Jacobs Terry - Good design practices for GMP pharmaceutical facilities

Here you can read online Jacobs Terry - Good design practices for GMP pharmaceutical facilities full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2017, publisher: Taylor & Francis, genre: Business. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Good design practices for GMP pharmaceutical facilities

- Author:

- Publisher:Taylor & Francis

- Genre:

- Year:2017

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

- 60

- 1

- 2

- 3

- 4

- 5

Good design practices for GMP pharmaceutical facilities: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Good design practices for GMP pharmaceutical facilities" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Jacobs Terry: author's other books

Who wrote Good design practices for GMP pharmaceutical facilities? Find out the surname, the name of the author of the book and a list of all author's works by series.

Good design practices for GMP pharmaceutical facilities — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Good design practices for GMP pharmaceutical facilities" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

Edward J. Tannebaum, AIA

Novel drug delivery is an extremely important aspect of the development of a drug product. New methods of drug delivery have been developed to both improve the drugs entry into the body and extend the life of the drugs financial viability through extending its patent. This article describes unique developments in forms of drug delivery, and provides an overview of drug delivery resources.

A drug delivery method has multiple goals: to simplify the actual delivery by improving the ease of use, to minimize the side effects of introduction into the body, to direct the introduction of the product to its specific location of need, and to manage the dosage delivery from immediate to sustained or extended release accurately. Many drugs require unique processing to develop means of achieving the most direct method of applying the active chemical compound to its intended delivery point. At the same time, due to patent expirations, new methods of physical delivery may provide an extension of the drugs life span as a proprietary product within a drug manufacturers portfolio. The combination of improving delivery options and the financial implications of improved uniqueness has dramatic effects on both the products position in the marketplace and its long-term benefit to the patient.

The design of facilities with compliant construction and meeting regulatory requirements poses a variety of challenges. The design of facilities for these novel drug delivery products ranges from utilizing existing processes to the invention and utilization of newer processes that may have been used formerly for other industries and must be modified to work within a Good Manufacturing Practice (GMP) environment. Starting with the early stages of development, the project progresses from a careful analysis of the risk-based approach to scale-up and commercialization, meeting the intent of regulatory agency submissions and their clinical trial stages.

The development of unique molecules that are competitive to produce and approvable by the worldwide regulatory agencies is a primary objective when developing novel drug delivery methods.

As worldwide drug manufacturing has become more subject to counterfeiting, along with the abuse of drug forms, it has become necessary to reformulate existing drugs in unique ways to make the drugs more difficult to counterfeit or to reformulate finished forms into illegal forms of concentration, especially with controlled substances. New methods to produce molecules that are not reproducible have become a valuable addition to drug development. Inherent molecule processes that destroy an active chemical when the particles composition is altered dramatically reduce the possibilities for counterfeiting and limit the use of active ingredients for illicit purposes.

New, convenient methods of drug delivery that improve the security of accurate dosing, extended-release capabilities, and dermatological to transmucosal delivery are among the many delivery systems being added to product formulations. High-impact tablet formulations that resist tampering will extend the life of existing controlled substance products due to their ability to limit adulteration; these will become more prominent in the coming years. Electronic, PC-based system implants are among the newer forms of delivery that will ensure accurate, timely dispensing of drugs, for both inpatient and outpatient use.

The following forms of delivery for drug products are an example of these unique developments:

Advanced controlled-release technologies

Bioavailability enhancement

Insoluble actives

Unstable actives

Potent and toxic actives

Small-molecule delivery

Taste masking (for liquid and solid presentations)

Contract development and manufacturing organizations (CDMOs) are in the forefront of the creation and development of these unique delivery platforms. Development firms concentrate their efforts on a narrow band of patentable delivery platforms focused on differing delivery needs.

Some of the primary delivery platforms are categorized below:

Patient-friendly delivery systems (e.g., transdermal patches, transmucosal sprays, dissolvable films, and mini-tablets)

Needle-free delivery systems (e.g., coated tablets with tiny needles that are exposed in the gastrointestinal tract, microfluidic atomization, refillable sprayers, microneedle technology, and jet injectors)

Release delivery systems (e.g., immediate release [IR], controlled release [CR]pediatric and adult, and osmotic delivery)

Focused site delivery systems (e.g., focused ultrasound delivery, implantable pumps, and MRI-directed microbubbles)

