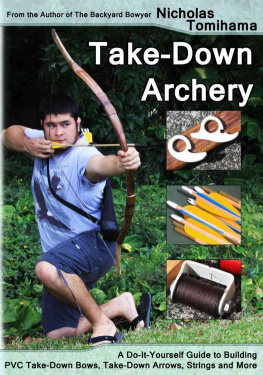

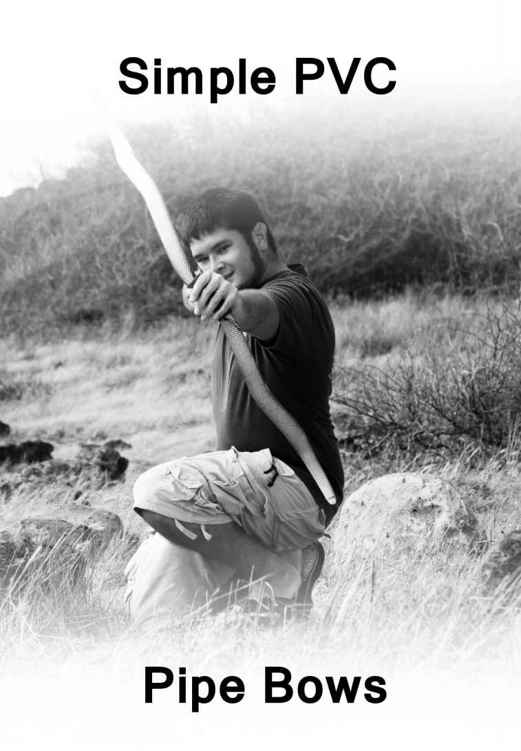

Simple PVC Pipe Bows

A Do-It-Yourself Guide to Forming PVC Pipe Into

Effective and Compact Archery Bows

Nicholas Tomihama

Simple PVC Pipe Bows

Levi Dream

Copyright 2012 Nicholas Tomihama

www.backyardbowyer.com

Printed in the United States of America

First Printing in 2012

All rights reserved. No part of this book may be reproduced in any form, by any means including but not limited to mechanical, photographic, or electronic process, or in the form of a phonographic recording, nor may it be stored in a retrieval system, transmitted, or otherwise be copied without permission from the publisher in writing.

This book is intended as an informational guide. The views expressed within are solely the opinions of the author, based on personal experience. All instructions within this book must be followed with caution, and the author, publisher, printer and all other parties involved deny any responsibility for injury to both body and property due to the misuse of information contained herein.

This book is a description of the process the author takes to make simple PVC pipe bows. The results portrayed in the book are as done by the author and are not indicative of work done by other individuals. While the informations is presented in a clear and concise manner, the author makes no guarantee that following the instruction will yield the same quality work. Nor does the author, publisher, printer and all other parties involved suggest following the instructions within as they carry risk inherent to all forms of archery and the bowyers craft.

Bows are inherently dangerous weapons and care must be taken during the use and manufacture of them. No bow is indestructible and every bow, regardless of strength can hurt, maim or kill. Never point a bow at another person, animal or into a place that may not be clear. Only use safe equipment when practicing archery. All minors must be supervised by a responsible adult.

For my God, my wife and my children.

Lifes blessings.

The Lord is good, a strong hold in

the day of trouble; and he knoweth

them that trust in him.

- Nahum 1 : 7

Words of Warning

Dear Reader,

Archery is an amazingly rewarding sport and for many including myself, a way of life. There are many ways to get into archery, many different styles of bow and many reasons to shoot. All aspects of archery should be respected and each is rewarding.

Within these pages you will find instructions and pictures showing how I build simple bows from PVC pipe. These bows are designed to be simple, utilizing only a single PVC pipe for a single bow. Yet while simple, they offer power and performance comparable to bows that require more work and equipment to build.

While PVC is more forgiving and more easily formed into an efficient working bow than any other material, the methods explained here are not automatic or effortless. A PVC bow requires your patience and respect, just like any other bow. Rushing into it, being ill prepared or skimping on methods may result in failure.

Before I immersed myself in building bows from PVC pipe, I shaped and crafted bows from single staves of wood, multiple laminations of wood and bows of wood and fiberglass. Even after building bows for years they arent easy. Sure it doesnt take nearly as much time and Ive developed a feel for them that makes the most tedious processes go quickly, but they arent easy to make in any way.

