Harald Anlauf - Wet Cake Filtration

Here you can read online Harald Anlauf - Wet Cake Filtration full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2019, publisher: John Wiley & Sons, Inc, genre: Children. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Wet Cake Filtration

- Author:

- Publisher:John Wiley & Sons, Inc

- Genre:

- Year:2019

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

- 60

- 1

- 2

- 3

- 4

- 5

Wet Cake Filtration: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Wet Cake Filtration" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

Wet Cake Filtration — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "Wet Cake Filtration" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

- Chapter 2

- Chapter 3

- Chapter 4

- Chapter 8

- Chapter 1

- Chapter 2

- Chapter 3

- Chapter 4

- Chapter 5

- Chapter 6

- Chapter 7

- Chapter 8

- Chapter 9

Harald Anlauf

Copyright

Author

Dr.Ing. Harald Anlauf

Karlsruhe Institute of Technology (KIT)

Institute of Mechanical Process

Engineering and Mechanics

Strae am Forum 8

76131 Karlsruhe

Germany

Cover

Courtesy of Bokela, Karlsruhe, Germany

and Dr. Harald Anlauf, KIT, Germany

All books published by WileyVCH are carefully produced. Nevertheless, authors, editors, and publisher do not warrant the information contained in these books, including this book, to be free of errors. Readers are advised to keep in mind that statements, data, illustrations, procedural details or other items may inadvertently be inaccurate.

Library of Congress Card No.:

applied for

British Library CataloguinginPublication Data

A catalogue record for this book is available from the British Library.

Bibliographic information published by

the Deutsche Nationalbibliothek

The Deutsche Nationalbibliothek lists this publication in the Deutsche Nationalbibliografie; detailed bibliographic data are available on the Internet at .

2019 WileyVCH Verlag GmbH & Co. KGaA, Boschstr. 12, 69469 Weinheim, Germany

All rights reserved (including those of translation into other languages). No part of this book may be reproduced in any form by photoprinting, microfilm, or any other means nor transmitted or translated into a machine language without written permission from the publishers. Registered names, trademarks, etc. used in this book, even when not specifically marked as such, are not to be considered unprotected by law.

Print ISBN: 9783527346066

ePDF ISBN: 9783527820634

ePub ISBN: 9783527820658

oBook ISBN: 9783527820665

Mechanical separation of particles from liquids represents a crosssectional technology, which touches nearly every industrial process, our personal life, and the environment. It is obvious that various physical separation principles and a huge variety of highly specialized apparatuses are needed to solve all separation problems in such different areas of application effectively and economically. Wet cake filtration, in contrast to dry cake filtration for gas cleaning purposes, represents one of the key technologies for solidliquid separation. This is particularly the case if deliquoring of the separated solid particles is an important issue.

This book should provide a comprehensive overview of more or less all relevant aspects of wet cake filtration. It represents one selected topic among others of the Karlsruhe School of SolidLiquidSeparation, which was founded in 1979 by Dr.Ing. Werner Stahl, Professor for Mechanical Process Engineering at the Technical University of Karlsruhe and refers to 40 years of research, development and teaching in this field. I myself had in 1979 the privilege to become the first PhD student of Stahl and to be part of this group for solidliquid separation until today under the present guidance of Prof. Dr.Ing. habil. Hermann Nirschl. This book is dedicated in great memory to Werner Stahl, who had strongly influenced the mechanical solidliquid separation technology in general by many innovative developments, which originated in an exceptionally creative atmosphere combined with accurate scientific work. One of his most important tasks was to shorten the gap between academia and industry and for every research project had to be considered not only the scientific attractiveness but also the prospective practical benefit. For this reason, special emphasis is placed in this book on the interdependence of theoretical fundamentals and practical applications.

Besides a detailed presentation of the cake filtration process itself and processrelated topics, such as slurry characterization or slurry pretreatment, special developments from the Karlsruhe School, such as Hyperbaric Filtration or Steam Pressure Filtration are included, which meanwhile worldwide have been established as the stateoftheart technology. In addition, promising new, but not jet, commercially available processes, such as Gasless Cake Desaturation or Shrinkage Crack Free Cake Desaturation are discussed to document the still ongoing evolutionary technical progress.

It would give me great pleasure if this book would support students and teachers from academia as well as engineers from the industry to deepen their knowledge about the physical background of the different cake filtration phenomena and to find out how the fundamentals can be used most effectively to solve practical solidliquid separation problems.

