Adlard Coles Nautical An imprint of Bloomsbury Publishing Plc 50 Bedford Square, London, WC1B 3DP, UK - 1385 Broadway, New York, NY 10018, USA www.bloomsbury.com This electronic edition published in 2016 by Bloomsbury Publishing Plc ADLARD COLES, ADLARD COLES NAUTICAL and the Buoy logo are trademarks of Bloomsbury Publishing Plc First published 2014 This electronic edition published in 2016 by Uitgeverij Hollandia BV, Postbus 317, 2000 AH Haarlem, Netherlands

Adlard Coles Nautical An imprint of Bloomsbury Publishing Plc 50 Bedford Square, London, WC1B 3DP, UK - 1385 Broadway, New York, NY 10018, USA www.bloomsbury.com This electronic edition published in 2016 by Bloomsbury Publishing Plc ADLARD COLES, ADLARD COLES NAUTICAL and the Buoy logo are trademarks of Bloomsbury Publishing Plc First published 2014 This electronic edition published in 2016 by Uitgeverij Hollandia BV, Postbus 317, 2000 AH Haarlem, Netherlands

First published in English 2016 Jan-Willem Polman & Manja Thiry Jan-Willem Polman & Manja Thiry have asserted their rights under the Copyright, Designs and Patents

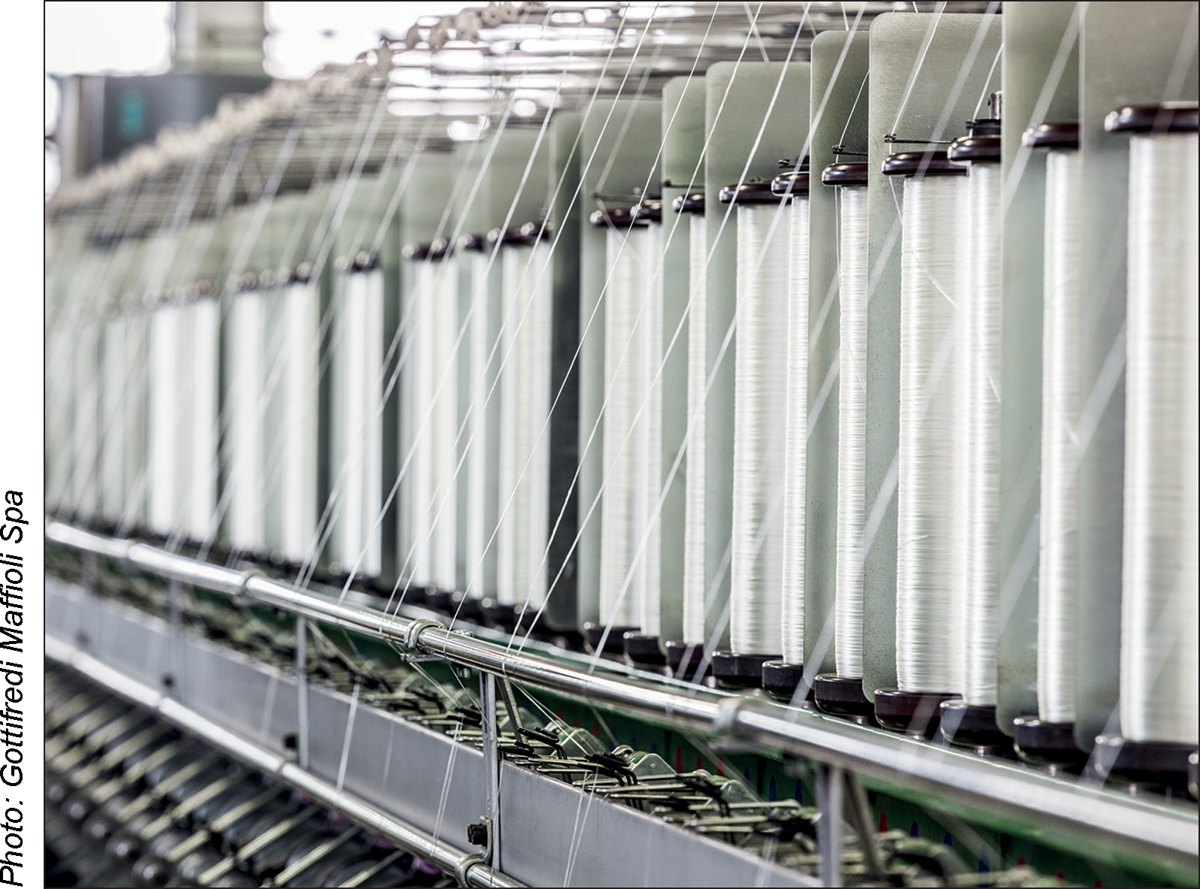

Act, 1988, to be identified as Authors of this work. Photographs: Jan-Willem Polman, except p10 & p16 ( Gottifredi Maffioli Spa) and p25 ( Spinlock) Dyneema is a registered trademark of DSM IP Assets B.V. L.L.C. All rights reserved

You may not copy, distribute, transmit, reproduce or otherwise make available this publication (or any part of it) in any form, or by any means (including without limitation electronic, digital, optical, mechanical, photocopying, printing, recording or otherwise), without the prior written permission of the publisher. Any person who does any unauthorised act in relation to this publication may be liable to criminal prosecution and civil claims for damages. No responsibility for loss caused to any individual or organization acting on or refraining from action as a result of the material in this publication can be accepted by Bloomsbury or the author.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library. Library of Congress Cataloguing-in-Publication data has been applied for. ISBN: HB: 978-1-4729-2320-2 ePDF: 978-1-4729-2492-6 ePub: 978-1-4729-2491-9 2 4 6 8 10 9 7 5 3 1 Bloomsbury Publishing Plc makes every effort to ensure that the papers used in the manufacture of our books are natural, recyclable products made