Springer Series in Advanced Manufacturing

Series Editor

Duc Truong Pham

University of Birmingham, Birmingham, UK

The TheSpringer Series in Advanced Manufacturing includes advanced textbooks, research monographs, edited works and conference proceedings covering all major subjects in the field of advanced manufacturing. includes advanced textbooks, research monographs, edited works and conference proceedings covering all major subjects in the field of advanced manufacturing.

The following is a non-exclusive list of subjects relevant to the series:

Manufacturing processes and operations (material processing; assembly; test and inspection; packaging and shipping).

Manufacturing product and process design (product design; product data management; product development; manufacturing system planning).

Enterprise management (product life cycle management; production planning and control; quality management).

The following is a non-exclusive list of subjects relevant to the series:

1. Manufacturing processes and operations (material processing; assembly; test and inspection; packaging and shipping).

2. Manufacturing product and process design (product design; product data management; product development; manufacturing system planning).

Springer and Professor Pham welcome book ideas from authors. Potential authors who wish to submit a book proposal should contact Anthony Doyle, Executive Editor, Springer, e-mail: anthony.doyle@springer.com.3. Enterprise management (product life cycle management; production planning and control; quality management).

More information about this series at http://www.springer.com/series/7113 Emphasis will be placed on novel material of topical interest (for example, books on nanomanufacturing) as well as new treatments of more traditional areas.

As advanced manufacturing usually involves extensive use of information and communication technology (ICT), books dealing with advanced ICT tools for advanced manufacturing are also of interest to the Series.

Springer and Professor Pham welcome book ideas from authors. Potential authors who wish to submit a book proposal should contact Anthony Doyle, Executive Editor, Springer, e-mail: anthony.doyle@springer.com.

Sotiris Makris

Cooperating Robots for Flexible Manufacturing

1st ed. 2021

Sotiris Makris

Laboratory for Manufacturing Systems and Automation, Department for Mechanical Engineering and Aeronautics, University of Patras, Patras, Greece

ISSN 1860-5168 e-ISSN 2196-1735

Springer Series in Advanced Manufacturing

ISBN 978-3-030-51590-4 e-ISBN 978-3-030-51591-1

https://doi.org/10.1007/978-3-030-51591-1

Springer Nature Switzerland AG 2021

This work is subject to copyright. All rights are reserved by the Publisher, whether the whole or part of the material is concerned, specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed.

The use of general descriptive names, registered names, trademarks, service marks, etc. in this publication does not imply, even in the absence of a specific statement, that such names are exempt from the relevant protective laws and regulations and therefore free for general use.

The publisher, the authors and the editors are safe to assume that the advice and information in this book are believed to be true and accurate at the date of publication. Neither the publisher nor the authors or the editors give a warranty, expressed or implied, with respect to the material contained herein or for any errors or omissions that may have been made. The publisher remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This Springer imprint is published by the registered company Springer Nature Switzerland AG

The registered company address is: Gewerbestrasse 11, 6330 Cham, Switzerland

To Sophia, John and Dimitra

Preface

This book is the derivation of my research work at the Laboratory for Manufacturing Systems and Automation, University of Patras in Greece. It is based on close interaction with both industry and research colleagues. There have been many great ideas conceived over these years of research on the topic of cooperating robots for flexible manufacturing. This book writing is an effort to share these experiences with a broader audience in a format that is concise enough to summarize many different concepts but also provides adequate detail and references to allow those interested to follow similar a direction.

This book aims to consolidate the content of discussions and experiences with experts, practitioners and engineers in manufacturing systems. With the great variety of manufacturing systems, we had the opportunity to study a noteworthy set of methods and tools have been produced. The aim of the book is sharing this experience with academia and industry practitioners hoping to contribute to improving manufacturing practice. While there is a plethora of books detailed enough to teach principles of robotics, this book offers a unique opportunity to dive into the practical aspects of implementing real-world complex robotic applications.

The term Cooperating robots in this book refers to robots that either cooperate between themselves or cooperate with people. The book investigates aspects of cooperation towards implementing flexible manufacturing systems. Therefore, manufacturing systems are the main driver behind the discussion on implementing such robotic systems.

Numerous methods have been proposed to design and to operate manufacturing systems. This book aims to introduce a novel set of methods for designing and operating manufacturing systems consisting of cooperating robots. Many methods are available in the literature on designing or operating robotized manufacturing systems when the main priority is efficiency and robustness; the essential element of these robotized manufacturing systems is the need for flexibility.

