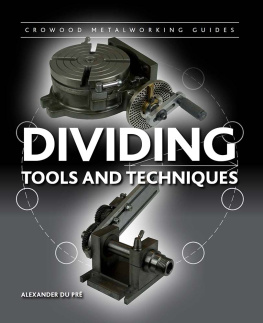

C R O W O O D M E T A L W O R K I N G G U I D E S

DIVIDING

Tools And Techniques

ALEXANDER DU PR

First published in 2014 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2015

The Crowood Press Ltd 2014

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 84797 839 4

Dedication

To Penny, Daniel and Philip.

Acknowledgements

I would like to offer sincere thanks to the following people who have helped with the preparation of this book. Kirk Burwell of Hemingway Kits (hemingwaykits.com) for dividing head photos; Lester Caine of Model Engineers Digital Workshop (medw.co.uk) for photos of the DivisionMaster; Dr Marcus Bowman and my uncle, Clive Elliott, for invaluable advice; and to my family for their support and understanding.

Disclaimer

Although every effort has been made to describe safe working practice and to supply accurate information in this book, neither the author nor the publisher accept any liability whatsoever for any loss or damage occasioned by the application or misapplication of the advice contained or implied or for any errors included.

Contents

1 Introduction to Dividing

SETTING THE SCENE

Imagine you are in your workshop. You have nearly finished machining a large casting involving several hours of careful work. Maybe it is a cylinder for a steam engine. The final job is to drill and tap a circle of bolt holes for the cover and a matching set of holes in the cover itself. You carefully mark out the positions of these holes in both parts before machining the holes. On completion you bring the two parts together only to find that the holes do not quite line up. The only solution is to drill the clearance holes slightly larger until the bolts can pass through and be tightened. At this point, you realize that the circle of holes is not quite centred in the right position. Whilst functional, the work is out of alignment and looks wrong. It ends up in the scrap bin.

This may be a familiar scenario to many inexperienced amateur machinists. The problems just described could have been avoided with the correct use of dividing techniques. The purpose of this book is to explain the theory and practice of dividing, which is perhaps one of the most commonly encountered machining operations after basic turning and milling work.

A typical home workshop garage conversion, equipped with lathes, a milling machine and a range of machine accessories and hand tools.

Since dividing work is so often needed, most metalworkers would consider it highly desirable to gain a good level of competence in dividing techniques and to equip themselves with at least some of the associated accessories.

This book is aimed at the amateur met-alworker keen to expand their repertoire of metalworking techniques and who may be on a limited budget but wanting to make the most out of a small collection of basic workshop machinery. It is envisaged that the reader will have access to a small home workshop, perhaps set up in a shed or garage and will have gained a basic competence in the use of the lathe and milling machine. It is hoped that model makers, model engineers, amateur machinists and anyone with an interest in metalwork will find this book of practical use and that it will help them to improve the quality of their work and the productivity of their time in the workshop.

DEFINITION OF DIVIDING

So, what is dividing and why is it useful? Dividing can be considered to be any operation where the objective is to machine equally spaced features, such as holes or gear teeth, around a circular path. These features are generally, but not necessarily, identical. They may be centred on the axis of a circular workpiece, or on any known point of an irregularly shaped workpiece.

Dividing may be approached in either of two ways, depending on the task in hand:

1. The workpiece is rotated about a given axis in equal increments whilst the cutting tool is held in the same position and moved across, or into, the workpiece, as in cutting spur gears. This is the technique used by dividing heads and similar devices that provide a means of accurately indexing the work.

2. The workpiece is fixed and the tool is moved around a circular path, as might be required when drilling a circular array of holes in a large casting, where it is not practicable to rotate the casting. This is the basis of the coordinate method, which can be used in circumstances where it is possible to control the position of the cutting tool accurately relative to the work.

Dividing is an essential technique for producing gears, ratchets, splines, dial graduations and similar items, or where equally spaced holes are required such as on pipe flanges, wheel hubs, brake discs, steam engine cylinders and any number of other applications. Whilst accurate dividing is generally made easier by using specialist accessories, there are often several ways of achieving the same results. This book will give you a range of options that will enable you to choose one that is most suitable for the job in hand and the equipment available, and hopefullyenable you to achieve the necessary results with minimum investment.

Dividing techniques were used to mill the spokes and drill the bolt holes on this model wheel.

Spur gears machined using a dividing head.

THE MATHS

This book aims to empower the reader by explaining the calculations supporting the various methods. Maths has only been included where essential, but some calculations are needed for the coordinate method and when calculating gear trains or working out dividing plate set-ups. Look-up tables have generally been avoided since they take up considerable space and do not make very interesting reading. Furthermore, it is difficult to make them relevant to your specific equipment due to the wide range of tooling available.

The maths involved is not particularly challenging but it can be rather repetitive. A calculator is essential, but a computer is even better if time is to be saved. The book is supported by the authors personal website, www.amdengineer.com, which provides some of the free electronic resources referred to in the text.

The operation of pitching out equally spaced, and indeed irregularly spaced features, in non-circular arrangements is sufficiently closely related to dividing to merit inclusion in this book. For this reason, the coordinate method is described in application to both dividing work and to machining more generally.

Next page