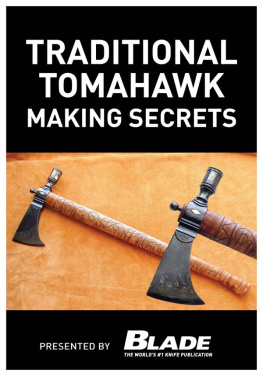

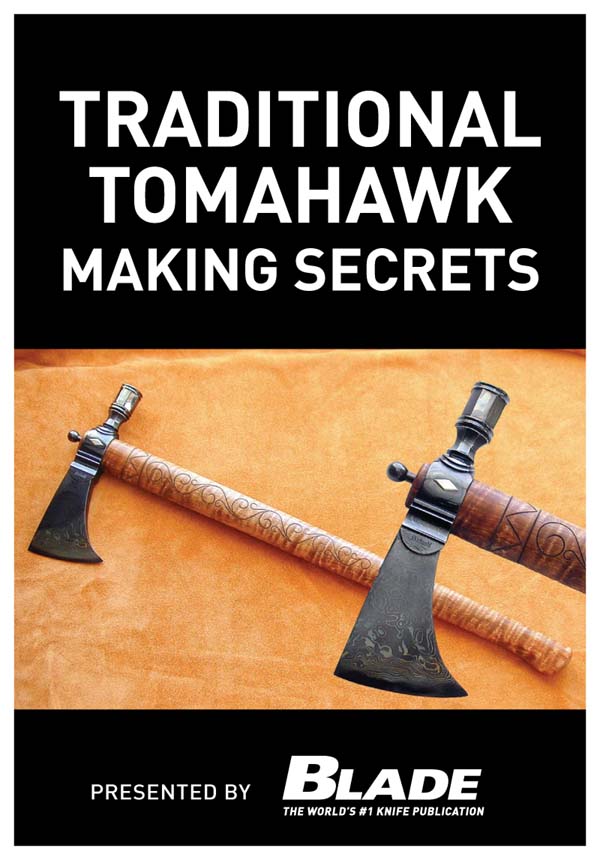

Traditional Tomahawk Making Secrets

LEARN HOW AMERICAN INDIANS AND EARLY BLADE SMITHS FASHIONED THE FIERCE AND FANTASTIC TOMAHAWK

BY JOE SZILASKI

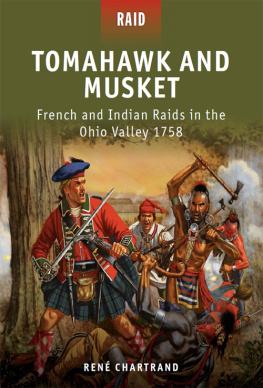

The tomahawk the author made in the working instruction for this chapter is based on a well-photographed piece dating back to 1793. It belonged to a Lieutenant Duke and featured a multi-faceted bowl with double chevrons. The eye (where the haft goes through the head of the tomahawk) had raised diamond-shaped silver overlays. The blade was engraved, and it sported a nicely carved ash haft.

You might remember seeing a similar tomahawk in the movie The Patriot, starring Mel Gibson. The prop used in that movie was also based on the 1793 tomahawk the author reproduced. This is the authors version.

Ever since seeing my first cowboy and Indian movie, I have been fascinated by tomahawks, as were most kids back in those days. The first time I saw an Indian tomahawk in person was when a Wild West show came to my small town.

In the 1960s I learned blacksmithing at a trade school in Hungary. I was one of the lucky ones who had the opportunity to learn from more than one master of the trade. My first master taught me how to make knives, cleavers and hatchets. After learning to fashion those tools, I had the chance to fulfill my lifelong dream of making a tomahawk.

I am still fascinated by tomahawks and their history. Though most of the hawks I now make are one-of-a- kind, presentation-quality pieces, they are all fully hardened, balanced, functional tools and weapons. I blend traditional and modern methods of building tomahawks.

The basic form of the tomahawk is a hatchet, and its one of the most perfect designs mankind has ever developed. Today we are able to reach the moon but we still use hatchets. In some parts of the country, hatchets are employed as a part of everyday life and the tomahawk still has its place in modern warfare.

