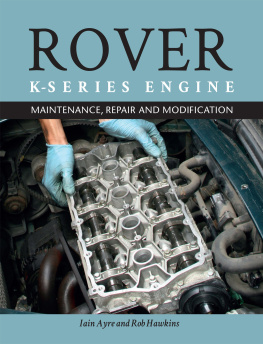

ROVER

K-SERIES ENGINE

MAINTENANCE, REPAIR AND MODIFICATION

ROVER

K-SERIES ENGINE

MAINTENANCE, REPAIR AND MODIFICATION

Iain Ayre and Rob Hawkins

THE CROWOOD PRESS

First published in 2018 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2018

Rob Hawkins and Iain Ayre 2018

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of thistext may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 394 3

CONTENTS

CHAPTER 1

INTRODUCTION: HISTORY OF THE K-SERIES

The Rover K-Series Engine was launched in 1988 in the Rover 200, and also ended up in the 100, the 400 and the MGF and TF. It was built by Rover subsidiary Powertain Ltd, in 1.1-, 1.4-, 1.6- and 1.8-litre capacities.

The first phrase to come to a petrolheads mind when somebody says K-series is the related phrase blown head gasket. The engine will, however, handsomely reward those who make the effort to sort it out.

Its architecture was unusual in that it was constructed as a sandwich, with cylinder head bolts running down through the entire engine to locate at the bottom. It was also unusual in being cast by low-pressure techniques, with molten aluminium pumped in from below, which reduced both overall weight and casting rejection rates.

Block and head were both cast in aluminium, with steel cylinder liners in the block, and five main bearings. It has either single or double overhead camshafts running in a camshaft cradle rather than separate bearings. The VVC, or variable valve control system, allows a flat torque curve and smooth power curve right up to the cut-off at 7,200rpm.

It has to be faced that the K-series engine has a bad reputation for blowing head gaskets, brewing up and destroying itself, but there are two points to be made here.

First, the design faults that caused this have been solved, and with the fixes applied, you can trust a K-series engine as much as any other, and can take advantage of its many benefits and good features.

Second, design faults sometimes dont appear until real-world production prototype testing by the first customers has been applied for several years, after which the engine may have a terminal PR problem. For instance, some BMW engines dissolved when they were run on sulphur-rich Nicaraguan petrol, which was discovered the hard way. Now a lot of people think that BMW engines are made of expensive porridge. Some Jaguar V8s have a faulty timing chain tensioner and can self-destruct at 60,000 miles (100,000km), although prophylactic pre-explosion replacement of a cheap plastic part solves the problem.

Even attempts to provide absolute reliability can misfire: Rolls-Royces 4-litre straight-six has thirty-nine studs holding its cylinder head down, which, with a compression ratio of 6.4:1, could be regarded as overgenocide rather than just overkill. The RR engines never blow their solid copper head gaskets, but thirty-nine steel studs corroding into an aluminium cylinder head generate their own potentially massive problem when you try to get the cylinder head off sixty years later.

The Triumph Stag engine is another good and particularly relevant example, with its terrible reputation for overheating, warpage and blown head gaskets. An engineer who was involved with it maintained that with good head gaskets, it was a magnificent engine as long as the cooling system in the car was operating above something like 90 per cent efficiency. Unfortunately, cheap antifreeze, neglect and age inevitably reduce the efficiency below 90 per cent, and then youre stationary in a cloud of steam on the hard shoulder, and in deep financial trouble.

A common, effective and cost-effective cure was a Rover V8 engine transplant.

Innovation always brings risks, and you cant test for everything. The A-series BMC engine got it right, and so did the Chevy 350: they are fine, safe, solid designs, and deserved their combined 100 years of production but you have to move on.

Rover didnt have any choice about whether to carry on with the K-series once launched, even when it became obvious that it had a few deficiencies. Going back to the A-series wasnt an option.

Some Porsche Boxster engines suffer from several major design faults, two of which can result in a crankcase full of shiny mechanical mince and a 10,000 bill for a new but still compromised engine: the good news is that theres just about room to replace a failed Porsche engine with an all-aluminium descendant of the Chevy 350, a 400bhp pussycat that also improves the balance and the fuel efficiency of the car. Even that has its faults, though if you dont change the oil regularly, the valve train apparently gets a bit noisy at 200,000 miles (320,000km).

Rather like friends, you have to decide whether you like particular cars and engines well enough to tolerate their faults. Unlike the faults of friends, those of the K-series engine can be sorted out relatively easily and quickly, after which the engine will be a loyal, lightweight, powerful and reliable chum for many years to come. On balance, the authors reckon the K is worth the effort.

