Table of Contents

ACKNOWLEDGMENTS

I would like to thank the folks at Hypertherm for their support over the years. They have gone to great lengths to extend personnel training, as well as loan us equipment for shows and special projects. Their machines have performed flawlessly through countless projects, many of them in very challenging conditions.

DEDICATION

To my wife, Renee, and daughter, Ariel, for all of their support and for allowing me to spend so many hours working and writing these books.

FOREWORD

I met Eddie Paul a few years ago through a mutual friend, and found that he is not just another Hollywood guy, but a true car guy that works in Hollywood. He also loves building life-size cars like in the animated movie Cars, motorcycles, and even an occasional mechanical shark. I also discovered he has a knack for writing technical how-to books. Since that first day, we have crossed paths many times at car shows and events. He has been to my shop, Big Dog Garage, and Ive been to his to compare notes, and hes offered a lot of advice over the years with my car collection.

When he asked me to write a foreword for his plasma book, I discovered that we had the same Hypertherm units. I asked him to come down to my shop and show me some of his tips on plasma cutting. A lot of those tips are in this book. So, while Eddie is still a much better car builder, I can now cut cars up just as well as he can!

Jay Leno

INTRODUCTION

When I was a kid, there were only a few books that dealt specifically with the craft of metalworking. I learned most of what I know from my dad, who built everything from cars, motorcycles, and machinery to boats and custom aircraft. When I was twelve years old, I asked him for a mini-bike. He replied that if I really wanted one, hed show me how to build my own. That way Id appreciate the bike so much more than if he bought or built me one himself.

Well, he was right. My excitement gave way to misery as I spent hours cutting the steel to shape with a heavy oxyacetylene torch. Then I spent more hours grinding metal with a 40-lb electric disc grinder to the finished shape. I also remember hours of arc welding metal, and getting countless burns. But that experience set me on a career path building a wide range of custom motorcycles and vehicles for the film and television industry, as well as many corporate and private clients.

After building my mini-bike, I read everything I could find on metal, from the foundry to the different ways of forming and shaping it into useful components. But as I mentioned, there was very little printed information available at the time.

So I learned largely through trial and error. I quickly learned that doing something the wrong way can be painful, both in the wallet and physically. I have more than few scars as reminders. But I also learned a great deal about how to buy equipment, when to bargain hunt, and when to pay a premium. Like so many other things, you do get what you pay for when it comes to tools.

It was also during these years that I learned most of the ways to bend, shape, and form metal, as well as how to anneal and harden steel, which was fairly easy compared to the simple cutting of the metal to shape. This was the part that most fabricators disliked the most but was an important part of fabrication when working in metal. The act of cutting a hole near the center of a piece of sheet metal is not as simple as it appears to be, requiring a lot of tools and skillin most cases, it will warp the metal. A long, straight cut was a challenge for even the most skilled metalworker, as it was for generations, until the advent of the plasma cutter.

I first used a plasma cutter on a large project near the beginning of my film career, when I was working on a pilot for a TV show called Remo Williams. The producers needed a robot and part of it required a bunch of holes cut in the tubular arms.

These are the first two plasma cutters I purchased. They are still working, and are used daily in my shop.

It did not take me very long to realize the potential of the plasma cutter. I could use it for chopping tops, cutting sunroofs, flaring fenders, and almost everything else I needed cut around the shop. Over the years, my plasma cutting machines, particularly the CNC versions, have become indispensable around my shop, and they have paid for themselves many, many times over. With my plasma cutters, I am constantly making custom tools, even if just for one-time use. I now make my own sprockets, simple gears, gussets, brackets, and braces. With my CNC plasma cutter, I can even make right-angle triangles for squaring parts during welding. To be honest, Im not sure Id have been as successful in my business without a plasma cutter.

Chapter 1

Plasma: What It Is and What It Can Do

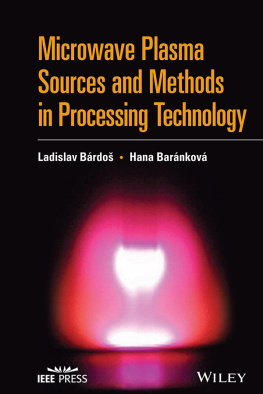

The sun is a ball of plasma and this illustration shows the makeup of this small star.

Plasma: Natures Light

Plasma literally exists in nature everywhere around us. Below is a list of some of the more common areas, uses, and applications where plasma can be found or is encountered everywhere as a part of daily life.

StarsA star is basically a tightly packed ball of plasma held together by its own gravity. The light is the byproduct of the heat created by the energy.

AurorasAlso known as the Northern Lights or the Southern Lights, auroras are light displays in the sky; they originate when solar wind (which is a stream of charged particles from the sun) interacts with the strong, fluctuating magnetic field surrounding the earth. The collision impacts gas molecules high in the atmosphere, changing color and shape in milliseconds and producing a spectacular light show.

LightningA few hundred million volts of electricity form into a discharge large spark which occurs when the number of free electrons and ions in the air rises rapidly, causing the air to become an electrical conductor. Lightning is the best example of a natural spark. Some lightning bolts can be many miles in length. Discharges of static electricity are another naturally occurring spark but obviously on a much smaller scale.

Neon LightsA neon light consists of an electric current being conducted through a vacuum tube containing neon gas. The excited gas that glows orange-red is plasma.

Fluorescent BulbsBulbs with an electrical current that flows from the ballast through the gas, causing it to emit ultraviolet light, which then excites a phosphor coating on the inside of the tube. The coating emits the visible light that we see.

Plasma TelevisionsTwo plates of glass have many millions of noble gas cells sandwiched between them. Embedded electrodes can cause gas in individual cells to ionize, once again forming plasma. UV light emitted by the small plasma cell excites a phosphor coating, which then glows in a controlled combination of reds, greens, and blues to produce a television picture.