Contents

Contents

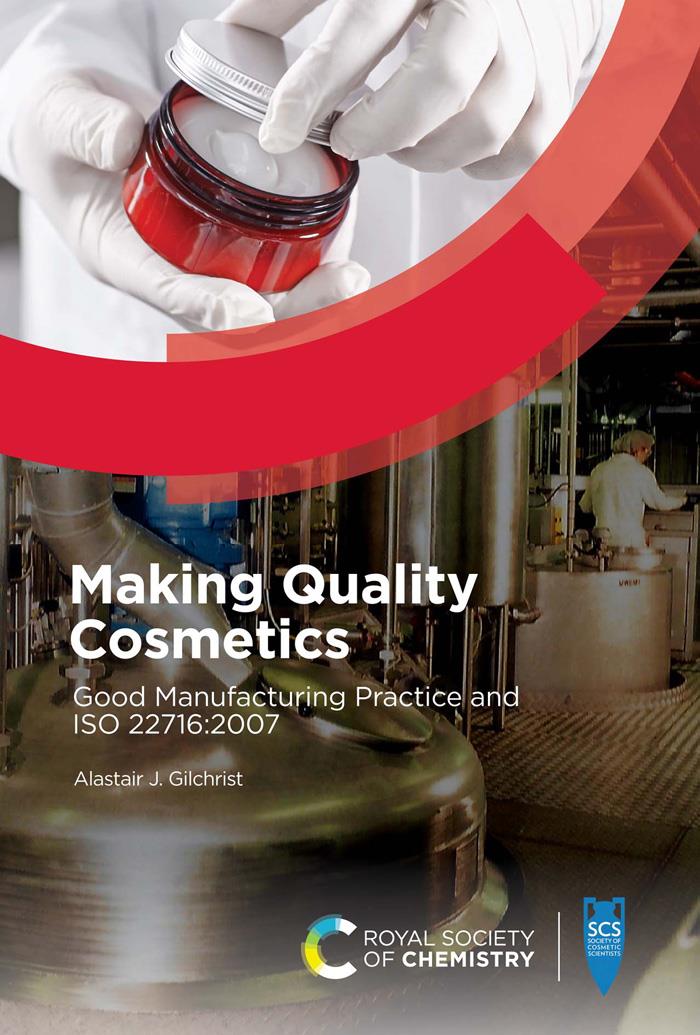

Making Quality Cosmetics

Good Manufacturing Practice and ISO 22716:2007

By

Alastair J. Gilchrist

Gilchrist Technical Services, UK

Email: ajg@gilchristtechnicalservices.co.uk

Making Quality Cosmetics

Good Manufacturing Practice and ISO 22716:2007

Print ISBN: 978-1-83916-514-6

PDF ISBN: 978-1-83916-639-6

EPUB ISBN: 978-1-83916-640-2

A catalogue record for this book is available from the British Library

Alastair J. Gilchrist 2023

All rights reserved

Apart from fair dealing for the purposes of research for non-commercial purposes or for private study, criticism or review, as permitted under the Copyright, Designs and Patents Act 1988 and the Copyright and Related Rights Regulations 2003, this publication may not be reproduced, stored or transmitted, in any form or by any means, without the prior permission in writing of The Royal Society of Chemistry or the copyright owner, or in the case of reproduction in accordance with the terms of licences issued by the Copyright Licensing Agency in the UK, or in accordance with the terms of the licences issued by the appropriate Reproduction Rights Organization outside the UK. Enquiries concerning reproduction outside the terms stated here should be sent to The Royal Society of Chemistry at the address printed on this page.

Whilst this material has been produced with all due care, The Royal Society of Chemistry cannot be held responsible or liable for its accuracy and completeness, nor for any consequences arising from any errors or the use of the information contained in this publication. The publication of advertisements does not constitute any endorsement by The Royal Society of Chemistry or Authors of any products advertised. The views and opinions advanced by contributors do not necessarily reflect those of The Royal Society of Chemistry which shall not be liable for any resulting loss or damage arising as a result of reliance upon this material.