from wood grown in well-managed forests. Our manufacturing processes conform to the environmental regulations of the country of origin. To find out more about our authors and books visit www.bloomsbury.com. BRAND NAMES USEDCordura is a registered brand of Invista www.invista.comDacron is a registered brand of Invista www.invista.comDiolen is a registered brand of FR Safety Yarns www.frsafety.deD-Splicer is a registered brand of D-Splicer B.V. www.d-splicer.comDyneema is a registered brand of DSM Dyneema B.V. www.Dyneema.comKevlar is a registered brand of E. I. I.

DuPont de Nemours and Company www.dupont.comMarlowbraid is a registered brand of Marlow Ropes Ltd www.marlowropes.comSelma is a registered brand of Selma AS www.selma.noSpectra is a registered brand of Honeywell International Inc. www.honeywell-advancedfibersandcomposites.comSwiftcord is a registered brand of Gottifredi Maffioli Spa www.gottifredimaffioli.comTechnora is a registered brand of Teijin Techno Products Ltd www.teijinaramid.comVectran is a registered brand of Kuraray America Inc. www.vectranfiber.comZylon is a registered brand of Toyobo Co Ltd. www.toyobo-global.comINTRODUCTION An eye splice in braided ropes is often left to a rigger or chandler or the rope is simply knotted. However, not only is splicing a fun thing to do, but most of the techniques are quite easy to learn.  The most important reason for learning how to splice is that you will get much more from your materials.

The most important reason for learning how to splice is that you will get much more from your materials.

A knot can reduce the tractive power of a rope by as much as 50%, whereas a well-spliced rope reduces strength by only around 510%. You can also adapt your splicing to meet whatever needs you have on board, and splice a rope to make your setup easier, safer or faster. If youre a competition sailor the techniques youll learn in this book will optimise your deck layout and save weight on board. Its quite easy to replace much of the steel wire you carry on board with Dyneema, and techniques such as tapering a rope can save weight. Why not splice an extra cover for a better grip in clutches or to extend the lifespan of your rope? There are all kinds of techniques in this book and youll soon see that their uses are pretty much boundless. The first part of this book describes various materials and how to use them on board.

