Copyright 2017 by The Institute of Electrical and Electronics Engineers, Inc.

Published by John Wiley & Sons, Inc., Hoboken, New Jersey. All rights reserved

Published simultaneously in Canada

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per-copy fee to the Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 750-4470, or on the web at www.copyright.com. Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748-6011, fax (201) 748-6008, or online at http://www.wiley.com/go/permission.

Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts in preparing this book, they make no representations or warranties with respect to the accuracy or completeness of the contents of this book and specifically disclaim any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives or written sales materials. The advice and strategies contained herein may not be suitable for your situation. You should consult with a professional where appropriate. Neither the publisher nor author shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

For general information on our other products and services or for technical support, please contact our Customer Care Department within the United States at (800) 762-2974, outside the United States at (317) 572-3993 or fax (317) 572-4002.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic formats. For more information about Wiley products, visit our web site at www.wiley.com.

Library of Congress Cataloging-in-Publication Data is available.

ISBN: 978-1-119-23800-3

Dedicated to the memory of

Professor Joseph Peter Skala

Adjunct Professor at USF and St. Petersburg Junior College

for your support and encouragement to your many students.

Contents

Guide

Pages

LIST OF FIGURES

- Appendix A-1 Application of 1910.269 and 1910 Subpart S to Electrical Installations.

- Appendix A-2 Application of 1910.269 and 1910 Subpart S to Electrical Safety-Related Work Practices.

- Safety clearance to electric supply station fences.

- Photo of load termination compartment in typical medium voltage switchgear.

- Photo of typical shock protection PPE.

- Photo of typical arc flash protection PPE.

- Typical insulated tools.

- Decision matrix if a task requires arc flash PPE.

- NFPA 497 Table 5.9.2 (a) Leakage located outdoors, at grade. The material being handled could be a flammable liquid, a liquefied or compressed flammable gas, or a flammable cryogenic liquid.

- Figure 4.8(a) from NFPA 499 Group F or Group G Dust Indoor, Unrestricted Area; Open or Semi-Enclosed Operating Equipment.

