Copyright 2010 by Stackpole Books

Published by

STACKPOLE BOOKS

5067 Ritter Road

Mechanicsburg, PA 17055

www.stackpolebooks.com

All rights reserved, including the right to reproduce this book or portions thereof in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without permission in writing from the publisher. All inquiries should be addressed to Stackpole Books, 5067 Ritter Road, Mechanicsburg, PA 17055.

Printed in China

10 9 8 7 6 5 4 3 2 1

First edition

Cover design by Tessa Sweigert

Library of Congress Cataloging-in-Publication Data

Wycheck, Alan.

Concrete crafts : making modern accessories for the home and garden / Alan

Wycheck. 1st ed.

p. cm.

ISBN-13: 978-0-8117-3579-7

ISBN-10: 0-8117-3579-6

1. Handicraft. 2. House furnishings. 3. Garden

ornaments and furnitureDesign and construction. 4. Concrete. I. Title.

TT910.W93 2010

745.5dc22

2009022982

eBook ISBN 978-0-8117-4031-9

Introduction

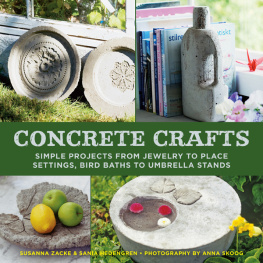

T his book will teach you how to make beauti ful pavers, tiles, tables, bowls, and plantersall out of durable concrete. Unlike many craft books on the market, it is designed for anyone who likes to be creative and doesnt want to spend a lot of money on a new hobby. After reading the step-by-step instructions and completing the projects, you will have the necessary skills to make a variety of concrete crafts, including a concrete bowl that floats on water. All of the projects start with a simple design that you can build upon using your own creativity. It is best to read through each step of a project from start to finish before beginning that project. By doing so, you will have a good understanding of what will be required in the steps ahead, and each project will be a success.

Concrete touches our lives almost every day.We usually think of sidewalks and highwayswhen we think of concrete; however, concretecan be beautiful as well as functional. It is themost-used man-made substance on our planet,with approximately 7 billion cubic yards usedevery year. To give you an idea of how much 7billion cubic yards is, the Hoover Dam required4.5 million cubic yards of concrete, which isenough to make a 4-foot-wide sidewalk aroundthe entire world at the equator. And that's justone concrete project. Most concrete is used forarchitecture and civil engineering projects; estimatesshow that China uses about half of all theconcrete in the world. The potential designsmade with concrete are limited only by one'simagination. Although concrete is typically heavy, even the issue of weight can be overcomewhen designing concrete products. This book isintended to introduce you to the world of concretewith practical, inexpensive projects that youcan use for both function and art. These projectsrequire basic tools that many of you probablyalready have, and if you don't have them, theyare readily available. All of the projects can bemade quickly and inexpensively. At the timeof printing, a 94-pound bag of gray Portlandcement costs about $10, and a premixed 80-pound bag costs about $5. I hope to instill inyou the desire to further explore concrete craftingand come up with designs of your own.

Typical use of concrete.

Getting Started

Safety

Common sense is the rule when working with concrete. Use a dust mask and protective glasses when mixing concrete. Wet concrete is caustic and can cause skin irritation and burns. I tend to work with my bare hands, but if you are going to be in contact with wet concrete for long periods of time, you should denitely wear gloves. If you get concrete in your eyes, flush it out with clean water immediately. If you get it on your skin and it irritates you, wash it off with water. Cured concrete is nontoxic and as harmless as stone.

Making Concrete

C oncrete is an amazing and versatile materialthat has been used for thousands of years. Itcan be made into almost any shape and size. TheEgyptians used a primitive form of concrete tobond stone and brick. The Romans used it tomake roadways and buildings. In our modernworld, one would have a hard time making itthrough a day without walking on, driving over,or living with concrete. Concrete is made ofthree basic components: Portland cement, water,and aggregates (sand, gravel, rock, and so on). Instandard concrete mixes, the amount of water plays an important role in the hardness of thecured concrete. If too much water is added to aparticular mix of concrete, it will be weaker thanif the proper amount of water were added. Thelightweight mixes we use in this book are not ashard or strong as the standard mixes, but theywill work just fine in some projects.

The easiest way to make concrete is to purchase dry, premixed bags, which are available in home improvement stores, hardware stores, and concrete supply stores. Premixed bags range from 10 to 90 pounds, come in various name brands, and are offered in several strengths. The strength is measured in pounds per square inch (psi); premixed bags range from about 2,500 psi to 6,000 psi. As mentioned earlier, the strength will be weakened if too much water is added to these dry mixes. I recommend high-strength concrete with fiber for the projects in this book. Concrete hardens to its full potential in about four weeks, at which time it can be measured for strength. The high-strength mixes I provide for you get very hard after twenty-eight days of curing.

Common aggregate

On the left is inch or smaller limestone. On the right is pea gravel, the stone aggregate typically used in premixed bags of concrete. Notice the rounded shape of the pea gravel.

Some examples of lightweight aggregates. From left to right are perlite, peat moss, and vermiculite.

The aggregate you choose plays a very important role in the concrete mix because it occupies the majority of the space. Aggregate is basically filler, but its different sizes, shapes, and composition affect the workability and strength of the concrete. You can typically add up to five parts aggregate; more than that will impede the concrete's workability. I recommend small limestone as an aggregate. Pea gravel, which is a rounded hard pebble, also works well, especially if it's exposed on the final project or used when making countertops with squared corners. The rounded form of the pea gravel allows the Portland cement and sand to thoroughly fill the corners of the mold. The sharp corners in the limestone aggregate can sometimes block the smaller aggregatethe sandfrom filling the corners completely. Pea gravel, however, is not as strong as limestone. Also, acrylic fiber and water reducer are commonly added for additional strength. A standard concrete mix will yield about 3,500 psi.