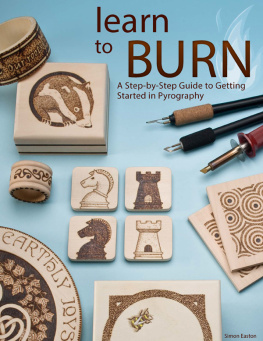

Pyrography: The Art of Woodburning

Rebecca Bell

Published by Rebecca Bell, 2021.

While every precaution has been taken in the preparation of this book, the publisher assumes no responsibility for errors or omissions, or for damages resulting from the use of the information contained herein.

PYROGRAPHY: THE ART OF WOODBURNING

First edition. December 28, 2021.

Copyright 2021 Rebecca Bell.

ISBN: 979-8201432768

Written by Rebecca Bell.

10 9 8 7 6 5 4 3 2 1

PYROGRAPHY

The Art Of Woodburning

By

Rebecca Bell

CONTENT

I f you decide to master the art of pyrography - wood burning, this book is for you. The properties of wood, methods of preparing the material, the necessary tools, and devices, basic techniques of burning, methods of finishing, finished products, clear illustrations. The book will be useful not only for beginners but also for experienced craftsmen.

A BRIEF HISTORY OF PYROGRAPHY

W oodburning, or pyrography , has been practiced by people for over a thousand years. The first items decorated with a scorched pattern were found in Peru and date back to 700 BC. e. Scratchingcharred wood is a tool ancient artists discovered that wood is an excellent material for painting and this property can be used for decorative purposes. First, the wood is burned to help open fire, later began to use hot nails, metal rods that were sharpened at a specific angle. The term "pyrography" itself appeared in England during the Victorian era. It comes from the Greek words , which means "fire", and , which means "to write."

In the 17th century, woodburning became a very common artistic craft in Europe. Craftsmen decorated with patterns mainly household items made of wood - spoons, candlesticks, etc., later furniture decorated with burning became popular. Ornaments for pyrography were used traditionally, the same with which silver utensils were decorated or clothes of those times were embroidered.

In the 19th century, the professionalism of pyromasters increased significantly. However, pyrography had not yet become a commercial craft and wood burning was done more for their pleasure. Part of the reason for this was the lack of special tools that allowed the craftsman to work quickly. A typical pyrography toolbox consisted of a portable pot or brazier with holes along the top edge and a stoker. Through the holes, pokers were inserted into a brazier, where they were heated on hot charcoal. At the same time, a special pointed tip was put on the poker. Usually, the master had several of these tips of various shapes. The handle of the pyromaster's poker was covered with asbestos so that it could be held without scalding.

With a poker just removed from the brazier, the master burned out areas where the greatest clarity and depth of lines were required, gradually moving to places where less noticeable lines were supposed. To work on a large work, the master needed an assistant to carry the poker from the workplace to the brazier and vice versa. At the same time, despite the imperfection and high temperature of the tools, some pyromasters managed to achieve an amazingly high quality of work.

Towards the end of the Victorian era, gas and electric ovens and burners, as well as platinum-tipped pokers, came to the aid of craftsmen. In addition to the poker, for burning wood, for example, a combustible gas mixture fed through a tube began to be used. It was used to obtain light firing. They also used a kind of "burning machine, working on the principle of a volcano." This machine consisted of a can, similar to a large modern aerosol can, to which a rubber tube and bellows were attached to inject air from two adjacent rubber containers. The balloon was filled with gasoline or alcohol. The vapors of the combustible liquid were pumped into a rubber tube with a platinum tip and ignited as they passed through it. A whole set of tips of various shapes was attached to the machine, which could be replaced if necessary. To maintain a constant glow of the platinum needle, the master had to periodically pump gasoline with a foot pedal. When working with such a machine, it was always necessary to have a small container of nitric acid on hand to remove the scale formed on the tip. Of course, such a craft could not be useful for health. But, despite all the difficulties, pyrography continued to develop.

At the end of the 19th century, the first Russian nesting doll was made in the "Children's Education" workshop in Moscow, based on a sketch by the famous artist Sergei Malyutin. All eight figures of this nesting doll were covered with a scorching pattern. Burning wood in the Russian Empire was at that time a relatively new and uncommon method of artistic woodworking.

At the beginning of the twentieth century, salt shakers, glasses, ladles, boxes, caskets, etc. began to be decorated with scorched patterns. In 1912, about a hundred families were engaged in burning and painting in Sergiev Posad near Moscow. Many different versions of nesting dolls have been developed. However, the high demand for nesting dolls forced the craftsmen to abandon labor-intensive pyrography, and gradually burning was replaced by painting. But to decorate wooden boxes, caskets, caskets, they continued to use this method of decorative design. On their covers, scenes from folk life, events of history, cities were depicted. A significant part of the items was decorated with various patterns. Other household items were not ignored either.

In the XX century, all of the above tools were replaced by a new pyrographic device, which was based on the design of a soldering iron. It was a colossal step forward. Such a device is still used by some pyromasters, despite its cumbersomeness and the fact that with prolonged use, its handle heats up to such an extent that it becomes impossible to hold it.

The art continued to develop, and in 1962 Roy Child, son of the English wood turner Peter Child, decided to improve this device. A fifteen-year-old boy has developed a new design of the burning part of the device and practically eliminated the above disadvantages. By 1973, the industrial production of pyrographs, burning with a hot wire, was launched. This device is currently being improved. The specially shaped wire tip fits into the stainless steel holders, which together minimize the heating of the handle.