IEEE Press

445 Hoes Lane

Piscataway, NJ 08854

IEEE Press Editorial Board

Lajos Hanzo, Editor in Chief

| R. Abari | M. El-Hawary | S. Nahavandi |

| J. Anderson | B. M. Hammerli | W. Reeve |

| F. Canavero | M. Lanzerotti | T. Samad |

| T. G. Croda | O. Malik | G. Zobrist |

Kenneth Moore, Director of IEEE Book and Information Services (BIS)

Copyright 2011 the Institute of Electrical and Electronics Engineers, Inc. All rights reserved.

Published by John Wiley & Sons, Inc., Hoboken, New Jersey

Published simultaneously in Canada

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per-copy fee to the Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 750-4470, or on the web at www.copyright.com. Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748-6011, fax (201) 748-6008, or online at http://www.wiley.com/go/permissions.

Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts in preparing this book, they make no representations or warranties with respect to the accuracy or completeness of the contents of this book and specifically disclaim any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives or written sales materials. The advice and strategies contained herein may not be suitable for your situation. You should consult with a professional where appropriate. Neither the publisher nor author shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

For general information on our other products and services or for technical support, please contact our Customer Care Department within the United States at (800) 762-2974, outside the United States at (317) 572-3993 or fax (317) 572-4002.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic formats. For more information about Wiley products, visit our web site at www.wiley.com.

Library of Congress Cataloging-in-Publication Data:

Lenk, Ron, 1958

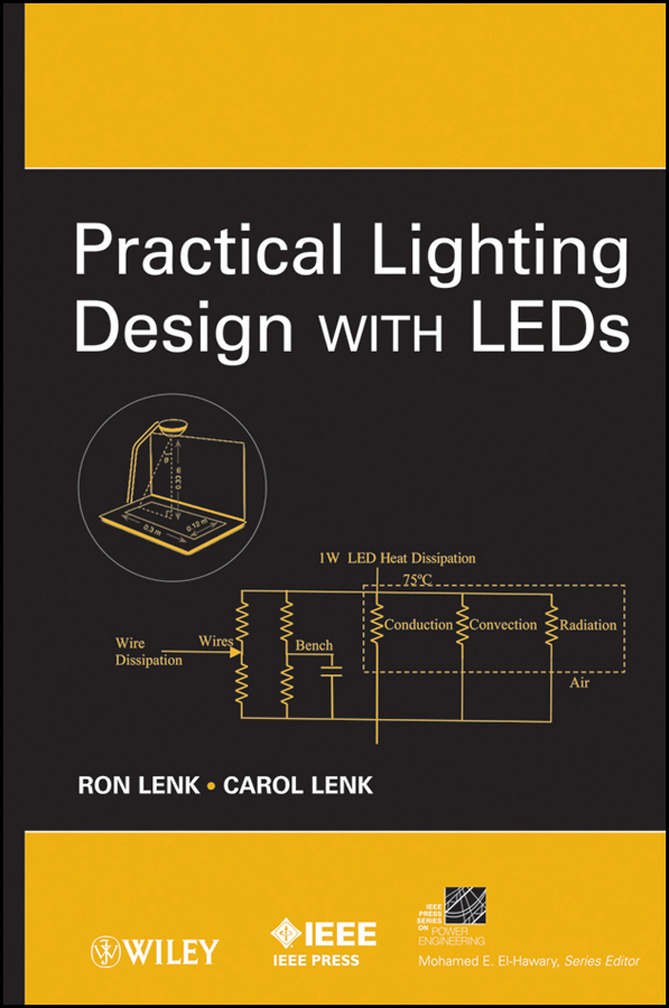

Practical lighting design with LEDs / by Ron Lenk, Carol Lenk.

p. cm. (IEEE Press series on power engineering ; 67)

ISBN 978-0-470-61279-8

1. Light emitting diodes. 2. Electric lampsDesign and construction. 3. Electric lightingDesign. I. Lenk, Carol. II. Title.

