your fingertips.

Have fun creating brews for many occasions. Fruity cordials make a thirst-quenching offering for a barbecue, light and refreshing elderflower or lavender champagnes add a special touch to any celebration, and a bottle of sloe gin or quince brandy can solve your Christmas present conundrums.

This resource is not meant to be precious, so weve already stained the pages for you! Be free, feel inspired and enjoy making your own tipple without boundaries.

Cheers!

PART ONE

GETTING

STARTED

THE BASICS

Understanding the basics

How are alcoholic drinks made?

Dealing with fungi and bacteria

Extracting sugars

Fermentation

Racking

Conditioning

Storage

General equipment

MAKING FRUIT WINES AND SPIRITS

The basic principles

The ingredients

Flavouring

Water

Sugar

Yeast

Other essentials

Winemaking

Initial preparation of the must

Preparing the must for fermentation

Fermentation of the must

Maturation of the wine

What to do if fermentation is stuck

MAKING BEERS, ALES AND CIDERS

The roots of beer

Equipment for beer-making

Mash tuns

Boilers

Cooling equipment

Storage equipment

Ingredients for beer-making

Base malts

Malt extracts

Speciality malts

Hops

Water

Yeast

Making a yeast starter

Ways of making beer

Beer kits

Extract brewing

Full-mash brewing

Understanding the beer recipes

Cider, perry and mead

Equipment for cider making

Scratter or pulper

Pressing

Ingredients for cider making

Cider apples

Perry pears

Mead ingredients

Making cider and perry

Making mead

THE BASICS

all you need to know

UNDERSTANDING THE BASICS

HOW ARE ALCOHOLIC DRINKS MADE?

This chapter is about the basic principles of making many kinds of alcoholic drinks. It covers the essential areas that are common to all of them, no matter which drink specifically interests you. It takes you through the preparation needed, explains how the sugars are obtained, how the process of fermentation works and how long it takes for this to become something drinkable.

The terms brew and brewing are often used, which might seem slightly beer-centric. Its not intended to be: there just isnt a better catch-all term.

DEALING WITH FUNGI AND BACTERIA

The central process to home brewing or, in fact, any brewing is fermentation. This promotes the growth of yeast, a fungus, in order for it to work through its lifecycle in our brew, so that we end up with an alcoholic drink. Creating ideal conditions for a fungus to thrive, though, means that we are making conditions that will enable many other fungi and bacteria to thrive too. So keeping things clean and sanitary is of paramount importance.

In order that our desired fungus (the brewing yeast) has the greatest chance to gain full control of our brew, and that unwanted micro-organisms (wild yeasts or vinegar bacteria, for example) have little or no chance of procreation, we must ensure that things are not only clean but also sterilized.

Within home brewing terminology, sterilizing is the term most often used. However, it is not strictly a sterilizing process: we do not want to kill all bacteria; we just want to ensure that our bacteria has the best chance of surviving. Sanitizing would possibly be a better term, but sterilizing is widely accepted and understood.

CLEANING

All equipment used in the brewing process must be cleaned and, as much as possible, all marks and discolouration removed. Household detergents such as washing-up liquid can be used, but more stubborn stains may require the use of soda crystals. Glass is easy to clean and does not stain readily, which made it the mainstay of home brewing for many years. The expense of large glass vessels has seen its popularity decrease in favour of food-grade plastic, but these are more difficult to keep clean. Some shapes of container are more difficult to clean (bottles and demi-johns, for example) and may require a specially shaped brush to reach the corners. These can be obtained from good home-brewing suppliers.

Once all the items in the brewing process have been cleaned, they must be fully rinsed. This is to ensure that all residues of detergent are removed. Detergents in the finished products may spoil the taste. They affect beer in particular, altering the surface tension of the beer, meaning that it will not maintain a head.

STERILIZATION

All equipment that comes into contact with the brew prior to or following the fermentation process requires sterilizing. If there is any lengthy boiling that takes place in the brewing process (for full-mash beers, for example), anything that comes into contact before the boil must be clean but does not require sterilizing. Anything that comes into contact with the brew after the boil will, of course, require sterilizing.

The main sterilizing solutions used in home brewing are chlorine-based. The easiest way to ensure the correct volume and strength of solution is to use one of the many home-brewing cleaning and sterilizing solutions available from any home brew supplier.

It is possible to use simple household bleach, calculating the volume to create a solution of an appropriate strength, but this is not an approach we would recommend for a beginner.

Sterilization is also important in winemaking. Airborne yeasts and vinegar bacteria can only be kept at bay by constant vigilance. Sulphite is described as the winemakers best friend. This is most commonly available in the form of Campden tablets, but can also be bought as a crystalline powder called sodium or potassium metabisulphite.

Make a solution of one Campden tablet, a few grains of citric acid and 600ml/1 pint/2 cups cold water. Use to rinse all your equipment, before and after use, to sterilize it.

This has the advantage of being a solution that is less likely to taint the flavour of the final drink. However, the level of sanitization it offers is below that of the modern chlorine-based cleaners and, as such, it has fallen from favour with home brewers.