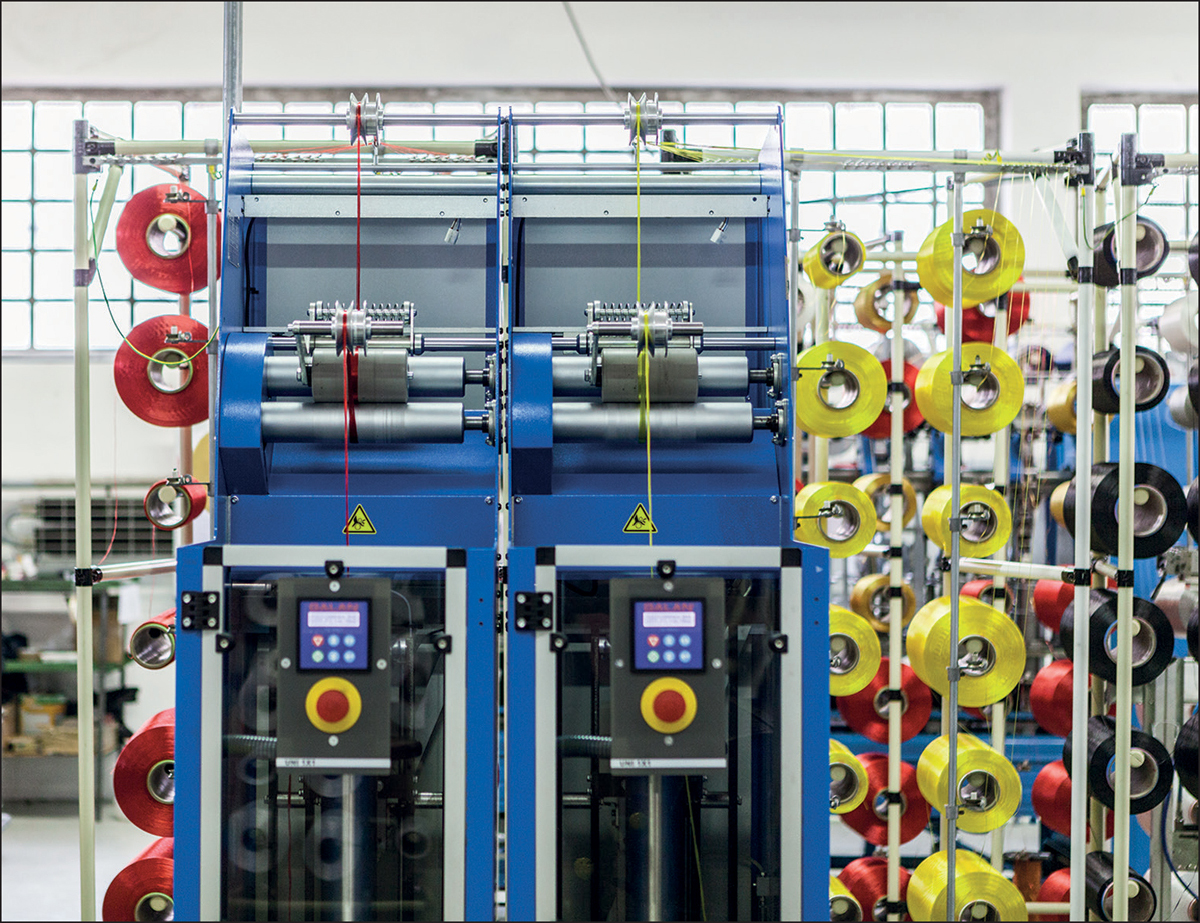

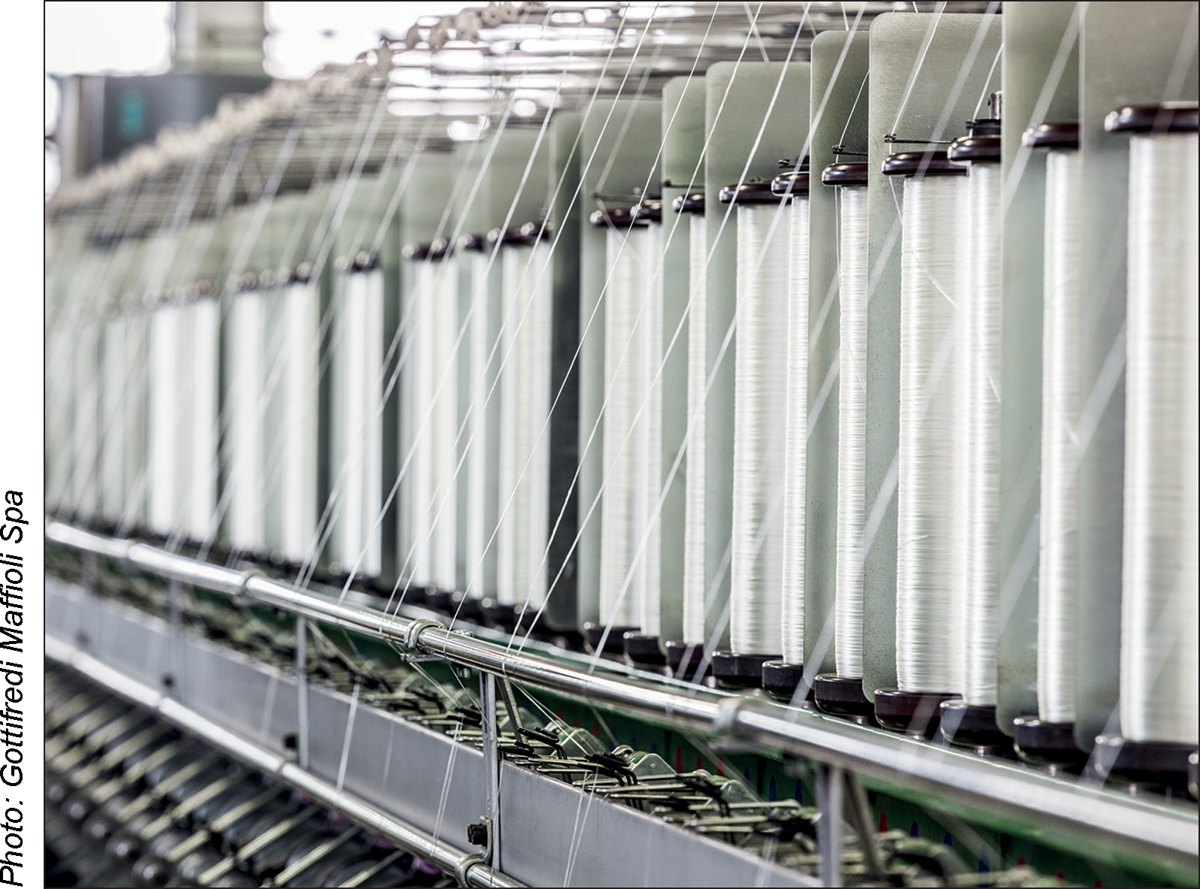

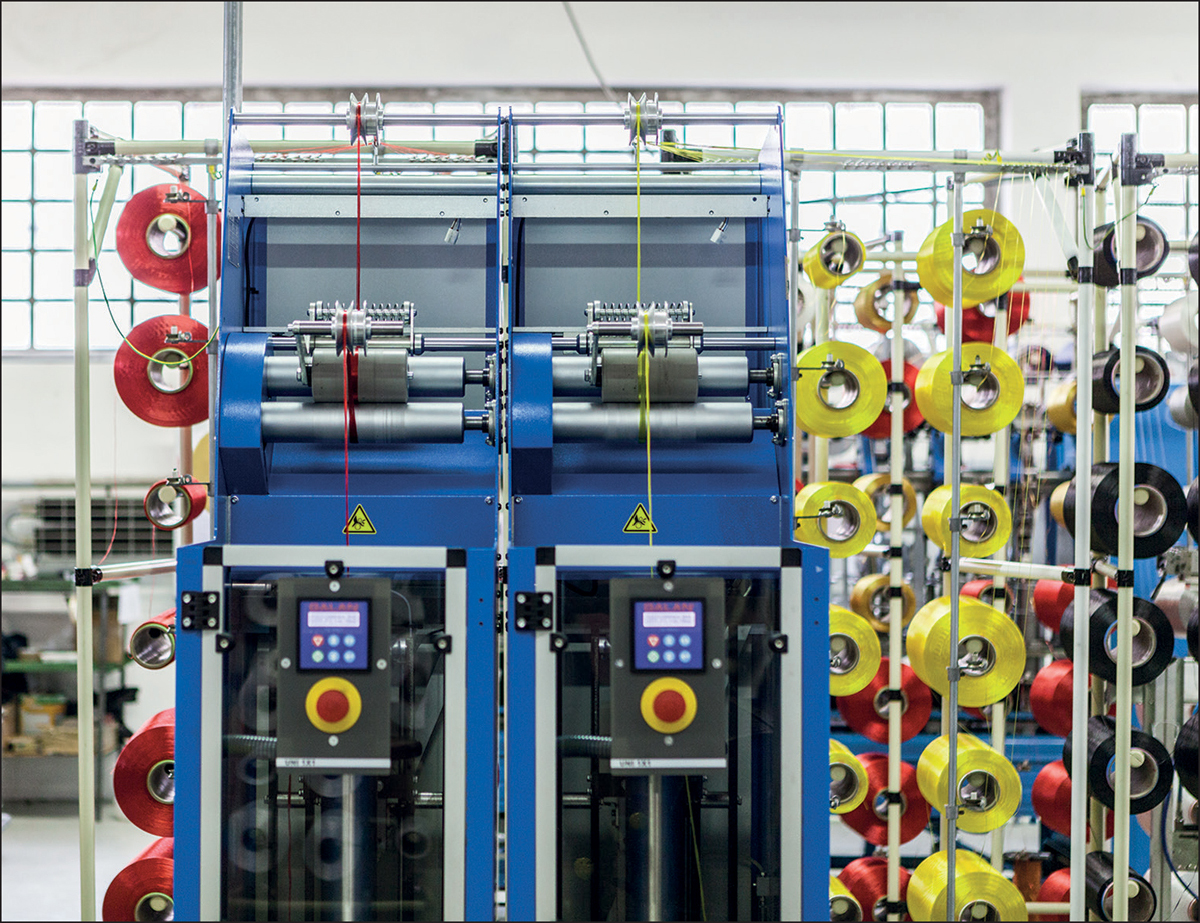

This insight will help you make a selection when buying new ropes. There is no real need to read these chapters first, but before you start splicing be sure to read the general instructions in . Otherwise, start anywhere and consult this book in any way you like.  1 SYNTHETIC FIBRESDEVELOPMENTS In modern rope production, synthetic fibres have quickly come to replace natural fibres such as hemp and flax. These days its rare to see anything on board other than synthetic ropes. Its no wonder, really, as synthetics have many advantages and have been developed very rapidly since the discovery that they could be produced from crude oil.

1 SYNTHETIC FIBRESDEVELOPMENTS In modern rope production, synthetic fibres have quickly come to replace natural fibres such as hemp and flax. These days its rare to see anything on board other than synthetic ropes. Its no wonder, really, as synthetics have many advantages and have been developed very rapidly since the discovery that they could be produced from crude oil.

