SERIES EDITOR: TONY HOLMES

OSPREY COMBAT AIRCRAFT 82

A-26 INVADER UNITS OF WORLD WAR 2

JIM ROEDER

CONTENTS

PREPARING THE INVADER

B uilt by Douglas, the A-26 Invader was a twin-engined, single pilot attack bomber that boasted a slight family resemblance to its predecessor, the A-20 Havoc, although it was considerably faster (with a maximum speed of 373 mph, versus 317 mph for the A-20). First flown on 10 July 1942, the A-26 was pronounced ready to enter service by the test pilot at the controls for this inaugural flight, Ben Howard. Yet, despite his enthusiasm, two years would pass before the Invader finally made its combat debut in July 1944 with the A-20-equipped 13th Bombardment Squadron (BS), 3rd Bomb Group (BG) in New Guinea.

Prior to engaging the enemy, the A-26 had been issued in growing numbers to units in the USA as air- and groundcrews gained experience on the new aircraft before commencing combat evaluation in the Pacific and European theatres. Pilots reported that the Invader was a stable, reliable and pleasant aircraft to fly, although its long, broad nose and close engine placement drew criticism from Havoc pilots in the 13th BS, as they felt that both restricted their vision when flying at lower levels. Nevertheless, the A-26 possessed excellent single-engine flight characteristics, even if one of its Pratt & Whitney R-2800 Double Wasp radials failed on takeoff. Once in action, it was found that the Invader could withstand considerable combat damage.

Prototype XA-26 41-19504 is seen here at Mines Field, Los Angeles, on 29 April 1943. Its distinctive propeller spinners were not adopted when the aircraft entered production due to engine cooling problems that arose when they were fitted

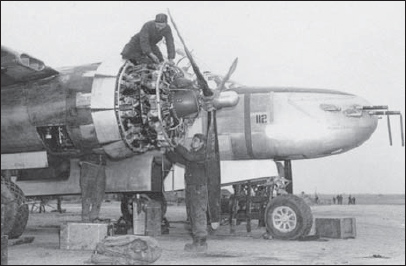

Nacelles removed, an early-build A-26B receives routine maintenance in the open somewhere in the ETO in early 1945. The Pratt & Whitney R-2800-27 radial engines were readily accessible once their close-fitting nacelles had been unfastened and carefully taken off

Another important attribute was that the A-26 aircrew requirement was one-third or even half that of any other medium or light bomber then in service with the USAAF. Just a pilot and rear gunner initially crewed the solid nose A-26B, and a bombardier/navigator was added with the advent of the A-26C with its Plexiglas nose section. The A-20 required a minimum of three aircrew, with a fourth added for the A-20J/K variants. As previously mentioned, the A-26B featured a solid nose housing six (increased to eight in later production A-26Bs) Browning 0.50-in machine guns. The A-26C had a Plexiglas nose section for a bombardier, with two 0.50-in guns mounted to starboard. The C-model was identical to the A-26B in all other respects, however.

The Invader was built from the outset to be flown by a solitary pilot, unlike previous American medium and light bombers. This young second lieutenant was photographed in the cockpit of an A-26B during his conversion onto the aircraft with a stateside training unit. A jump seat was also usually provided for either the navigator or flight engineer. Note the gunsight fitted to the instrument panel

Invaders were manufactured at two of Douglas plants, with its Long Beach, California, facility building A-26Bs and five Plexiglas-nosed A-26Cs at the very start of the latter models production run these were the only only C-models built at Long Beach, with the remainder being assembled at the Tulsa, Oklahoma, plant which produced both B- and C-models concurrently. Fuselages for both variants were assembled on the same lines at Tulsa, but manufacturing delays in the early stages of Invader production resulted in a slow delivery rate to the USAAF. The reasons for these delays were numerous, and included (but were not limited to) the incorporation of new equipment, together with design and tooling difficulties.

Fitted with an early flat top canopy, this A-26C was assigned to the 416th BG in the winter of 1944-45. The bombardiers feet can just be seen dangling through the open crew access hatch in the nose of the aircraft

Another hindrance was the large number of changes issued daily by the USAAF, which initially planned to replace all of its medium bomber aircraft with the Invader from late 1942. However, indecision as to the exact role the aircraft would fulfil resulted in myriad design changes and serious delays to its production schedule. Incorporating these changes in the production line without pause, along with other issues, caused the slow production rate. This initially resulted in more A-26Bs reaching the frontline. To ease the shortage of C-models in the USAAF, and to provide Invaders capable of carrying a bombardier, the Tulsa plant produced A-26C nose sections as field kits for units to install on existing A-26Bs. As many examples of the latter were fitted with a C-model nose, the serial number is the only certain way to determine if an A-26 was indeed built as a C-model, or was a B with a C nose added as a field modification.

Another early flat top Invader this time an A-26B provides the backdrop for personnel (both air-and groundcrew) from the 416th BG

While the Invader had many outstanding qualities, it also had its share of shortcomings. As previously mentioned, chief among them was restricted visibility due to the heavy canopy framing and the large size, and positioning, of the engine cowlings. Another was the fact that the primary means of cockpit entry and exit was through a hatch on the right side of the canopy. This hatch was hinged at the front and swung upwards and forwards, but there was a console containing instruments and switches in the centre of the cockpit so that while entry and exit was normally fairly easy, it could be difficult and extraordinarily time-consuming in an emergency.

Fitted with underwing gun pods, this A-26B suffered a nose gear failure whilst taxiing at Laon/Athies in early 1945. Both propellers have been badly damaged and the engines wrenched. The aircraft is also equipped with a large, heavily-framed hatch on the right-hand side of the canopy, which provided cockpit access. This early style hatch severely restricted pilot visibility

Prior to the commencement of the Invaders combat evaluation in the Pacific, the issue of limited visibility had been recognised by Douglas to the point where it had introduced an interim fix on the Tulsa and Long Beach production lines in June 1944. This took the form of a single, unobstructed, curved section of Plexiglas in place of the framed panels above and to the left of the pilot. Referred to as the revised flat top canopy, this modification helped to increase the pilots visibility forward but did not resolve the major issue of restricted vision over the engine cowlings. Apart from this simple alteration, the revised canopy was identical to the original flat top fitted to the first production examples, and it was incorporated into the Long Beach line from the A-26B-20DL and A-26B-15DT models, as well as the A-26C-15DT at Tulsa.

Next page