Thank you for purchasing this Gun Digest eBook.

Sign up for our newsletter and receive special offers, access to free content, and information on the latest new releases and must-have firearms resources! Plus, receive a coupon code to use on your first purchase from GunDigestStore.com for signing up.

or visit us online to sign up at

http://gundigest.com/ebook-promo

About Contributor David Bradshaw

Throughout this book, youre going to see quite a bit of writing and input from one David Bradshaw. So, just who is David Bradshaw?

David was born in Manhattan, but raised in Washington, D.C., and Old Greenwich, Connecticut. Trained in NRA junior riflery and High Power rifle, he was certified at 16 as a Master with the M1 Garand. He attended art school in Hartford, where he was exposed to the early Colts revolvers at the Wadsworth Atheneum, and Samuel Colt masterpieces at Hartford State Library. A field worker in voter registration and in the civil rights movement, including but not limited to Virginia and Mississippi, David participated in the March on Washington, in 1963. He moved to New York, in the late 1960s, renovating lofts and beginning an art career. Next came a move to Vermont, ancestral home on his fathers side. There he concentrated on revolver marksmanship, dynamited log jams, and sculpted.

David bought his first revolver, a .357 Magnum Blackhawk, at the age of 18, then shortly thereafter a Super Blackhawk. He taught himself fast-draw using holsters and belts of his own making.

In 1977, a friend in Vermont alerted David to an announcement in his newspaper of a metallic silhouette match. David showed up with a 6-inch Smith & Wesson Model 29 and a holster hed made and proceeded to mow down the competition shooting offhand, while his competitors took on the match shooting prone. Bradshaw shot high score, won the match, and was hooked from there.

David Bradshaw probably knows as much as anyone about the strengths and weaknesses of revolvers that are campaigned hard in the steel shooting game of silhouette. He has shot the best revolvers made into the winners circle, along the way winning the top trophies from Ruger, Smith & Wesson, Hornady, and Federal. After predicting the 10-inch Super Blackhawk .44 Magnum would rewrite the game of metallic silhouette, he shot that revolver his dubbed the Silhouette Super to victory in the first International Revolver Championship, in 1980.

David Bradshaw won many silhouette competitions, with a variety of revolvers. One of his finest was also one of Rugers finest, the .357 Maximum Blackhawk.

David worked closely with the main proponent of the .357 Maximum, Bill Ruger, Jr., on development of the revolver and Rugers .357 Maximum cartridge. There shortly followed the KS411N, the first stainless steel Super Blackhawk, which also bears Davids imprint. His first time out with the KS411N, David set the 140x160 revolver record, which he would later break. He is the only five-time IHMSA (International Handgun Metallic Silhouette Association) All-American, and he holds that to track a whitetail buck and take it with revolver to be a sacrament.

Author Photo

David Bradshaw (left) discussing revolver manufacture with Rugers Assistant Business Unit Director, Revolvers, Thomas Kelley, at the Ruger plant, in Newport, New Hampshire.

Photo by David Bradshaw

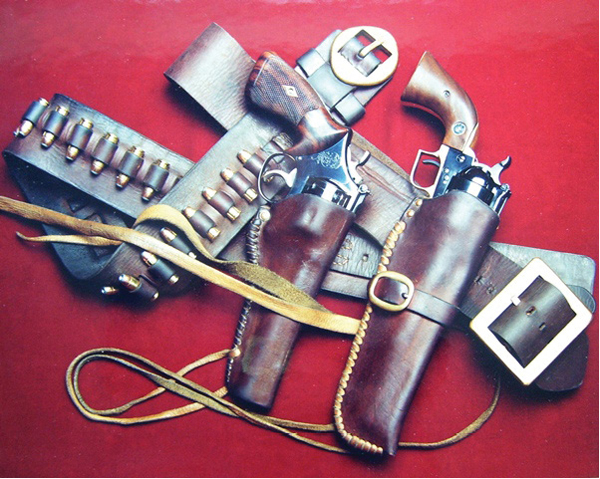

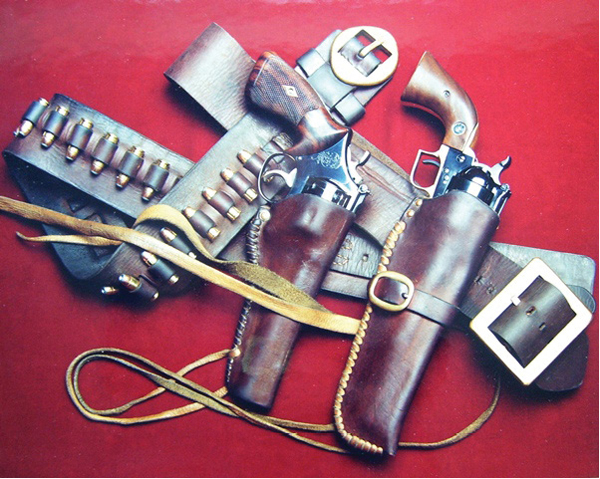

Leather and buckles by David Bradshaw from the mid-1960s. Left is a 6-inch Model 29-2 in a water-molded holster of heavily waxed English saddle leather. The belt with pull-through loops is three inches wide on single layer, top-grain cowhide, perfect for day-in, day-out wear. It also features cowhide lacing. This Model 29 was the revolver Bradshaw shot in his first metallic silhouette match, a match he won. On the right is a Super Blackhawk Old Model with factory brass grip frame. This is the revolver David shot in the first IHMSA International Championship, in 1977. The holster is water-molded, vegetable-tanned sole leather, very hard and thick, with elk lacing. The buckles are fashioned from -inch brass, with heavy copper tongues cut from old water pipe.

Photo by David Bradshaw

No longer shooting competitively, David Bradshaw still has chops!

Photo by David Bradshaw

Bradshaws factory custom convertible Bisley revolver resting on one of two Rugermobiles.

FOREWORD

Photo by Mark Gurne

The author, left, and David Bradshaw.

One carefully designed experiment is worth a thousand expert opinions. William B. Ruger, Jr.

A refrain of William B. Ruger, Jr., over the years, Bill attributes the quote above to the long dead author of an abstruse text on science and engineering. The principle is as valid today as ever, though, as vital to manufacturing as it is to learning. Worth rubbing off on marksmanship, too.

This approach to new manufacturing techniques to which William B. Ruger, Sr., was exposed developed during World War II. After a couple false starts, Ruger introduced his seminal semi-auto pistol in .22 Long Rifle. From this modest beginning, Ruger, in short order, turned American firearms manufacturing on its head. An ancient technique called lost wax casting became, for Ruger, what drop forging had been for Colts Manufacturing, Smith & Wesson, and Winchester. I have seen brilliantly detailed Chinese artifacts pots, tureens, vessels cast in copper and bronze by the lost wax process and that date back 6,000 years. Old as the process is, in practicality, it is as valid today as ever, submitting to the most exacting of steel alloy formulas. Now, after years of criticism directed at investment casting as being weak, we are forced to conclude that the person who utters such nonsense was educated at the School of Babble, or is otherwise numb between the ears.

Perhaps no public venue has proven the durability of Rugers lost wax casting as has handgun silhouette, where Ruger endurance remains unsurpassed. That durability proven on the firing line has carried directly to durability in the hunting fields. Ruger durability and Ruger design go hand-in-hand, no matter their use and application.