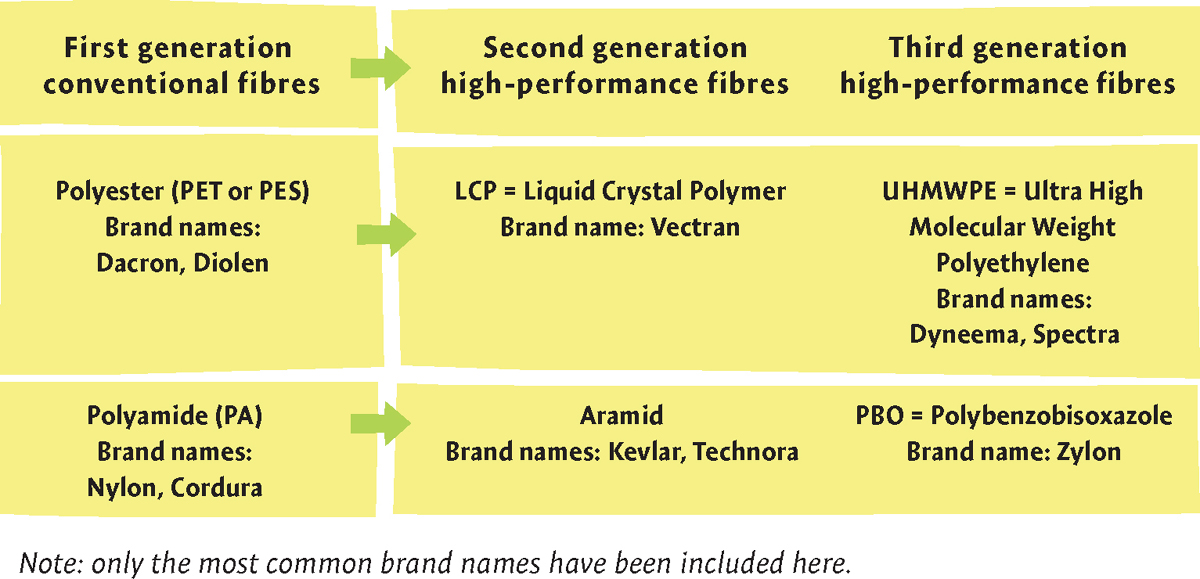

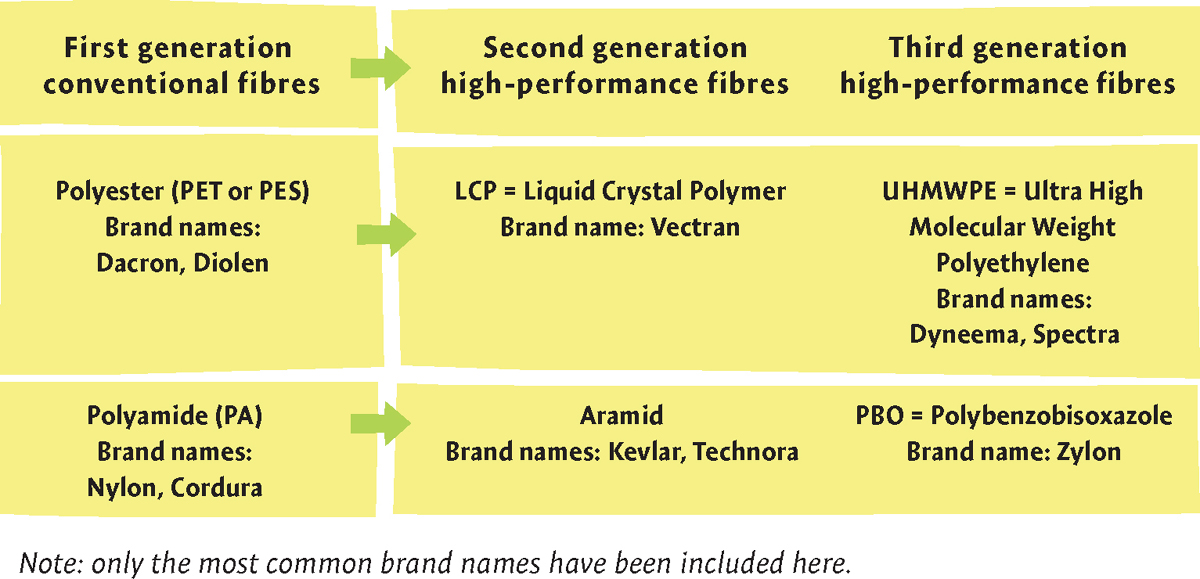

In 1938 DuPont discovered nylon fibre, the first polyester was developed in 1941 and in early 1979 DSM applied for the patent for Dyneema. It can be hard to make sense of the many chemical names for synthetic fibres (which are often indicated in the brand name), but its well worth knowing something about the materials involved before you buy ropes. Polyester and polyamide belong to the first generation of synthetic fibres and are still used for making rope. The second generation, the so-called high-performance fibres, stem from these: LCP (Vectran) comes from polyester, and various aramid fibres (eg Kevlar, Twaron and Technora) are made from polyester or polyamide. The newest generation of fibres includes UHMWPE (Dyneema, Spectra) and PBO (Zylon). MATERIALS BY GENERATION There is still a great deal of work going on to further improve synthetic fibres.

There is still a great deal of work going on to further improve synthetic fibres.

Every material has its advantages as well as its disadvantages, making each suitable for a variety of uses. The most important differences are breaking load, wear, heat/UV resistance and stretch (see ) TECHNICAL FEATURESBreaking load The breaking load is the maximum direct force that a rope can take before it breaks. The breaking load of a rope is expressed in decanewton (daN) or kilonewton (kN) or kilogram (kg). One manufacturer will have a greater safety margin in terms of breaking load than the other; which is why you should use these numbers only as an indication. Safe working load The safe working load (SWL) of a rope is the recommended limit on the strain a rope is subjected to. Generally, around 25% of the breaking load is used as a safe working load.

In practice, however, sails are usually reefed or the boat is in a safe harbour before a rope is loaded to its maximum. Stretch The stretch of a rope is often expressed as a percentage, measured to a particular load (for example, x percent of the breaking load). The more a rope is loaded, the more stretch it will have. When youre comparing stretch in ropes, make sure that the numbers relate to the same degree of load. Stretch properties are determined by a ropes material and construction; for example, the way it is braided affects stretch.

