Wireman - Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series

Here you can read online Wireman - Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2013, publisher: Reliabilityweb com, genre: Business. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Wireman: author's other books

Who wrote Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series? Find out the surname, the name of the author of the book and a list of all author's works by series.

Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

www.terrywireman.com

TLWireman@Mindspring.com

Reliabilityweb.com

Maintenance Strategy Series

Volume 4

Successfully Utilizing CMMS/EAM Systems

Terry Wireman

ISBN 978-1-939740-13-7

Copyright 2013 Reliabilityweb.com

Printed in the United States of America All rights reserved.

This book, or any parts thereof may not be reproduced, stored in a retrieval system, or transmitted in any form without the permission of the publisher.

Opinions expressed in this book are solely the authors and do not necessarily reflect the views of the Publisher.

Publisher: Terrence OHanlon

For information: Reliabilityweb.com

www.reliabilityweb.com

PO Box 60075, Ft. Myers, FL 33906

Toll Free: 888-575-1245 | Phone: 239-333-2500

Email:

TABLE OF CONTENTS

Maintenance Management Strategy ComponentsAssessing Maintenance Organizational Issues

Maintenance Organizational Attitudes

Maintenance Management Maturity GridMaintenance Planning

Maintenance Work Orders

Computerization of Manual Systems

Application of CMMS/EAM SoftwareDo I Really Need a CMMS/EAM System

CMMS/EAM System Check Sheet

Selection Tips1. Develop the Project Plan and Resource Requirements

2. Update All Current Records

3. Software Installation

4. Data Entry/Migration

5. System Introductions and Updates

6. CMMS/EAM System Training

Common Selection and Implementation ProblemsProper Staffing

Asset UtilizationEAM A ReviewIntroduction

Standard Cost Justification

Detailed Cost SavingsCMMS/EAM System Trends

ISO-9000 Certification

More Distant Future

The Far Distant Future

ConclusionCMMS/EAM System ProblemsEquipment SubsystemAre We There Yet?

Who Will Feed the Monster?

Downsizing or Dumbsizing: Which?

The Challenge of ChangeEquipment Efficiency Case Studies

Overall Equipment Effectiveness Case Studies

INTRODUCTION

Volume 4 CMMS / EAM Systems

In this volume, the topic of a computerized maintenance management system (CMMS) is discussed. In the first volumes of the Maintenance Strategy Series, almost all of the documentation necessary to management maintenance can be handled manually. However, with the addition of the maintenance work management processes in the last volume (Volume 3 of the Maintenance Strategy Series), the documentation and data analysis necessary to be efficient has increased.

It is still possible for some maintenance departments to manage their information manually. However, it is more efficient to use a properly-designed computer system to accomplish these tasks. Continuing with manual systems would be analogous to a companys accounting department still trying to utilize pens and lined ledger paper to track the company financials. Given the current stage of computer technology, it is much more logical to use a computer system to track and manage the necessary business information to manage maintenance properly.

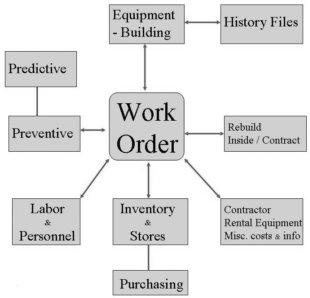

A computerized maintenance management system is designed to simplify the data collection and analysis. As will be explained in this text, the basic modules of the CMMS are designed to facilitate the management of the various components of maintenance, such as:

- Preventive maintenance

- MRO inventory and procurement

- Work order management, including the tracking of

- Labor costs and information

- Material cost and information

- Contracting cost and information

When the CMMS is utilized across multiple plants, and corporate managers use the data to manage the assets at an enterprise level, the system acronym changes to an EAM system or Enterprise Asset Management system. This text will help the reader differentiate between the two types of systems and provide guidelines on when to use each type of system.

The text contains valuable information that will help any one using a CMMS / EAM system, whether they are in the selection, implementa- tion, or utilization phase with their system.

OVERVIEW

The Maintenance Strategy Series Process Flow

Good, sound, functional maintenance practices are essential for effective maintenance / asset management strategies. But what exactly are good, sound, functional maintenance practices? The materials contained in this overview (and the overview for each of the volumes in the Maintenance Strategy Series) explain each block of the Maintenance Strategy Series Process Flow. They are designed to highlight the steps necessary to develop a complete maintenance / asset management strategy for your plant or facility. The activities described in the Process Flow are designed to serve as a guide for strategic planning discussions. The flow diagram for the Maintenance Strategy Series Process Flow can be found at the end of this overview.

Authors Note

Many individuals may believe that this type of maintenance strategy program is too expensive or time consuming to implement, especially when there are advanced predictive or reliability techniques that might be employed. Yet there is a reason for the sequencing of the Maintenance Strategy Series process flow. If attempts are made to deploy advanced techniques before the organization is mature enough to properly understand and utilize them (basically, the I want results now short-term focus), they will fail. The reason? Developing and implementing a sustainable maintenance / asset management strategy is more than just distributing a flow chart or dictionary of technical terms. It is an educational exercise that must change a company culture. The educational process that occurs during a structured implementation of basic maintenance processes must evolve into more sophisticated and advanced processes as the organization develops the understanding and skills necessary.

If an individual is to obtain a college degree, it may involve an investment of four or more years to achieve this goal. Likewise, if a company is to obtain an advanced standing in a maintenance / asset management strategy, it may take up to four years. It is not that someone cannot, through years of experience and education, design their maintenance / asset management process in a short time period. It will, however, take the entire organization (from senior executive to shop floor employees) this amount of time to become mature in their understanding and utilization of the process. Although there will be incremental benefits achieved along the journey to maintenance / asset management excellence, the true benefits are not realized until there is a complete organizational focus on maximizing all aspects of the investment in the assets. It is this competitive focus that separates long-term, sustainable success from a short-term flash of improvement.

Figure I-4 Work Order and MRO Cost Relationships

In the beginning, it is necessary for a plant or facility to decide it is necessary to improve their maintenance / asset management strategy. The business reason for the needed improvement can be multi-faceted, but would likely include:

- Poor Return On Investment (ROI) for the total plant or facility valuation

- Poor throughput for the design of the plant

- Inability to meet production demands

- High cost of occupancy for a facility

- Excessive downtime

- Production inefficiencies

Once the decision has been made to develop / improve the maintenance/ asset management strategy, the Maintenance Strategy Series process flow diagram should be followed. It begins with Preventive Maintenance.

1. Does a PM Program Exist?

Next pageFont size:

Interval:

Bookmark:

Similar books «Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series»

Look at similar books to Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Successfully Utilizing CMMS/EAM Systems: Maintenance Strategy Series and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.