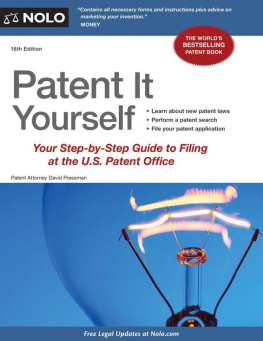

About the Authors

Richard Stim is an attorney specializing in intellectual property. He is the author of several other intellectual property books including Getting Permission: Using & Licensing Copyright-Protected Materials Online & Off (Nolo); Music Law: How to Run Your Bands Business (Nolo); and Profit From Your Idea: How to Make Smart Licensing Deals (Nolo). He writes the Dear Rich blog (http://dearrichblog.com) where he answers questions regarding intellectual property.

David Pressman has had over 40 years experience in the patent profession, as a patent examiner for the U.S. Patent Office, as a patent attorney for Philco-Ford Corp., Elco Corp., and Varian Associates, as a columnist for EDN Magazine and Entrepreneur.com, and as an instructor at San Francisco State University. He contributed the Patent, Trademark, and Copyright entries to the World Book Encyclopedia. Hes also an inventor, with two patents issued. When not writing, dabbling in electronics, programming, inventing, or playing his trumpet, he practices as a patent lawyer in San Francisco. Originally from Philadelphia, he has a B.S. in Electrical Engineering from Pennsylvania State University. He spent his first year in law school at the University of Pennsylvania and completed his second and third years at George Washington University, where he served on the Law Review and received a Juris Doctor degree. He is also active in the general semantics and vegetarian movements. His mother, Mildred Phillips, is also a writer, having composed lyrics for numerous published songs, including Bill Haleys Mambo Rock.

APPENDIX

A

Provisional Patent Applications

, these drawings can be informally prepared for purposes of the provisional patent application.

Pasteurization

As we explained in , Louis Pasteur discovered that by preventing exposure to air, a larger quantity and better quality of beer could be produced. Pasteurs processlater known as pasteurizationpartially sterilized the beer and subsequently was used to sterilize liquids such as milk and orange juice, as well as cheese. His Improvement in Brewing Beer and Ale was patented in France in 1871 and in the United States in January 1873.

Provisional Patent Application

A Provisional Patent Application for Pasteurization

I discovered a better way to brew beer and ale. My process prevents the wort (the boiled extract of malt or material seasoned with malt or other qualifying ingredient seasoned with hops) from exposure to air. The resultcompared to existing methods of beer productionis the production of a larger quantity of beer as well as a beer that is more aromatic and less likely to deteriorate in transit or storage.

I accomplish this by expelling the air from the boiled wort while it is confined in a closed vessel (or vessels).

The attached drawing helps to explain my invention. Three casks AAA (Fig. 1), made of iron, wood, or other suitable materials, are supported on stands below a water pipe E. The water pipe has branches, each with a valve, and at the end of each branch, a flexible hose and spray nozzle P. On another stand T is an apparatus MM that generates carbonic-acid gas. The carbonic gas is supplied to the casks and is released from the casks at the escape tubes X which extend into cups or chambers V from which the gas can be collected by a gasometer.

The wort is prepared in the usual manner and while boiling hot is placed in a cask. Carbonic-acid gas is conveyed into the cask for the purpose of expelling air. There must be a thorough penetration of carbonic-acid gas into the liquid to expel all contained air.

Then, the water pipe sprays the cask to cool it. A trough C is placed below the casks to collect the water. As the temperature is reduced to about 20 to 23 degrees Celsius (6873 degrees Fahrenheit), the yeast or fermenting material is added to induce fermentation. After first fermentation, the beer can be sent through the valves R into casks or barrels for future use.

The beer does not have to be removed and fermentation can be completed in the cask. But in this case, a small quantity of air may be drawn into the cask to speed fermentation. The air drawn into the tube should be filtered through cotton or passed through a hot tube to kill or extract any germs that it may contain. The apparatus shown is adapted for making small quantities of beer but the capacity may be varied quite easily.

Patent

Improvement in Brewing Beer and Ale No. 135,245

Be it known that I, Louis Pasteur, of the city of Paris, France, have invented certain new and useful improvements in the Process of Making Beer for which Letters Patent were granted to me in France on the 28th day of June 1871; and I do hereby declare the following to be a full, clear and exact description thereof, reference being made to the accompanying drawing making part of this specification and the letters of reference marked thereon.

Previous to my invention in the process of making beer it has been customary to permit the exposure of the wortthat is the boiled extract of malt or other material seasoned with hop, or other qualifying ingredientto the action of atmospheric air. I have discovered that by contact in the usual way with air during the process not only is the quality of the beer produced much impaired, but also that less quantity is made from a given amount of wort that can be otherwise produced.

Based on this discovery and the idea of performing the process of brewing without the presence in the wort of atmospheric air, my invention has for its object to produce a better quality and greater quantity of wort, and to afford a beer which shall also embody the quality of greater changes of climate and in transportation and use; and to these ends my invention consists in expelling the air from the boiled wort while confined in a closed vessel or vessels and then cooling it by the application of sprays of water to the exterior of such vessel or vessels as will be hereinafter more fully explained.

To enable those skilled in the art to fully understand and practice my improved process for the manufacture of beer, I will proceed to more fully describe it, referring at the same time by letters to the accompanying drawing in which I have shown an apparatus adapted to carry on my said improved process.

At Figure 1, A A A represent three casks or tanks, which may be made of galvanized iron, wood, or other suitable material, and which are supported on suitable stands b, as represented. Above the series of cylinders or vessel A is arranged a water supply pipe, E, from which depend branch pipes (one over each of the vessels A), provided with cocks r, and having attached to their lower ends flexible tubes or hose s, which in turn carry at their lower extremities spray-nozzles P. Upon a suitable stand or shelf, T, is located an apparatus M M, for the generation of carbonic acid gas, which is to be supplied therefrom to the vessels A for purposes to be presently explained and by means of tubes connected at W to the said vessels. The escape of the gas is permitted through exit or escape tubes at x which extend siphon-like into water cups or chambers v from whence the gas may be collected in a gasometer.

I have shown the connection of the gas generator with only one of the vessels; but it will be understood that the others may be similarly connected.

The spray-nozzles P are located about centrally over each of the vessels A, which should be made slightly convex or dome-shaped on top, and so that the jets of water discharged there from will fall like rain on the tops of the said vessels and trickle down their sides as illustrated by the dotted lines in Fig. 1. Around the base of each vessel A is arranged a circular trough, which catches the water and from which the water is left off by a tube, I, into a conductor or discharge trough,