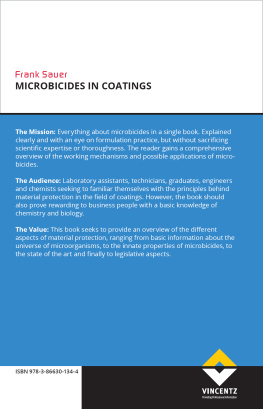

Bodo Mller

Understanding Additives

2nd Revised Edition

Cover: kwanchaift AdobeStock.com

Bibliographische Information der Deutschen Bibliothek

Die Deutsche Bibliothek verzeichnet diese Publikation in der Deutschen

Nationalbibliographie; detaillierte bibliographische Daten sind im Internet ber http://dnb.d-nb.de abrufbar.

Bodo Mller

Understanding Additives, 2nd Revised Edition

Hanover: Vincentz Network, 2019

European Coatings Library

ISBN 3-7486-0167-0

E-Book ISBN 978-3-7486-0168-5

2019 Vincentz Network GmbH & Co. KG, Hanover

Vincentz Network, Plathnerstr. 4c, 30175 Hanover, Germany

This work is copyrighted, including the individual contributions and figures.

Any usage outside the strict limits of copyright law without the consent of the publisher is prohibited and punishable by law. This especially pertains to reproduction, translation, microfilming and the storage and processing in electronic systems.

Discover further books from European Coatings Library at:

www.european-coatings.com/shop

Layout: Vincentz Network, Hanover, Germany

E-Book production: readbox publishing, Dortmund, www.readbox.net

Foreword

The author was not surprised by the success of the first edition, as there had not been a comparable textbook on the market that provided detailed explanations of paint additives. The author has therefore gladly taken on the task of revising and updating the first edition. To this end, he has eliminated errors, added several new figures and the completely new .

Additives are substances which are added to a coating composition in small amounts (commonly less than one percent) to alter the properties of a liquid paint or the resultant solid coating in a particular direction. For example, one property of a liquid paint is its ease of application, which can be influenced by rheological additives (e.g. sag control agents). One property of solid coatings is their anti-corrosion property, which can be influenced by corrosion protection additives or adhesion promoters. Additives act like medicines for paints and so can have unwanted side-effects as well.

The present book is primarily a textbook and originated from lectures given by the author at the University of Applied Sciences in Esslingen, Germany. Its objective is to provide a description of the chemistry and applications technology behind various paint additives. It does not cover test methods. On account of the sheer diversity of additives that exist, the book must further restrict itself to the most important types but it looks at these in detail. It also contains numerous photographs/diagrams to illustrate the various kinds of damage which additives prevent, as a picture says more than a thousand words. In specific cases, coatings formulations (starting formulations obtained from suppliers of raw materials) are presented to explain the specific use of an additive, thereby also illustrating the needs of the coatings industry.

Patent restrictions and registered trademarks (e.g. or ) are not mentioned explicitly. Product and trade names are only used where otherwise unavoidable. It should also be noted that product or trade names can change as a result of mergers and acquisitions. Nonetheless, most of the raw materials described herein or their equivalents are available worldwide.

The present textbook seeks to familiarise laboratory assistants, technicians, graduates, engineers, bachelors, masters and chemists with this class of raw materials for paints. It presupposes a basic knowledge of chemistry. Moreover, it will serve as a reference work for all readers interested in raw materials, paints and coatings.

Wrzburg, June 2019

Bodo Mller

Exclusion of liability

It should be noted that this book reflects the authors personal views, based upon his own knowledge. This does not absolve readers of the responsibility to perform their own tests with respect to the uses and applications of various processes or products described herein, and/or of obtaining additional advice regarding the same. Any liability of the author is excluded to the extent permitted by law, subject to legal interpretation.

