Wireman - MRO Inventory and Purchasing: Maintenance Strategy Series

Here you can read online Wireman - MRO Inventory and Purchasing: Maintenance Strategy Series full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2013, publisher: Reliabilityweb com, genre: Romance novel. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:MRO Inventory and Purchasing: Maintenance Strategy Series

- Author:

- Publisher:Reliabilityweb com

- Genre:

- Year:2013

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

- 60

- 1

- 2

- 3

- 4

- 5

MRO Inventory and Purchasing: Maintenance Strategy Series: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "MRO Inventory and Purchasing: Maintenance Strategy Series" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Wireman: author's other books

Who wrote MRO Inventory and Purchasing: Maintenance Strategy Series? Find out the surname, the name of the author of the book and a list of all author's works by series.

MRO Inventory and Purchasing: Maintenance Strategy Series — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "MRO Inventory and Purchasing: Maintenance Strategy Series" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

www.terrywireman.com

TLWireman@Mindspring.com

Reliabilityweb.com

Maintenance Strategy Series

Volume 2

MRO Inventory and Purchasing

Terry Wireman

ISBN 978-1-939740-11-3

Copyright 2013 Reliabilityweb.com

Printed in the United States of America All rights reserved.

This book, or any parts thereof may not be reproduced, stored in a retrieval system, or transmitted in any form without the permission of the publisher.

Opinions expressed in this book are solely the authors and do not necessarily reflect the views of the Publisher.

Publisher: Terrence OHanlon

For information: Reliabilityweb.com

www.reliabilityweb.com

PO Box 60075, Ft. Myers, FL 33906

Toll Free: 888-575-1245 | Phone: 239-333-2500

Email:

TABLE OF CONTENTS

MRO Analysis

Organization Configurations

Stores Locations and Organization

Part Identification

Stocking Policies and Calculations

Inflated Inventories

Determining Storage Areas and Equipment

Determining the Tracking System

Finding Balances in MRO Management

Determining Proper Stocking Policies

Types of Spare Parts

Factors that Drive MRO Inventory Management

Work Flows in the MRO Inventory Department

Free Issue Items

Direct Purchase Items

Stocking Tools

Tracking Tools

Replacing Tools

Purchasing Tools

Ordering Stock Items

The Approval Process

The Receiving Process

Issues with Rebuilds

The Return-to-Stock Process

Controlling Stock Overages

Adding Spare Parts

Deleting Stock Items

MRO Improvement Initiatives

MRO Materials Top Ten Enablers

MRO Inventory and Purchasing

Inventory and Procurement Problems

INTRODUCTION

Volume 2: MRO Inventory and Purchasing

MRO stands for maintenance, repair, and overhaul. In the context of this publication, MRO inventory will include disposable and repairable equipment spare parts and consumable maintenance supplies. A more definitive list of these item types is as follows:

- Disposable spare parts whose inventory levels are replenished by reordering from a supplier.

- Disposable spare parts, whose inventory levels are replenished in a fabrication shop (internal or external).

- Spare parts that can be rebuilt and returned to inventory after the repair.

- Critical spares that need to be monitored periodically to guarantee they are in prime condition when needed.

- Shop items such as steel, sheet metal, or tubing.

- Maintenance supply items.

- Manufacturing and general plant supply items such as janitorial supplies, clothing items, etc.

- Tools and maintenance test equipment.

- Parts and supplies waiting to be used or project activities.

- Excessive parts and equipment left over from projects and awaiting resolution (stock, return, or disposal)

Although this information seems very straightforward, it is surprising to find the current status of MRO spare parts management. In most organizations, the storeroom provides poor service levels. This results in hoarding and pirating of spare parts. Such hoarding, of course, will increase the dollar value of the spare parts a company has on hand. In addition, there are many inaccuracies in the stock counts of items on hand in the storeroom. These inaccuracies result in either having too many spare parts on hand, or delays in work execution due to having too few spare parts on hand. One final problem that is encountered in larger companies is the lack of tracking of the items in remote storerooms. This problem typically leads a company to carry excessive inventory, which increases the overall MRO costs for a company.

