CarTech

CarTech, Inc.

39966 Grand Avenue

North Branch, MN 55056

Phone: 651-277-1200 or 800-551-4754

Fax: 651-277-1203

www.cartechbooks.com

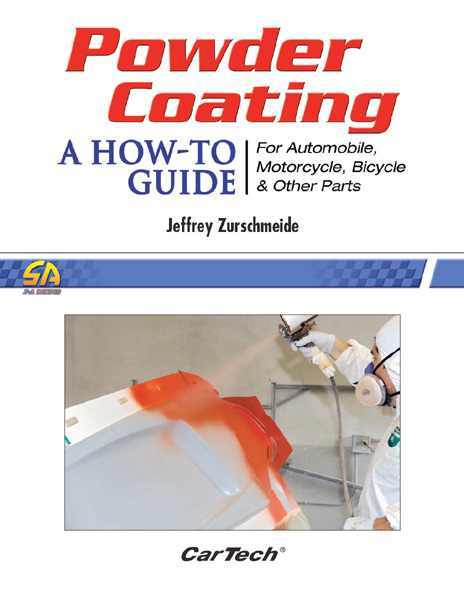

2015 by Jeffrey Zurschmeide

All rights reserved. No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without prior permission from the Publisher. All text, photographs, and artwork are the property of the Author unless otherwise noted or credited.

The information in this work is true and complete to the best of our knowledge. However, all information is presented without any guarantee on the part of the Author or Publisher, who also disclaim any liability incurred in connection with the use of the information and any implied warranties of merchantability or fitness for a particular purpose. Readers are responsible for taking suitable and appropriate safety measures when performing any of the operations or activities described in this work.

All trademarks, trade names, model names and numbers, and other product designations referred to herein are the property of their respective owners and are used solely for identification purposes. This work is a publication of CarTech, Inc., and has not been licensed, approved, sponsored, or endorsed by any other person or entity. The Publisher is not associated with any product, service, or vendor mentioned in this book, and does not endorse the products or services of any vendor mentioned in this book.

Edit by Paul Johnson

Layout by Monica Seiberlich

ISBN 978-1-61325-240-6

Item No. SA349

Library of Congress Cataloging-in-Publication Data Available

Written, edited, and designed in the U.S.A.

10 9 8 7 6 5 4 3 2 1

Title Page:

Fiberglass and composite surfaces are usually sprayed with liquid gel-coat. This gives the parts some of the properties of powder coat, but gel-coat is not nearly as tough as powder coat.

Back cover:

Top:

When using the dual-voltage gun from Eastwood, you use the identical technique as with the original HotCoat gun. The only difference is in the electrical charge used to stick the powder to the part. You can leave this system on high voltage unless youre working on a part with a complex shape.

Middle Left:

Some parts are more difficult to spray than others. To get powder into the valleys between the cooling ribs, we turned the gun sideways and boosted the air pressure a little. The powder was propelled into the low areas. This will be a nice dress-up item under the rear end of a racing BMW.

Middle Right:

Powder has been applied to the spring, and it has cured in the oven. The results are spectacular. The lesson is simple and easy: Dont skimp on your cleaning and prep!

Bottom:

When spraying a metal part with powder coat, you need to insert plugs and mask off all areas that will not receive powder finish. These silicone plugs come in a variety of sizes, and they are well suited to keeping powder out of threaded fittings and any places you dont want powder to get.

OVERSEAS DISTRIBUTION BY:

PGUK

63 Hatton Garden

London EC1N 8LE, England

Phone: 020 7061 1980 Fax: 020 7242 3725

www.pguk.co.uk

Renniks Publications Ltd.

3/37-39 Green Street

Banksmeadow, NSW 2109, Australia

Phone: 2 9695 7055 Fax: 2 9695 7355

www.renniks.com

CONTENTS

A great number of people have helped bring this book to fruition. First is my great friend and colleague Dan Burrill, whose support and enthusiasm cannot be replaced or understated. Mark Scholz also put in some substantial time and effort helping out with the work on coating projects for the book. Thanks also to my editor, Paul Johnson, who keeps me honest and on task.

I must acknowledge the great support received from The Eastwood Company. Eastwood built its business supporting automotive hobbyists starting with its powder coating products, and it remains the gold standard for the home restorer and fabricator. Throughout this book you find frequent reference to Eastwood products, and for full disclosure, those products were provided by Eastwood at no cost to me. Although it may be tempting for some to see a cynical relationship in this, the fact is that I dont have to embellish the truth: Eastwood products are clearly the best available, and if you try all the products I have tried in the research phase of this book, I believe you will agree with that assessment.

Jeffrey Zurschmeide is an inveterate tinkerer, and loves to learn new skills and putter around in his workshop. Whether its traditional coal-fired blacksmithing or learning to lay up dry carbon fiber, he is ready to give it a try and then write about the process.

Jeffrey lives in Oregon, where he earns his living as a freelance automotive journalist, writing for a variety of magazines such as SportsCar, Sports Car Market, Loud Pedal, Amici di Maranello, and others. He also writes about new cars for The Oregonian newspaper.

Jeffreys prior books include the Subaru High Performance Builders Guide; Automotive Welding: A Practical Guide (with Russell Nyberg); New MINI Performance Handbook; How To Design, Build & Equip Your Automotive Workshop on a Budget; and How to Fabricate Automotive Fiberglass & Carbon Fiber Parts (with Dan Burrill), all in CarTech Books SA Design series.

When I began this book, I had never powder coated a single item. The closest Id been to the process was a visit to a commercial powder coating business to do an interview for an article I had been assigned. Thats unusual because most books of this nature are written by experts, people with years or even decades of experience with the process. So why should this book be helpful to you? Simply put, because you are right where I was when I started, and powder coating is not difficult to do with a little help and advice.

Next page