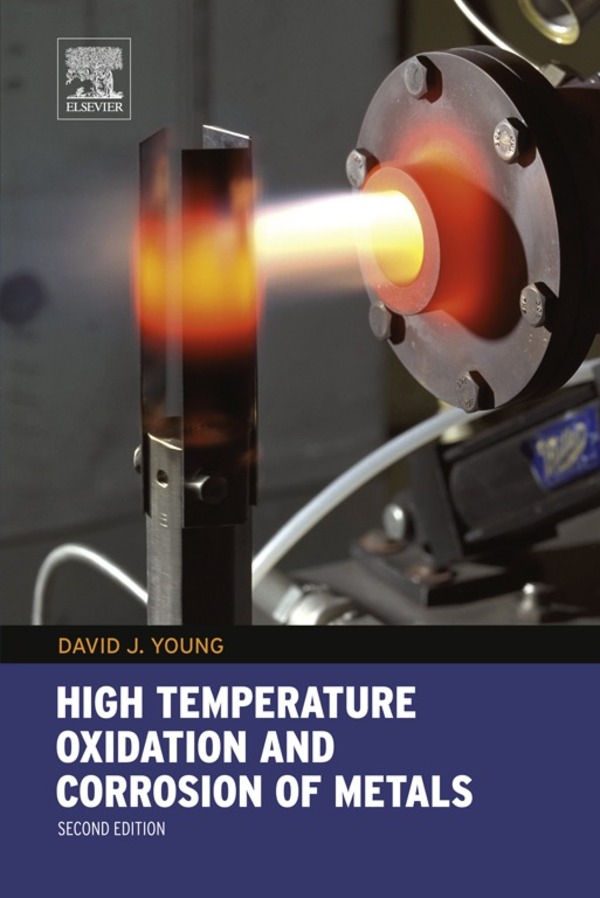

High Temperature Oxidation and Corrosion of Metals

Second Edition

David J. Young

School of Materials Science and Engineering, University of New South Wales, Sydney

Table of Contents

Copyright

Elsevier

Radarweg 29, PO Box 211, 1000 AE Amsterdam, Netherlands

The Boulevard, Langford Lane, Kidlington, Oxford OX5 1GB, UK

50 Hampshire Street, 5th Floor, Cambridge, MA 02139, USA

Copyright 2016, 2008 Elsevier Ltd. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher. Details on how to seek permission, further information about the Publishers permissions policies and our arrangements with organizations such as the Copyright Clearance Center and the Copyright Licensing Agency, can be found at our website: www.elsevier.com/permissions.

This book and the individual contributions contained in it are protected under copyright by the Publisher (other than as may be noted herein).

Notices

Knowledge and best practice in this field are constantly changing. As new research and experience broaden our understanding, changes in research methods, professional practices, or medical treatment may become necessary.

Practitioners and researchers must always rely on their own experience and knowledge in evaluating and using any information, methods, compounds, or experiments described herein. In using such information or methods they should be mindful of their own safety and the safety of others, including parties for whom they have a professional responsibility.

To the fullest extent of the law, neither the Publisher nor the authors, contributors, or editors, assume any liability for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions, or ideas contained in the material herein.

British Library Cataloguing in Publication Data

A catalogue record for this book is available from the British Library

Library of Congress Cataloging-in-Publication Data

A catalog record for this book is available from the Library of Congress

ISBN: 978-0-08-100101-1

For information on all Elsevier publications visit our website at https://www.elsevier.com/

Publisher: John Fedor

Acquisition Editor: Kostas Marinakis

Editorial Project Manager: Sarah Watson

Production Project Manager: Anitha Sivaraj

Designer: Maria Ines Cruz

Typeset by TNQ Books and Journals

Cover image: Burner rig tests in both heating and cooling positions thermal barrier coated super alloy hot. Courtesy of the National Aeronautics and Space Administration, John H. Glenn Research Center at Lewis Field (NASA Identifier GRC-C-1999-2487).

Foreword

The depletion of the first edition print run and an enormous increase in published research on high-temperature corrosion have combined to make a second edition of this book desirable. Recent work on mass transport in alumina and, more generally, on oxide grain boundary diffusion has contributed improved clarity to our understanding of how protective alumina and chromia scales behave. Similarly, new investigations into water vapour effects on scaling processes have expanded and refined our knowledge, although a simple, coherent picture remains elusive. These contributions, and several others, have been drawn upon in updating the original text.

Two new topics have been added, reflecting the large body of published research now available and the technological developments which drove that work. treats corrosion by carbon dioxide, an important issue if CO2 is to be captured from combustion gas streams. In addition, the thermal properties of carbon dioxide, along with its pressure-volume-temperature characteristics, make it attractive as a heat transfer and working fluid. For these reasons, it is a candidate for use in nuclear reactors and concentrated solar thermal power generation. Unfortunately, it is also corrosive to a variety of alloys.

A new , Corrosion in Complex Environments , is concerned with the corrosion phenomena arising from the presence of ionic melts and volatilising halides. Interest in these topics has arisen out of the much increased use of both biomass and municipal waste as fuels for thermal power generation. The resulting flue gases and deposits can be remarkably corrosive, and boiler operating temperatures are strictly limited as a result.

As in the first edition, I have tried to acknowledge important contributions to our understanding made by many researchers, and I apologise for any omissions. The second edition has benefited from colleagues around the world who have offered hospitality and/or generously gave expert commentary: Brian Gleeson (University of Pittsburgh), Daniel Monceau (INPT-CIRIMAT, Toulouse), Bruce Pint (Oak Ridge National Laboratory), Joe Quadakkers (Forschungszentrum, Jlich), Michael Schutze (Dechema, Frankfurt) and Jim Smialek (NASA, Lewis). Rectifying an important omission from the first edition, I thank my wife and family for their support and remarkable forbearance.

David J. Young

December 2015

Preface

Almost all metals and alloys of technological interest oxidise and corrode at high temperatures. However, the nature of their reaction products and the rates at which metal surfaces are degraded vary widely, and a capacity for prediction is highly desirable. This book is concerned with providing a fundamental basis for understanding the alloy-gas oxidation and corrosion reactions observed in practice and in the laboratory. Its purpose is to enable the prediction of reaction morphology, kinetics and rate as a function of temperature and the composition of both alloy and gas.

The term oxidation is used in a generic sense for any chemical reaction which increases the metal oxidation state by forming a compound such as an oxide, sulphide, carbide, etc. Alloy oxidation reactions can be conceived of as occurring in three stages. Initially, all reactive components of an alloy in contact with a hot gas are likely to react simultaneously. Subsequently, more thermodynamically stable compounds replace less stable ones, and a state of near equilibrium is locally approached. The reacting system can then be modelled as a series of spatially adjacent local equilibrium states which vary incrementally in reactant chemical potentials. During this stage, the reaction morphology and composition distribution are invariant with time. Ultimately, this steady state is lost, and all reactive alloy components are consumed in a final breakdown stage.

Successful alloys are those which evidence lengthy periods of slow, steady-state reaction. For this reason, considerable emphasis is placed on analysing the underlying local equilibrium condition and testing its applicability to particular metal or alloy-oxidant systems. When an alloy-gas reaction is at a steady state, the constant composition profile developed through the reaction zone can be mapped onto the relevant system phase diagram as a diffusion path. Frequent use is made of these paths in understanding reaction product distributions and in predicting, or at least rationalising, reaction outcomes.