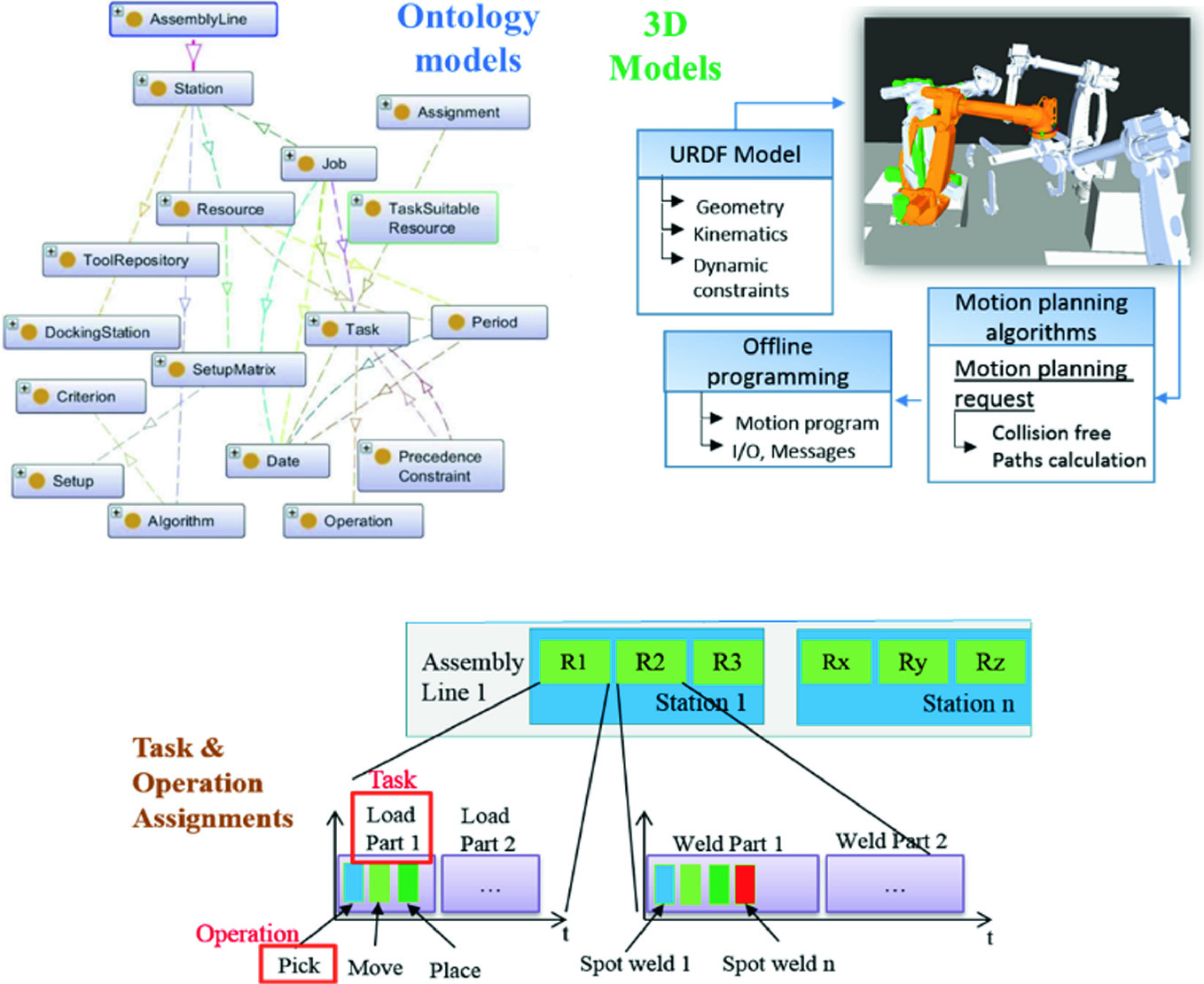

Initially, the concept of a manufacturing system will be briefly introduced, followed by aspects of flexibility. Following the key aspects of robotic systems will be introduced while the discussion will be streamlined towards implementing systems of cooperating robots towards flexible manufacturing systems. Aspects of designing such systems, such as considering material flow, logistics, processing times, shop floor footprint and design of flexible handling systems, are going to be discussed. Additionally, key issues in operating such systems involve decision making, autonomy, cooperation, communication, task scheduling, motion generation and distribution of control at the control level of different devices among others.

The book consolidates knowledge published in papers with co-authors; however, it introduces several novel concepts that have not been published before. It presents a number of chapters in the form of technical papers discussing industrial challenges and approaches taken. These chapters are organized in four major parts. Part I introduces the topics of cooperating robots in two dimensions. On the one hand, there are the topics of robots cooperating among themselves, and on the other hand, there are the aspects of robots cooperating with humans. Part II includes aspects of robot to robot cooperation. Part III elaborated aspects of collaborative robotics, namely humans cooperating with robots. Part IV summarizes with an outlook for the future.