As a bowyer who has built hundreds of bows, I still have trouble making them all go the way I want all the time. My success rate isnt 100% and I dont think it ever will be. I work with several thousand dollars in equipment that makes building a bow in an hour possible. Yet add in the time it takes to let wood dry , glue to set, finish to cure and the constant adjustment required for each bow to reach maturity and it can takes months for a bow to go from raw wood to finished product.

As a beginner with few tools and no previous experience, it can take days if not weeks of work to reduce a stave into a working bow. The process of teaching wood to bend alone can take many hours of seemingly endless toil and adjustment. Its not difficult work and is definitely worth it, but it is strenuous and tedious work. Even after all this, a beginner with no formal instruction would be lucky to have a bow that shoots faster than 100 feet per second with a matched arrow.

Even after all the work I put into them, my selfbows dont regularly exceed 150 fps and the fastest bows barely exceed 170 fps. While some of my laminated bows do reach into the 200s, they are the exception rather than the rule. My first performance PVC bow, which took a few hours of shaping and tweaking before I had any experience with it and no guide on the subject existed, still to this day exceeds 140 fps with a matched arrow.

Over the last year I have received countless testimonial from happy owners of PVC bows they built with their own hands. It isnt easy but its doable and more accessible than virtually any other material for the beginner. With a little practice and patience, bows that rival even commercial bows in performance and speed are possible with few tools, PVC pipe and raw determination.

-Nick Tomihama

Table of Contents

Chapter One Getting Started

Welcome to Simple PVC Pipe Bows ! Thank you for joining me on this journey. Believe me, building bows from PVC pipe is truly a journey. This book is an introduction to a few of the many styles and performance levels of bow that can be made from PVC pipe. Lets start by getting familiar with the parts of a bow.

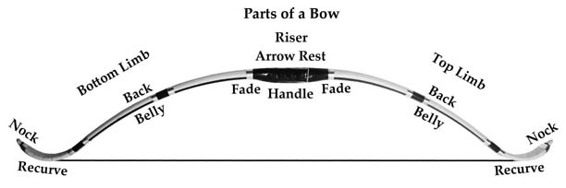

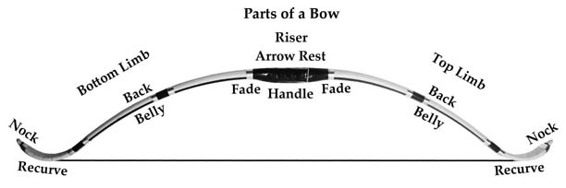

PVC Bow Anatomy

The bows we will be building are simple in their parts and function. To get an understanding of what a PVC bow is and how it works, well start with the basic parts of a bow.

A bow is broken into three main parts: the ends, limbs and riser. Starting from the outside of the bow, the nock is the area where the string connects to the bow. There are some variations on this, but the purpose of the nock is always the same. Further in are the bows recurves.

A recurve is a tip that curves away from the archer and has the string resting on it when the bow is strung up. Not all bows are recurved and not all recurves are equal. The bows in this book all have what are called static recurves, meaning the tips are stiff and dont flex while the bow is being drawn.

Further inward are the limbs. These make up the bulk of the bow and are the parts that do most if not all the work. There are two limbs, a top and bottom limb. The top limb is held upwards and the bottom limb is held downwards. The limbs, and the whole bow in general, is broken into two sides called the back and belly.

The back of the bow is the side of the bow that is away from the archer. This side of the bow is under a force known as tension. When the bow is strung and drawn back, it is this side that has to resist being torn apart as it is stretched outwards. PVC is very flexible and can resist tension unless the back is cut or brittle through burning or UV exposure.

The belly of the bow is the side that faces the archer. This side has to resist compression, a pushing force. When the bow is drawn, the belly is literally being crushed by the force of the bow pushing inwards. Since PVC is very dense, the belly can resist large amounts of compression unless there is an uneven spot or crease in the pipe.

The center section of the bow is called the riser. On either side of the riser is what is called the fades. These are the transition from riser to limb and like the name suggests, fade the limb into the riser. If the fades are creased or pinched, the riser could collapse.

Next page