Contents

Wetting and dispersing agents

1.1 Dispersing process

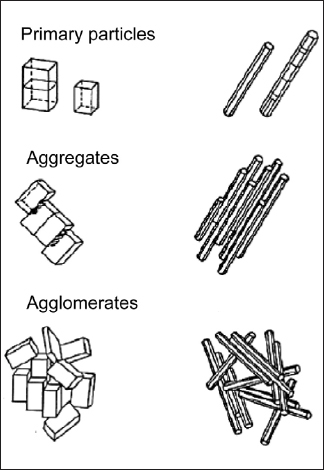

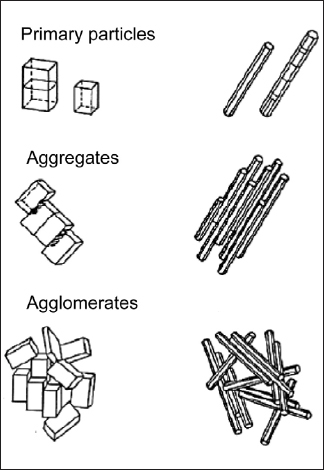

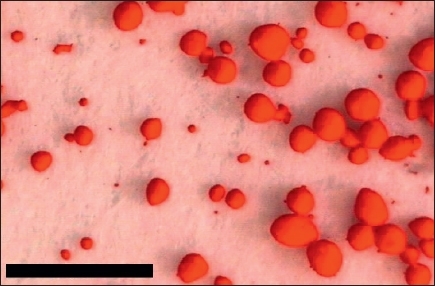

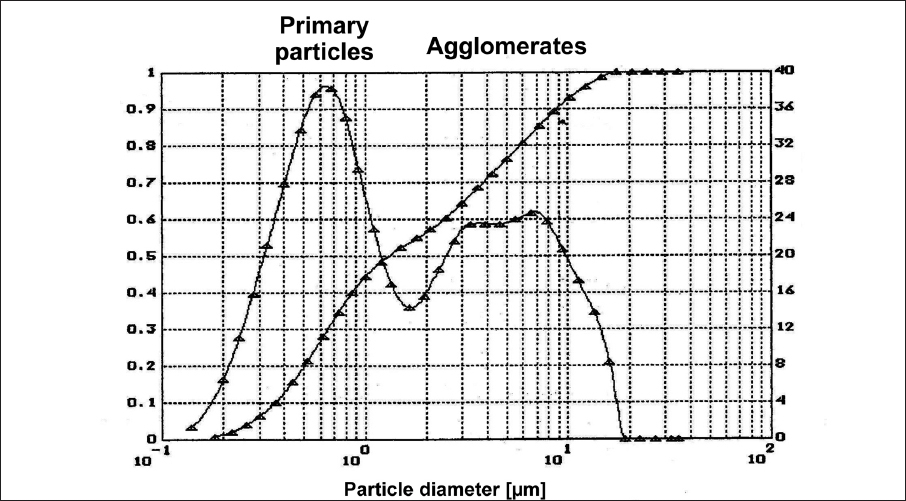

Before the dispersing process is discussed, it would be helpful to characterise pigment particles ().