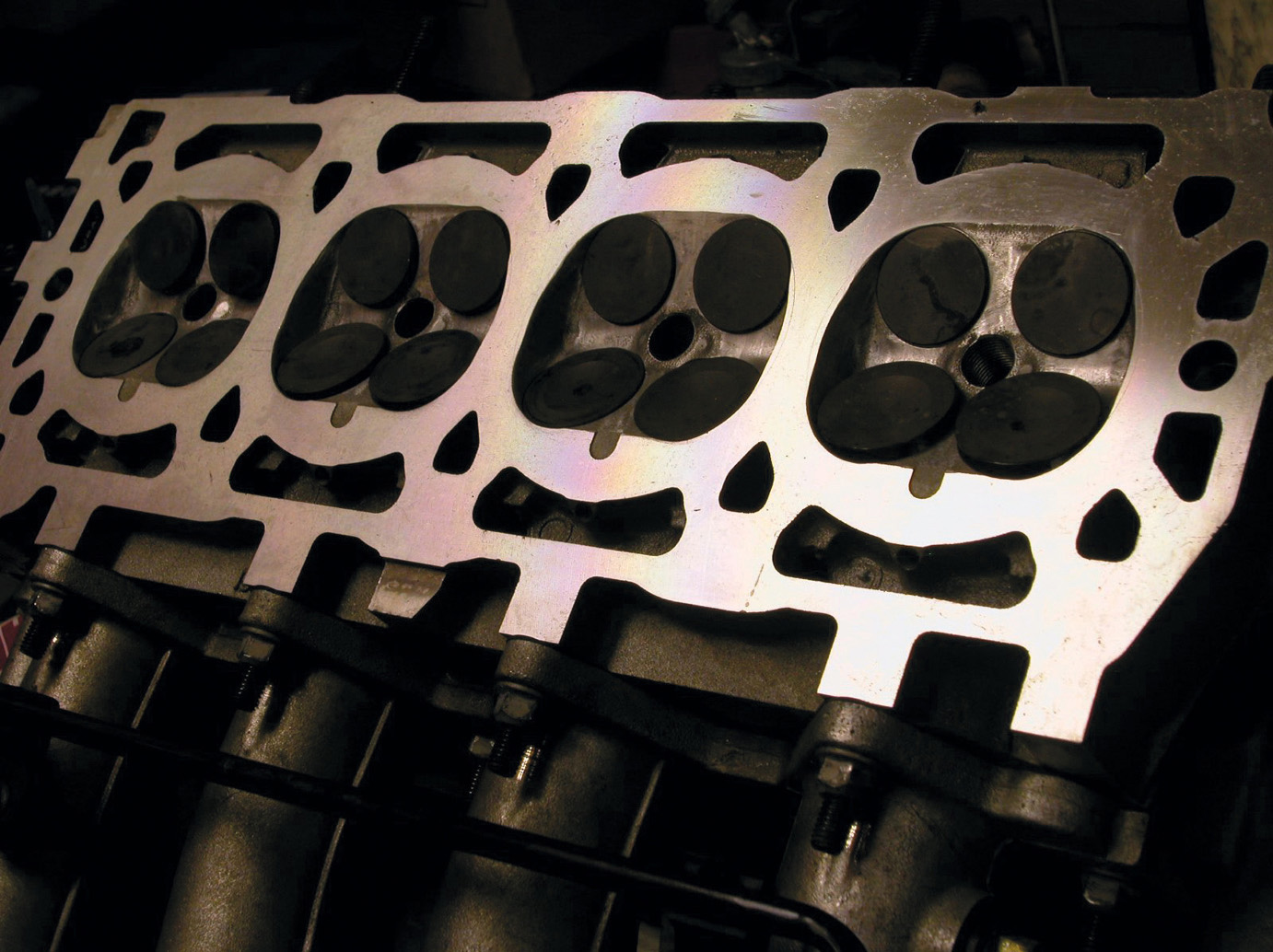

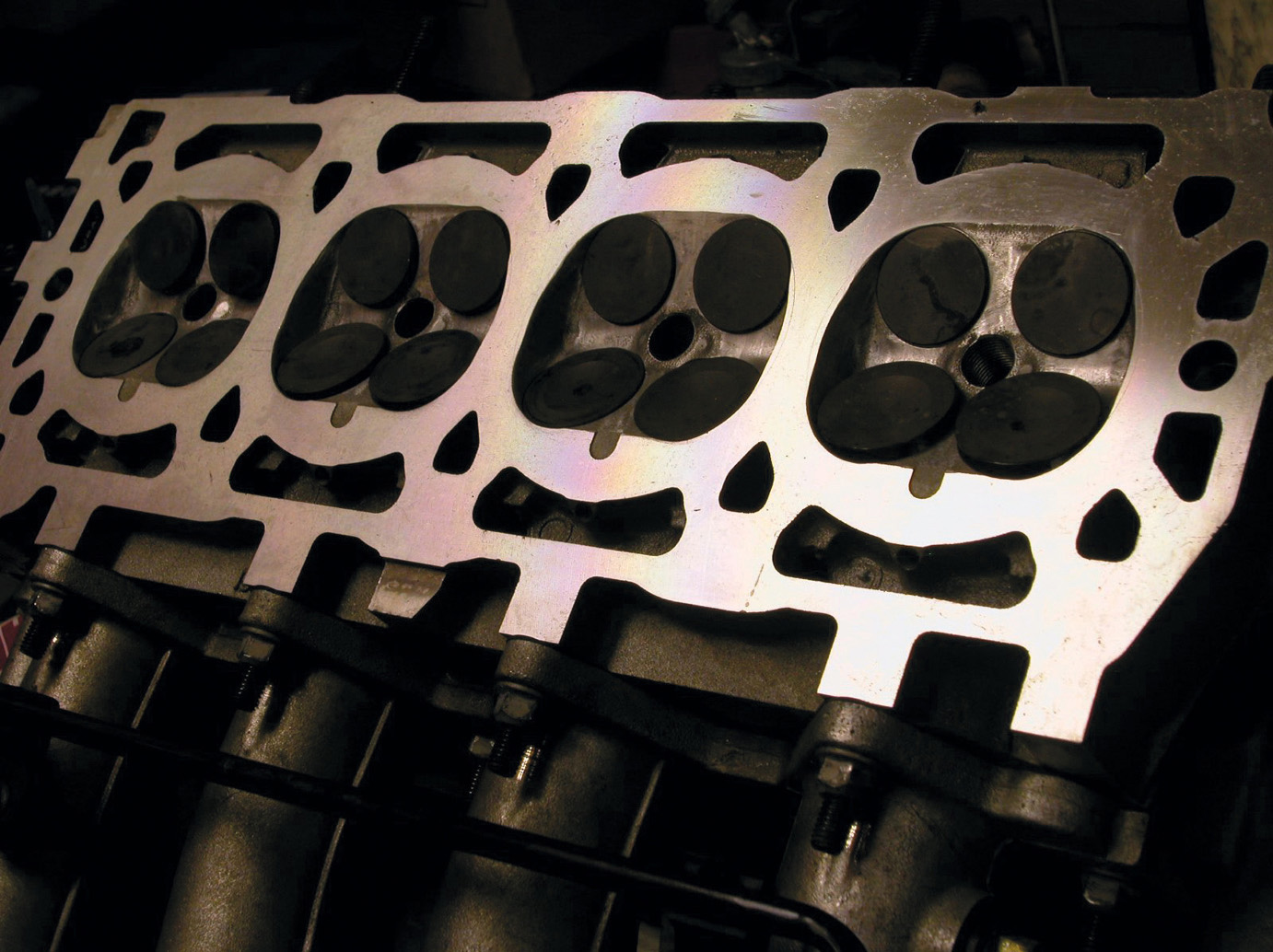

Co-author Rob Hawkins (left) gets stuck in, pulling a K-series cylinder head off to change the gasket.

GTM definitely did have a choice as to whether they used the K-series. Being kit car people and therefore creative and clever, they decided that its lightness, toughness and decent power were worth a bit of effort.

SUCCESSOR TO THE A-SERIES

In 1984, there was talk of a replacement for the venerable A-series engine, which had first seen service in 1952 in 803cc, 30bhp form in the Austin A30, and which would finally cease production with the last Mini in 2000.

At the time, Spen King was in charge of BL Technology at Gaydon, and the ECV economy car was brewing up, with an alloy 3-cylinder lean-burn engine. It wasnt an ancestor of the K-series, but it was certainly an influence.

Lean-burn was the focus of much attention in the early 1980s. The stoichiometric or theoretically perfect ratio of air to fuel for the most efficient extraction of energy from petrol is 14.7:1. However, both Ford and BL were achieving ratios of up to 20:1 on part throttle settings, resulting in dramatic savings on fuel. This books joint author Iain Ayre was writing for

Next page