Each of these problems has an impact on the efficiency of the maintenance organization. It is not that these conditions are deliberate. They occur because personnel are trying to circumvent the MRO controls. The maintenance personnel try to circumvent these controls because they see them as an obstacle to keeping the equipment operating properly.

From an inventory control perspective, it is necessary to have the right parts, the right number of parts, and properly-managed inventory. This control is necessary if the inventory and purchasing organizations are going to support the equipment maintenance department. Proper controls are important because spare parts cost may make up 4060% of the total maintenance budget. For this reason, inventory management for MRO spare parts must be given close consideration.

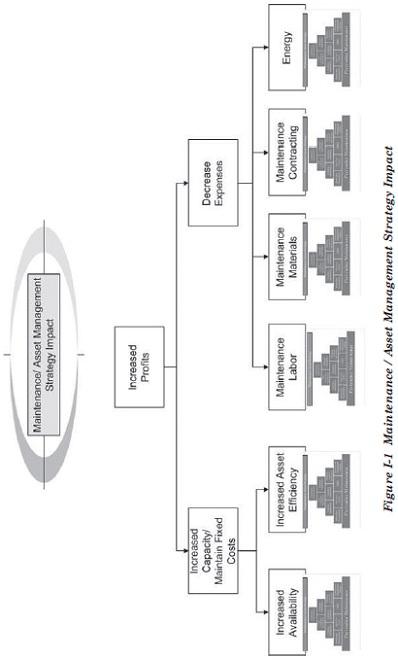

Figure I-1 shows the relationship between maintenance materials and plant profitability. As can be seen, materials typically have the focus of being able to decrease expenses. Of course, decreased expenses will increase profits because expense dollars not spent drop to the bottom line. Therefore, controlling MRO material costs is a quick way to increase profits as some companies see it. This view is shortsighted, however, because decreasing MRO material costs finally will reach a level that decreases profitability, due to increased equipment downtime and reduced capacity.

The impact that MRO parts can have on capacity is highlighted by looking at the left side of Figure I-1. The left side of the diagram shows that increased capacity is achieved by increasing availability or increasing the efficiency of an asset. If the proper MRO spare parts are not available when needed, increased down time of the equipment can result. This added down time, of course, will reduce availability. If the equipment cannot meet the production schedule, then either late shipments or increased cost such as overtime to produce the product will be incurred. Both of these situations will decrease profitability.

Therefore, it can be seen that a proper balance needs to be achieved. Having too many spare parts makes it difficult to control expenses, whereas having too few spare parts makes it difficult to achieve the proper amount of equipment capacity. Consider Figure I-2, which lists typical material-related delays for maintenance technicians. Consider the amount of time maintenance technicians spend waiting on materials, traveling to get materials, and transporting materials to the job site. These delays can consume a considerable amount of time. When dealing with maintenance technicians, time is money.

Material-Related Waste

- Waiting on materials

- Travel time to obtain materials

- Time to transport materials to job site

- Time to identify untagged materials

- Time to find substitute materials

- Time to find parts in reomte/ alternative locations

- time to obtail Purchase Order approvals

- Cost of processing Purchase Order

- Time lost due to :

- Other crafts having material problems

- Wrong materials planned, ordered, or delivered

- Materials out of stock

Figure I-2 Material-Related Waste

The role of time and, therefore, productivity, is highlighted in Figure I -3. In looking at the wrench time for a technician, it can be seen that if a technician works at a 30% rate, versus a 60% rate, the dollar value can be considerable. What makes the difference and a 30% wrench time, versus a 60% wrench time? It is the amount of delay a technician experiences in attempting to perform a particular job. If, as depicted in Figure I2, technicians encounter multiple or lengthy material related delays, their wrench time will be significantly lower. Depending on the actual hourly rate of a maintenance technician, significant material-related delays can greatly increase the overall maintenance expenses.

Next pageFont size:

Interval:

Bookmark:

Similar books «MRO Inventory and Purchasing: Maintenance Strategy Series»

Look at similar books to MRO Inventory and Purchasing: Maintenance Strategy Series. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book MRO Inventory and Purchasing: Maintenance Strategy Series and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.