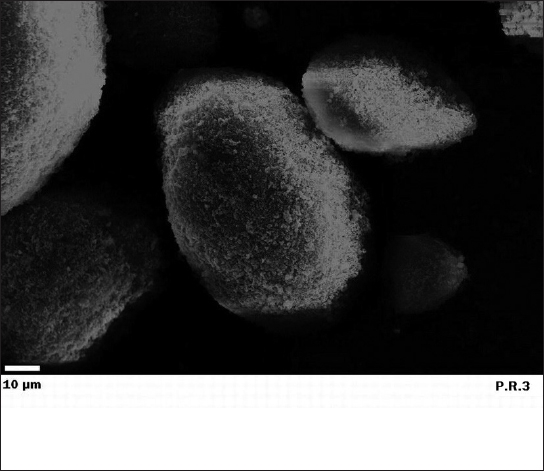

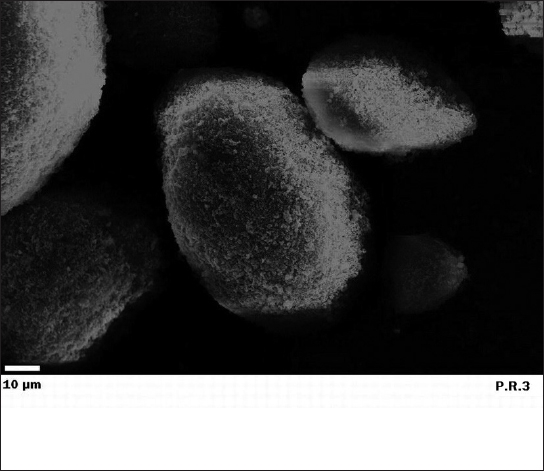

an optical micrograph of pigment Red 3 as a typical example of agglomerates of an organic coloured pigment. Grinding processes are classified as true size reduction (crushing of primary particles) and deagglomeration (grinding of agglomerates to yield aggregates and/or primary particles).

Figure 1.1: Simplified diagram of primary particles, aggregates and agglomerates

Figure 1.2: Scanning electron micrograph of pigment Red 3

In the coatings sector, dispersing or milling is taken to mean the homogeneous distribution of disperse solid particles (e.g. pigments) in a liquid medium (mostly a solution of binder), i.e. deagglomeration. As the dispersing of pigments is the most important step in paint manufacturing and is necessary for an understanding of dispersing agents, the underlying process will be discussed here briefly.

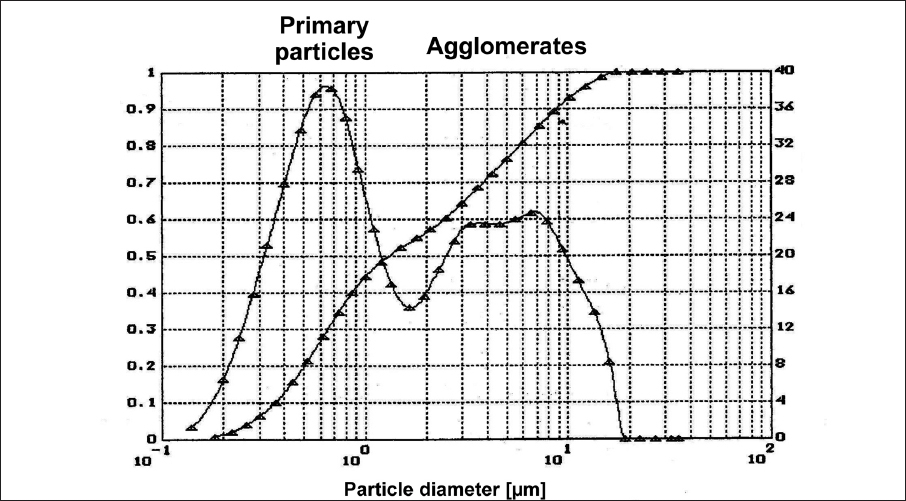

During dispersing, adhesive forces (e.g. van der Waals) acting between the pigment particles must be overcome[].

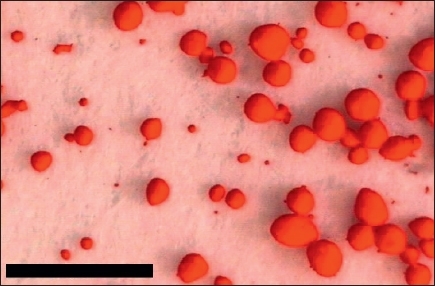

Figure 1.3: Optical micrograph of pigment Red 3 (scale bar 1 mm)