TK7871.89.L53L46 2011

621.32dc22

2010048267

oBook ISBN: 978-1-118-00821-8

ePDF ISBN: 978-1-118-00820-1

ePub ISBN: 978-1-118-01173-7

To our children, for being so patient

Figures

Figure 1.1 T1 (5 mm) LEDs

Figure 1.2 Fluorescent Tubes Spectral Power Distribution

Figure 1.3 LEDs Can Be Used Everywhere

Figure 1.4 Haitzs Law

Figure 2.1 Currents in a Fluorescent Tube

Figure 2.2 Various Bulb Shapes

Figure 3.1 The Electromagnetic Spectrum

Figure 3.2 Scotopic Vision is much more Sensitive than Photopic Vision

Figure 3.3 Emission Spectra of Four Common Light Sources

Figure 3.4 Solar Radiation Spectrum

Figure 3.5 One Steradian Intersects 1 m2 of Area of a 1 m Radius Ball

Figure 3.6 Solid Angle in Steradians versus Half Beam Angle in Degrees

Figure 3.7 Definition of Beam Angle

Figure 3.8 Typical Lambertian Radiation Pattern

Figure 3.9 Dimensions for a USB Keyboard Light Design

Figure 3.10 Spectra of Neutral-White and Warm-White LEDs

Figure 3.11 CIE 1931 ( x , y ) Chromaticity Space, Showing the Planck Line and Lines of Constant CCT

Figure 3.12 ( x , y ) Chromaticity Diagram Showing CCT and 7-Step MacAdam Ellipses

Figure 3.13 Cool White Fluorescent 4100 K, CRI 60; Incandescent, 2800 K, CRI 100; Reveal Incandescent 2800 K, CRI 78

Figure 3.14 Approximate Munsell Test Color Samples

Figure 3.15 Circadian Rhythm Sensitivity

Figure 3.16 Identical Gray Boxes Look Different Depending on Their Background

Figure 4.1 Reverse Bias Protection

Figure 4.2 LEDs with Reverse Bias Protection

Figure 4.3 Light Output as a Function of Current

Figure 4.4 Forward Voltage as a Function of Current

Figure 4.5 Efficacy versus Drive Current

Figure 4.6 Light Output as a Function of Wavelength

Figure 4.7 Many LEDs Have Poor R9

Figure 4.8 ( x , y ) as a Function of Current

Figure 4.9 Different Output Light Distributions Are Available

Figure 4.10 Neutral-White Bin Structure

Figure 5.1 Brightness as a Function of Temperature

Figure 5.2 LED Temperature Profile for Parameters Given in Text

Figure 5.3 Forward Voltage as a Function of Current

Figure 6.1 Thermal Model for LED Example

Figure 6.2 Thermal Model of Two Parallel Thermal Paths

Figure 6.3 LED Temperature as a Function of Time

Figure 6.4 There Are Many Thermal Paths to Ambient

Figure 6.5 Estimating Temperature Rise from Power Density

Figure 6.6 An LED Heat Sink

Figure 7.1 12 V Battery I-V Curve

Figure 7.2 Alkaline-Cell Battery Voltage as a Function of Time with a Resistive Load

Figure 7.3 Operating a Transistor in Linear Mode Is Inefficient

Figure 7.4 When the Transistor Is On, Current in the Inductor Increases; When the Transistor Is Off, Current in the Inductor Decreases

Figure 7.5 LM3405 Schematic for Buck

Figure 7.6 FAN5333A Schematic for Boost

Figure 7.7 HV9910 Schematic for Buck-Boost

Figure 7.8 Pulse Width Modulation Turns the Current Rapidly On and Off to Get an Average Current

Figure 7.9 Dimming Circuit

Figure 7.10 The Effect of the Current Sense Resistor Is Compensated by Putting One in Series with Each String

Figure 7.11 LED Forward Voltage Variation Can Be Compensated at the Cost of Additional Power

Figure 7.12 Ballasting LED Strings with Total Current Sensing

Figure 8.1 Block Diagram of AC SMPS for LED Lighting

Figure 8.2 A Bridge Rectifier

Figure 8.3 Half-wave Rectification

Figure 8.4 Reducing the Ripple from a Bridge Rectifier with a Capacitor

Figure 8.5 Running LEDs Directly Off-Line

Figure 8.6 How the Off-Line Buck Works

Figure 8.7 A Nonisolated Off-Line LED Driver

Figure 8.8 Adding a Transformer Makes the Converter into a Forward

Figure 8.9 Adding a Transformer Makes the Converter into a Flyback

Figure 8.10 Protecting the HV9910 from High Voltages

Figure 8.11 Resistors Balance Voltages for Series Capacitors

Figure 8.12 Normal Mode EMI Filtering for a Two-Wire Input

Figure 8.13 Common Mode EMI Filtering Added for a Three-Wire Input

Figure 8.14 Current Loops May Cause EMI Problems; Reducing Loop Area Helps

Figure 8.15 A Big Capacitor Maintains Constant Voltage During the Line Cycle, Generating Large Peak Currents and Bad Power Factor

Figure 8.16 A Smaller and Cheaper PFC

Figure 8.17 Simple Power Factor Correction Circuit

Figure 8.18 Adding an MOV to the Design Protects It Moderately Well from Lightning