The hawk I make for you here is based on a well-photographed piece dating back to 1793. It belonged to a Lieutenant Duke and featured a multi-faceted bowl with double chevrons. The eye (where the haft goes through the head of the tomahawk) had raised diamond-shaped silver overlays. The blade was engraved, and it sported a nicely carved ash haft. You may remember seeing a similar hawk in the movie The Patriot, starring Mel Gibson. The prop used in that movie was also based on this period piece.

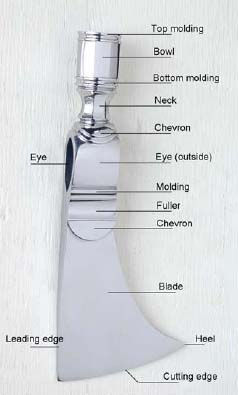

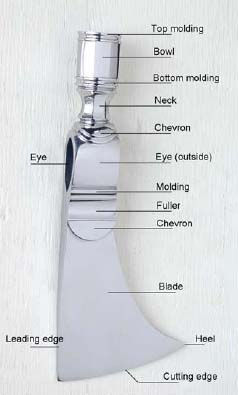

These terms are generally used to describe the parts of a tomahawk head, and by providing them, the author makes understanding the hawk-building process easier.

I have made several tomahawks over the years that were similar to the amazing 1793 model. The working piece for this instructional will be forged of random-pattern damascus, and it will fill a custom order from a collector. I am not aware of any tomahawks from that time period being made of damascus but that does not mean there weren't any.

Since this hawk head is forged from damascus, some of the steps I take in its formation stray from those used in fashioning traditional, non-damascus tomahawks. Instead of piercing the eye, I drill and file it to shape. Rather than using fuller tools to reduce the size of the neck and the blade section under the eye, I grind and file them. While the fullering is easier and offers more of a time savings, the grinding and filing will change the original damascus pattern, creating nice, visually appealing contrast.

This particular hawk, no matter what steel it is fashioned from, requires a lot of handwork. After forging the damascus billet, the head will be hand forged to shape. The details of the head will be hand filed into the steel, and the haft will be hand fitted and carved. I do make use of some power tools that would not have been available to the original smith back in 1793, but this does not eliminate the days of handwork.

In preparing a damascus billet, the author prefers to employ high-carbon steels like 1095 and 15N20. He says there is enough of a difference in carbon and chemical content between them to result in nice contrast in the damascus pattern.

PREPARING THE BILLET

The first step in making the project tomahawk is to prepare the billet. I prefer to forge damascus from high-carbon steels like 1095 and 15N20 because there is enough of a difference in carbon and chemical content between them to achieve a nice contrast in the damascus pattern.

Besides a nice contrast, the two steels are compatible, meaning they weld together well. Compatibility between the two steels you choose for damascus forging is extremely important. So far, I have always been able to achieve a strong weld using this steel combination, though I sometimes do employ other steels for damascus. Every smith has his or her own pet steels. This is the way it should be; what works well for me does not necessarily suit someone else.

To start making the damascus billet, the steel layers must be cleaned, either by sand blasting or grinding. Once the steel is clean, I cut it to size to size. I will forge out two billets, each measuring 1 1/4 inches high by 1 1/4 inches wide by 8 inches long. I start stacking my billet, first with a layer of 1095 steel, then with a layer of 15N20. I repeat this sequence until I get the number of layers I need to get started. In this case, 11 layers of steel is more than enough material to forge the pipe tomahawk.

Each billet is tied with a wire to help hold the steel together until I make my first weld. Some blade smiths use an electric welder to weld the ends of the billet and hold the steel together. I feel more comfortable tying the billet with wire, but this is just my personal preference.

The author uses a gas forge to heat his steel billet before hammering it during the forging process. He believes gas forges are cleaner, and that they offer more control and less smoke than coal forges.

Twisting is one way of manipulating steel to create a certain type of design or damascus pattern.

The authors damascus billet for the head of the tomahawk is more than 400 layers thick.

FORGING THE BILLET

A good fire is necessary after preparing a steel billet. I use a three-burner gas forge. The gas forge is a wonderful invention, extremely clean, produces a lot less smoke than a coal forge and offers a lot more control of the temperature. Both types of forges have their pluses and minuses, and both have their place in blade smithing.