Next page

Adlard Coles Nautical An imprint of Bloomsbury Publishing Plc 50 Bedford Square, London, WC1B 3DP, UK - 1385 Broadway, New York, NY 10018, USA www.bloomsbury.com This electronic edition published in 2016 by Bloomsbury Publishing Plc ADLARD COLES, ADLARD COLES NAUTICAL and the Buoy logo are trademarks of Bloomsbury Publishing Plc First published 2014 This electronic edition published in 2016 by Uitgeverij Hollandia BV, Postbus 317, 2000 AH Haarlem, Netherlands

Adlard Coles Nautical An imprint of Bloomsbury Publishing Plc 50 Bedford Square, London, WC1B 3DP, UK - 1385 Broadway, New York, NY 10018, USA www.bloomsbury.com This electronic edition published in 2016 by Bloomsbury Publishing Plc ADLARD COLES, ADLARD COLES NAUTICAL and the Buoy logo are trademarks of Bloomsbury Publishing Plc First published 2014 This electronic edition published in 2016 by Uitgeverij Hollandia BV, Postbus 317, 2000 AH Haarlem, Netherlands The most important reason for learning how to splice is that you will get much more from your materials.

The most important reason for learning how to splice is that you will get much more from your materials. 1 SYNTHETIC FIBRESDEVELOPMENTS In modern rope production, synthetic fibres have quickly come to replace natural fibres such as hemp and flax. These days its rare to see anything on board other than synthetic ropes. Its no wonder, really, as synthetics have many advantages and have been developed very rapidly since the discovery that they could be produced from crude oil.

1 SYNTHETIC FIBRESDEVELOPMENTS In modern rope production, synthetic fibres have quickly come to replace natural fibres such as hemp and flax. These days its rare to see anything on board other than synthetic ropes. Its no wonder, really, as synthetics have many advantages and have been developed very rapidly since the discovery that they could be produced from crude oil. There is still a great deal of work going on to further improve synthetic fibres.

There is still a great deal of work going on to further improve synthetic fibres.