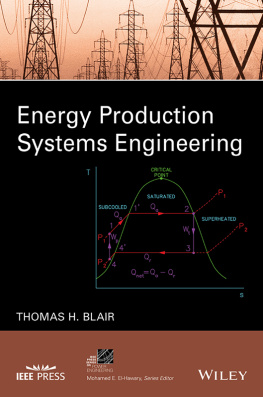

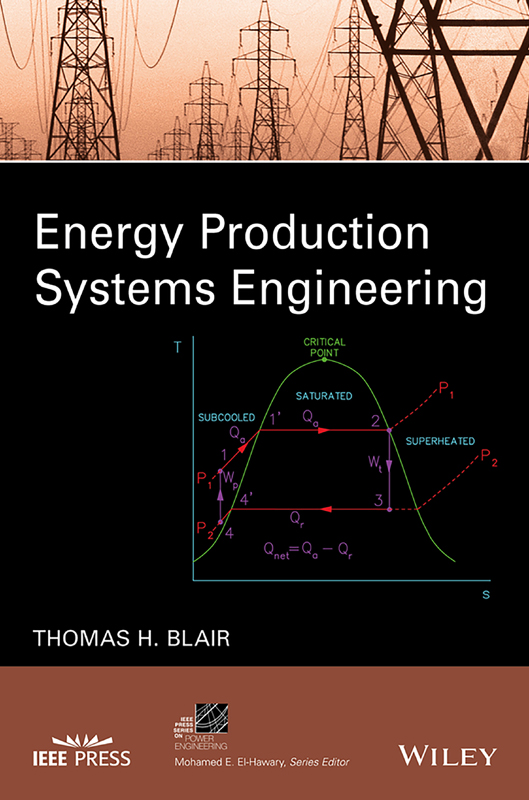

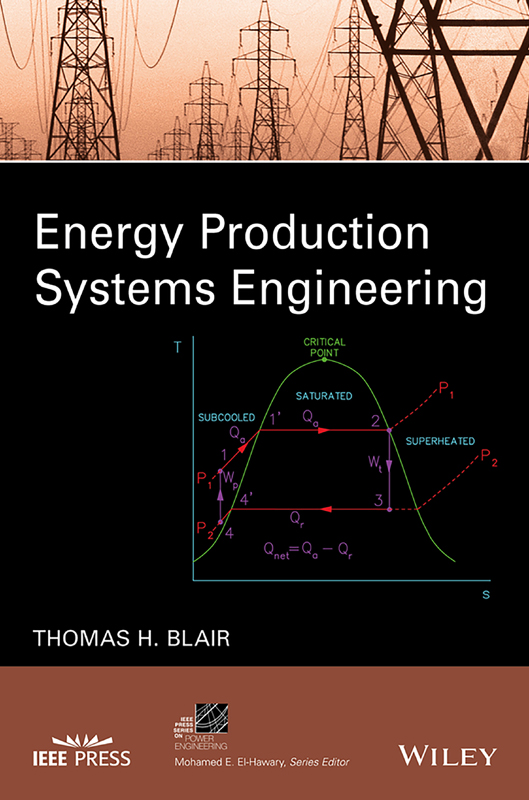

- T-s diagram for water.

- Basic flow diagram for equipment thermodynamic performance evaluation.

- Basic thermodynamic cycle.

- Basic Carnot cycle.

- Basic Rankine cycle showing operation in subcooled region for pumps.

- Feedwater regenerative cycle.

- Feedwater regenerative T-s diagram.

- Superheat design.

- Feedwater regenerative cycle with reheat.

- Feedwater regenerative cycle with reheat T-s diagram.

- Typical steam turbine thermodynamic cycle equipment

- T-Diagram for isentropic Brayton cycle.

- Brayton cycle.

- T-s Diagram for isentropic and non-isentropic Brayton cycle.

- Typical feedwater heater arrangement.

- DCA temperature vs. shell liquid level.

- Basic steam flow path.

- Typical temperature profile for a heat recovery steam generator (HRSG).

- Reduction of boiler efficiency due to excess air.

- Photo of burner front area with boiler wall removed and water wall tubes exposed.

- Secondary air damper before installation.

- Tangentially fired furnace.

- Coal dryer/crusher.

- Ball mill coal pulverizer.

- Coal classifier.

- Vertical spindle coal mill arrangement.

- Vertical spindle coal mill roll assembly.

- Chart of dry bulb temperature to wet bulb temperature

- Fire triangle.

- Estimated US energy usage for 2013.

- Integrated gasification combined cycle (IGCC) process.

- Typical kinetic energy conversion devices.

- Radioactive decay in terms of half-life.

- Typical boiling water reactor (BWR) arrangement.

- Typical pressurized water reactor (PWR) arrangement.

- Reactor emergency core cooling system.

- Reactor post-accident heat removal system.

- Reactor post-accident radioactivity removal system.

- Simplified belt conveyor arrangement with different diameters.

- Simplified belt conveyor arrangement with same diameters.

- Typical tripper arrangement.

- Types of centrifugal fan blade designs.

- Chart showing fan system curve for three system resistance values that depend on damper position with constant fan speed.

- Power for operating points A, B, and C.

- Chart showing fan system curve for three fan speeds with constant system resistance utilizing fan speed for control.

- Power for operating points A, D, and E.

- Pump system resistance with zero differential head and no throttling.

- Pump system resistance with zero differential head and throttling.

- Pump system resistance with non-zero differential head and throttling.

- Pump system operating point.

- Pump flow control utilizing pump speed.

- Pump flow control utilizing throttling.

- Pump flow control utilizing pump speed.

- Pump flow control energy savings.

- Pump monitoring configuration.

- Pump monitoring configuration.

- Typical centrifugal pump.

- Typical rotary screw positive displacement pump.

- Typical condenser arrangement.

- Typical condenser arrangement.

- Two-stage air ejector system.

- Steam turbine gland steam seal system.

- Typical steam turbine equipment.

- Impulse stage pressure and velocity response.

- Velocity compounded impulse stage.

- Pressure compounded stage.

- Reaction stage pressure and speed response.

- Rankine thermodynamic cycle.

- Location of stop (or Throttle) valves and control (or governor) valves and concept of partial arc admission.

- Simplified steam turbine valve arrangement.

- High pressure (HP) steam turbine side view.

- Turbine front standard.

- Radial bearing numbering arrangement for turbine generator.

- Radial shaft seals.

- General machinery vibration severity chart.

- Combustion turbine: compressor rotor assembly.

- Combustion turbine: typical combustor assembly.

- Combustion turbine: typical combustor arrangement.

- Combustion turbine: turbine rotor assembly.

- Combustion turbine: turbine casing assembly showing cooling air.

- Combustion turbine: complete turbine assembly.

- Typical flow diagram for combined cycle power plant.

Next page