The Ultimate Skill-Building Guide. Renovate Your Home With Simple DIY Wood Furniture Projects and Ideas You Can Easily Replicate to Add a Unique Touch to Your Home

INTRODUCTION

Wood was one of the primary materials worked by early humans, with stones, clay, and animal limbs. A microscopic analysis of the Mousterian stone tools employed by Neanderthals suggests that there were plenty of habitats for woodworking. The phenomenon of civilization was closely tied to a greater degree of skill in making these materials work.

Wood was one of the primary materials worked by early humans, with stones, clay, and animal limbs. A microscopic analysis of the Mousterian stone tools employed by Neanderthals suggests that there were plenty of habitats for woodworking. The phenomenon of civilization was closely tied to a greater degree of skill in making these materials work.

Among the earliest names of woodworking tools are poles worked from Kalama Falls, Clacton-on-Sea, and Leiningen. The spears of Schengen (Germany) provide several primary specimens of wooden hunting gear. Flint tools were used for carving. Since the Neolithic period, carved wooden vessels have been known, for example, from the Linear Pottery culture wells at Korhonen and Nethra.

Examples of Bronze Age wood carvings include tree trunks and wooden folding chairs used in coffins in northern Germany and Denmark.

Location in Germany has provided specimens of wooden animal figurines from the Iron Age. Wood sculptures of the La Tne period are known from a sanctuary at the source of the Seine in France.

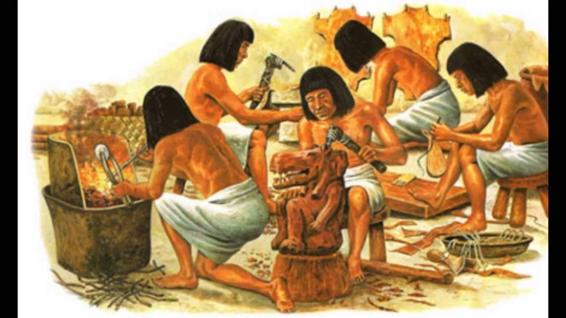

Egypt ancient

There is significant evidence of advanced woodwork. Woodwork is depicted in many famous ancient Egyptian paintings, and a substantial amount of antique Egyptian furniture (such as stools, chairs, tables, beds, chests) is preserved. The mausoleums represent an outer collection of those artifacts, and so the internal coffins found within the tombs were also built from wood. The metal employed initially by the Egyptians for woodworking tools was copper and, finally, ironworking after the bronze was unknown until 2000 BC.

Commonly used wooden tools included ax, skit, chisel, saw, and bow drill. Mortise and tenon joints are evidenced by the early predynastic period. These joints were strengthened using pegs, dowels, and leather or cord lashing. The glue was to be used only within the New Kingdom period. The ancient Egyptians invented the art of finishing and used varnish for finishing, although the composition of those varnishes is unknown. Although various native acacias were used, as wood was produced from the local sycamore and tamarind trees, deforestation within the Nile resulted in timber imports, notably cedar, but alfredo pine, boxwood, and Oak also, other than dynasty.

With the advancement in modern technology and hence the industry's demand, woodworking as a field has changed. For example, the phenomenon of computer numeric controlled (CNC) machines has prepared us to mass-produce and reproduce with less waste, and sometimes in more complex designs than ever before. CNC wood routers can create complex and highly detailed shapes in flat stock to make signs or art. Rechargeable power tools accelerate the construction of many projects and require much less body strength than within the past, for example, when many holes are boring. The skilled logger, however, remains a craft pursued by many. Handcrafted work such as furniture and humanities remains in demand, although with the rate and price of production, the value for consumers is far greater.

Historically, woodworkers depended on the forest native to their region until transportation and trade innovations provided more exotic wood to the craftsman. Wood is typically sorted into three basic types: hardwoods typified by hard grain and obtained from broad trees, softwood from coniferous trees, and human-made materials such as plywood and MDF.

Hardwoods botanically referred to as angiosperms, are deciduous and shed their leaves annually with temperature changes. Softwoods come from trees that are botanically referred to as coniferous gymnosperms cone-bearing and live green year-round. Although a familiar pattern, softwoods are not always "softer" than hardwoods, and in another way.

Softwood is most found within areas of the planet and is generally less durable, is lighter in weight, and is more susceptible to pests and fungal attacks than hardwood. They typically have a paler color and more exposed grain than hardwood, which contributes to the tendency of softwoods to fall and fall as it dries. Softwoods usually have lower densities, around 432592 kg / m, which can compromise their strength. Thickness, however, varies within both softwoods and hardwoods, counted on the geographic origin of the wood and the rate of growth. However, the low density of softwoods also allows it to hold more strength with lighter weight. Within the US, softwoods are generally cheaper and more readily available, and accessible. Most softwoods are suitable for general construction, particularly framing, trim and finish work, and carcass vehicles.

Hardwoods are divided into two categories, temperate and tropical hardwoods, counted at their origin. Soft hardwoods are found in the tropics and areas between poles and are of particular interest to woodworkers for their cost-effective aesthetic appeal and permanent sources. Tropical hardwoods are located within the equatorial belt, including Africa, Asia, and South America. Hardwoods flow to a better density, resulting in a slower growth rate of about 1041 kg / m, and are more stable upon drying. As a result of its high density, hardwoods are generally heavier than softwoods but may also be more brittle. While there are many hardwood species, only 200 are sufficient and usable enough for woodworking. Hardwoods have an excellent variety of properties, making it easy to search for hardwoods for almost any purpose. Still, they are particularly suitable for outdoor use due to their strength and resilience to rot and decay. The color of hardwood varies from light to very deep, making it exceptionally versatile for aesthetic purposes. However, because hardwoods are more closely granular, they are generally more challenging to find than softwoods. They are also harder to deposit within the US and, as a result, are more expensive.

Furniture, usually like tables and chairs, is made using solid stock from hardwoods, thanks to its strength and resistance to wear. Additionally, they have an excellent grain pattern and color, and finishes allow the woodworker a great deal of artistic freedom. Hardwoods are often cut more cleanly and leave less residue on saws and other woodworking tools. Cabinet/fixture manufacturers employ the use of plywood and other artificial panel products. Like the Windsor Chair, some furniture has greenwood, shaped like wood, while having natural moisture before drying.

Although many kinds of wood are often used for carving, some are the obvious favorites, including aspen, basswood, butternut, black walnut, and oak. Because it is almost no grain and is exceptionally soft, basswoods are an incredibly fashionable beginner. It is used in many low-cost instruments such as guitars and electric basses. Aspen is equally quiet, though a bit tough, and is readily available and inexpensive. Butternut is much darker than basswood and aspen and has a fine grain that is easy to carve and thus suited to beginners. It is also suitable for furniture. While expensive compared to basswood, aspen, and butternut, black walnuts can be a popular choice for their rich color and grain. Lastly, oak can be a healthy, strong, and versatile wood for carving with the mentioned grain. It is also a well-liked wood for furniture making.

Wood was one of the primary materials worked by early humans, with stones, clay, and animal limbs. A microscopic analysis of the Mousterian stone tools employed by Neanderthals suggests that there were plenty of habitats for woodworking. The phenomenon of civilization was closely tied to a greater degree of skill in making these materials work.

Wood was one of the primary materials worked by early humans, with stones, clay, and animal limbs. A microscopic analysis of the Mousterian stone tools employed by Neanderthals suggests that there were plenty of habitats for woodworking. The phenomenon of civilization was closely tied to a greater degree of skill in making these materials work.