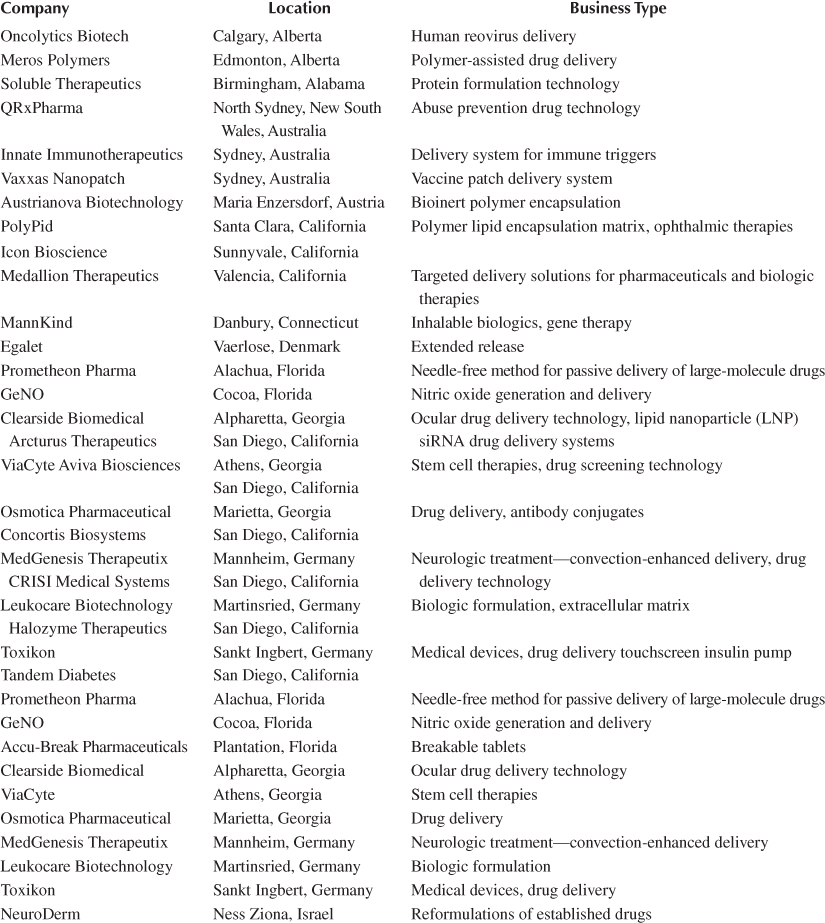

The following list of development organizations provides a sampling of the unique novel drug delivery companies that are currently striving to bring new solutions to the market, for either curing varied disease types or bringing improved efficacy to existing drug products. The major contributors to these novel drug delivery organizations are small, science-based companies, created and sustained by investors or major pharma funding to advance their research and clinical applications of their respective products. The scientific expertise of these companies grows as offshoots of major pharma organizations, where these novel approaches cannot be financially justified within the research and development programs focused on major drug programs for higher-volume drugs.

Edward J. Tannebaum has more than 45 years of experience as an architect, construction manager, and corporate facilities lead, primarily focused on the pharmaceutical industry. A graduate of the College of Architecture, Planning and Design at Kansas State University, Manhattan, Ed has been a lead figure in the design and construction of solid dosage facilities throughout the world. As the head of facility design and construction for Johnson & Johnson, McNeil Consumer Healthcare Division, he was responsible for the planning and execution of facilities, both domestically and abroad. His comprehension of the OSD business from the owners, designers, and constructors perspectives has provided him with a unique perspective into operational issues that are critical to address in these projects. His knowledge of domestic and international statutes and trends has become a larger and larger focus in recent years of consulting. As a senior principal of Integrated Project Services (IPS) for many years, he led design and build efforts and many conceptual design activities related to OSD and novel drug delivery facilities. For many years, he was a frequent speaker at International Society for Pharmaceutical Engineering educational programs related to design and project facilitation. His role as a principal of Strategic Planning Initiatives, LLC, provides him with a platform of expertise to continue assisting pharmaceutical management with strategic master planning to coincide with their business needs. Tannebaum was the author of the OSD chapter for the first edition of Good Design Practices and has provided input to bring the publication to its current level of information, authoring of this edition.

Font size:

Interval:

Bookmark:

Similar books «Good design practices for GMP pharmaceutical facilities»

Look at similar books to Good design practices for GMP pharmaceutical facilities. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Good design practices for GMP pharmaceutical facilities and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.