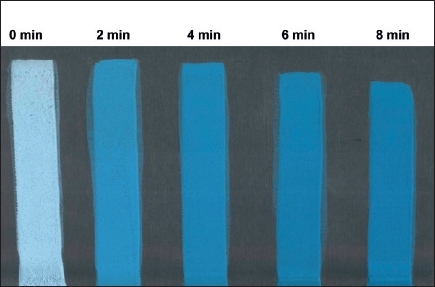

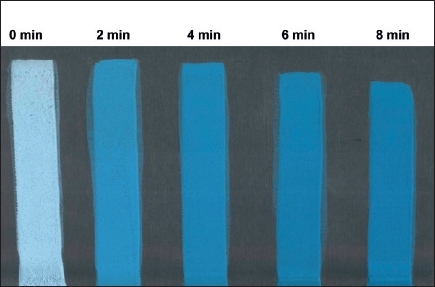

Figure 1.4: Coatings of pigment Blue 60 mixed with titanium dioxide after different dispersing periods in an aqueous latex gloss enamel (development of colour strength)

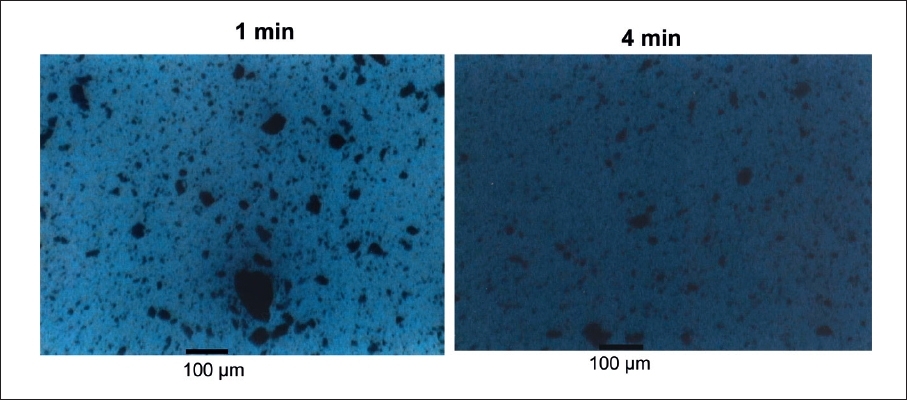

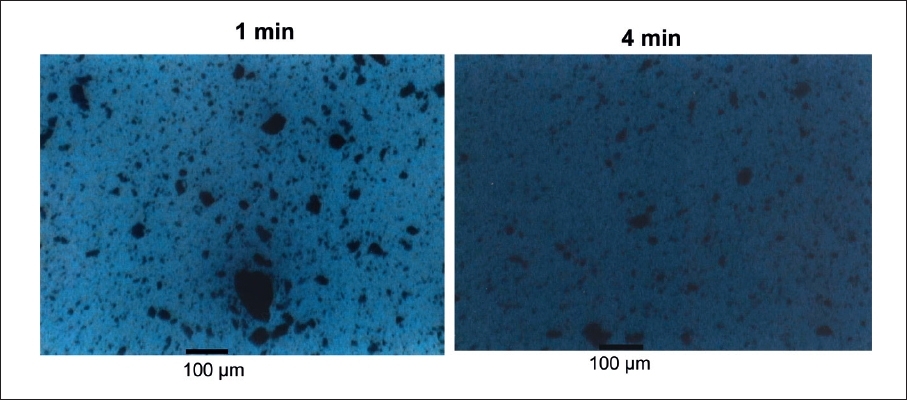

Figure 1.5: Optical micrographs (transmitted light) of a dispersion of phthalocyanine blue pigment after different dispersing periods

).

Dispersing proceeds in three steps:

Wetting of pigment agglomerates

Deagglomeration of pigment agglomerates

Stabilisation of the resulting dispersion against flocculation (see below).

Pigment agglomerates are wetted in two steps. The liquid phase spreads over their surface and then penetrates the pores or voids, displacing air.

Mechanical deagglomeration of the pigment agglomerates increases the tinting strength of coloured pigments () and renders them more economical.

shows optical micrographs (transmitted light) of a dispersion of phthalocyanine blue pigment after different dispersing periods; the qualitative decrease in agglomerate size is clearly evident.

Next page