The Royal Society of Chemistry is a charity, registered in England and Wales, Number 207890, and a company incorporated in England by Royal Charter (Registered No. RC000524), registered office: Burlington House, Piccadilly, London W1J 0BA, UK, Telephone: +44 (0) 20 7437 8656.

Visit our website at www.rsc.org/books

Printed in the United Kingdom by CPI Group (UK) Ltd, Croydon, CR0 4YY, UK

Preface

I have spent a large part of my working life in the development and manufacturing of good quality cosmetic products. I have been fortunate to work in facilities where quality was a priority and actions were taken on a daily basis to ensure that the product produced met clearly documented acceptance criteria.

Not all cosmetics are manufactured in quality-focussed environments and this can result in products of inconsistent appearance or performance in the market place, which can be disappointing for consumers. There are international standards which document what should be done but do not say how. The intention of this book is to provide manufacturers of cosmetic products, from start-ups to established companies, some guidance when they set up or improve their manufacturing facilities equipment or procedures.

Alastair J Gilchrist

Acknowledgements

I would like to thank all the people who have taught me about cosmetic science, manufacturing, engineering and quality throughout my career. I also thank individuals and companies who have kindly allowed me to use images. Without all this help this book would never have been written.

There is a lot of excellent equipment available to manufacture and package cosmetic products. I have worked with most of the suppliers mentioned in the text, and many others, integrating their equipment to create efficient, cost-effective and GMP-compliant manufacturing systems.

I would also like to thank my wife who supported while I researched and wrote the book.

Author Biography

Alastair Gilchrist (BSc., CChem, MRSC, Eur. Chem, CSci) is a graduate in chemistry from the University of Manchester. He started his career in the quality control department of Sterling Winthrop in Newcastle upon Tyne. After a few years he joined Bristol Myers Company Limited which became part of Bristol Myers Squibb as a development chemist, working on Clairol hair care and hair colour products as well as Mum deodorants and Mr Muscle household products. He had an opportunity to become manufacturing manager, where making cosmetics became his day job. Mr Muscle was sold, but, Clairol relaunched Herbal Essences, which brought a whole new set of challenges to the factory which was not ready for what became a very successful brand. Alastair successfully led the re-engineering of the manufacturing department to cope with the new production demands, learning a lot about hygienic engineering in a short span of time.

After the sale of Clairol to Proctor and Gamble, Alastair set up an independent consultancy, Gilchrist Technical Services Limited, and he has continued to work mainly in the cosmetics industry since 2003 helping companies set up cosmetic manufacturing units or improve the facilities that they already have. Experience gained while working in the pharmaceutical industry and performing a key role in the design, build and qualification of a vaccine manufacturing facility has been invaluable, which has helped in writing the compliance sections of this book.

Glossary

Aerosol concentrate usually a liquid but sometimes a powder which is filled into an aerosol can before the valve is crimped on and the can is gassed with propellant.

Bio-critical a raw material or product which is susceptible to microbiological contamination.

Brine a saturated solution of sodium chloride in water (26.45% w/w).

Carton a cardboard box to protect, enhance the appearance of a product or contain several components (secondary packaging).

Check valve Non-return valve.

Clean a surface or item of equipment which is free from dirt, dust or all traces of products.

Collating assembly of retail packs into units ready for distribution.

Compatibility testing similar to stability testing but in this case the interactions between the product and the primary pack are being investigated.

Density weight per unit volume. For cosmetics this is usually expressed as g/ml (g ml1).

Dispensary weighing area for raw materials to be used in manufacturing.

Girt also known as a sheeting rail. It is a horizontal steel structural member in a framed wall.

Godet a small aluminium or tinplate pan which pressed powders are compacted into prior to assembly into a finished pack.

Hostile (material) a raw material or product which is not susceptible to microbiological contamination (not bio-critical).

Hygienic (engineering) use of hygienically designed components and principles that accelerate cleaning and prevent product deposits.

Indie brand independently owned (beauty) brand.

Inverter a device which alters the frequency of an alternating current and can be used to control the speed of an electric motor.

Labelling application of a label and often a batch code to a primary pack.

Manufacturing the conversion of raw materials into batches of bulk product.

Organoleptic test performed using senses. For cosmetics, appearance, colour and odour.