Karlsruhe, 2019

Harald Anlauf

Introduction and Overview

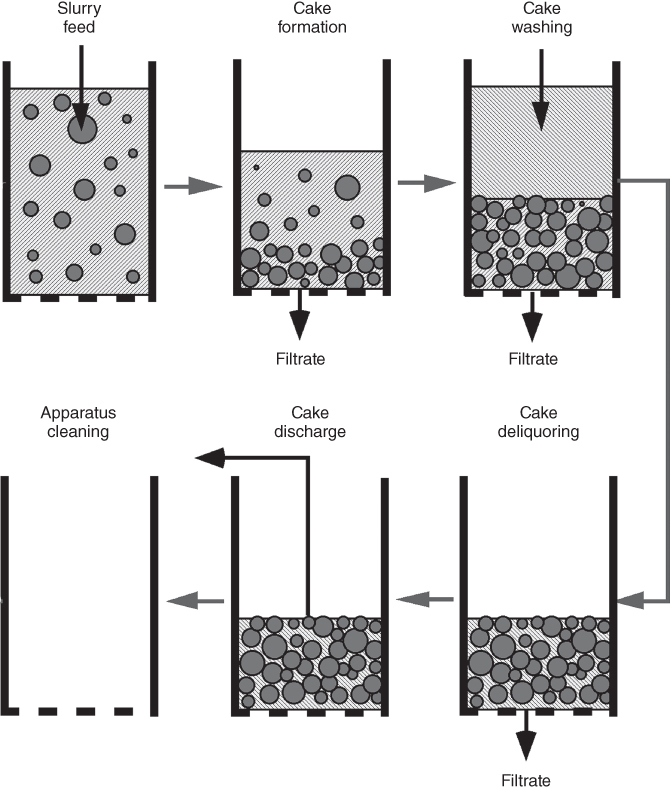

Cake filtration represents one of the several different mechanical methods to separate particles from liquids. Cake filtration offers, in comparison to other mechanical particleliquid separation techniques, the advantageous possibility of direct solids posttreatment. This enables particle washing by cake permeation and the comparatively lowest mechanically achievable solid moisture contents. Particularly, if low residual moisture content of the solids is an important issue, cake filtration is the preferred technique. Unfortunately, not in every case, cake filtration can be realized from the technical and/or physical point of view. shows the principal steps of a cake filtration cycle.

Process steps of a cake filtration.

After feeding the filter apparatus with slurry, a filter cake is formed under the influence of a pressure difference above and beneath the filter medium. If necessary, the cake can be washed in the next step to get rid of soluble substances in the liquid, which are still present in the wet cake. Finally, the filter cake is deliquored to displace further liquid from its porous structure. At the end of the process, the cake is discharged from the filter apparatus, and if necessary, the entire apparatus or the filter medium has to be cleaned.

The residual moisture content of the separated solids is considerably influencing the efficiency of a subsequent thermal drying and thus the energy consumption of the whole separation process. As a rule, the thermal methods are usually quite energyintensive compared with the mechanical liquid separation. In the literature, guiding numbers of more than factor 100 can be found between the energy demands of mechanical and thermal deliquoring []. In comparison to mechanical methods, thermal methods require not only heating of the wet system to the boiling point of the liquid but also a phase transition from the liquid to the gaseous aggregate state. The appropriate vaporization enthalpy must be raised. For this reason and also because of the oftenundesirable load of temperaturesensitive products, it is in most cases advantageous to separate as much liquid as possible at low temperatures by mechanical means. For physical reasons, a final rest of liquid remains in any case after the mechanical liquid separation in the particle structure. However, this portion of liquid can only be removed from the solid material by thermal means. If a completely dry powder is required as the final product, one of the tasks for the optimization of the whole separation process consists in determining the most favorable point of transfer from the mechanical to the thermal separation step. This interconnection point is very variable and defined by the requirements of the selected thermal drying process. For spray drying, a pumpable and sprayable slurry is still required, whereas the solids should be deliquored to the mechanical limit for a fluidized bed drying because the cake behaves brittle and powdery in that case. At the interface of these two basic processes for solidliquid separation, combined mechanicalthermal processes have also been developed and established such as centrifuge dryers, nutsche dryers, and in recent times continuously operating steam pressure filters. The advantages of these systems consist in synergies, which result in energy conservation and compact and simplified process design.

Next pageFont size:

Interval:

Bookmark:

Similar books «Wet Cake Filtration»

Look at similar books to Wet Cake Filtration. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book Wet Cake Filtration and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.