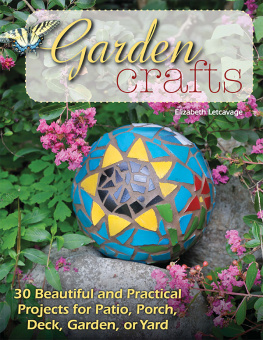

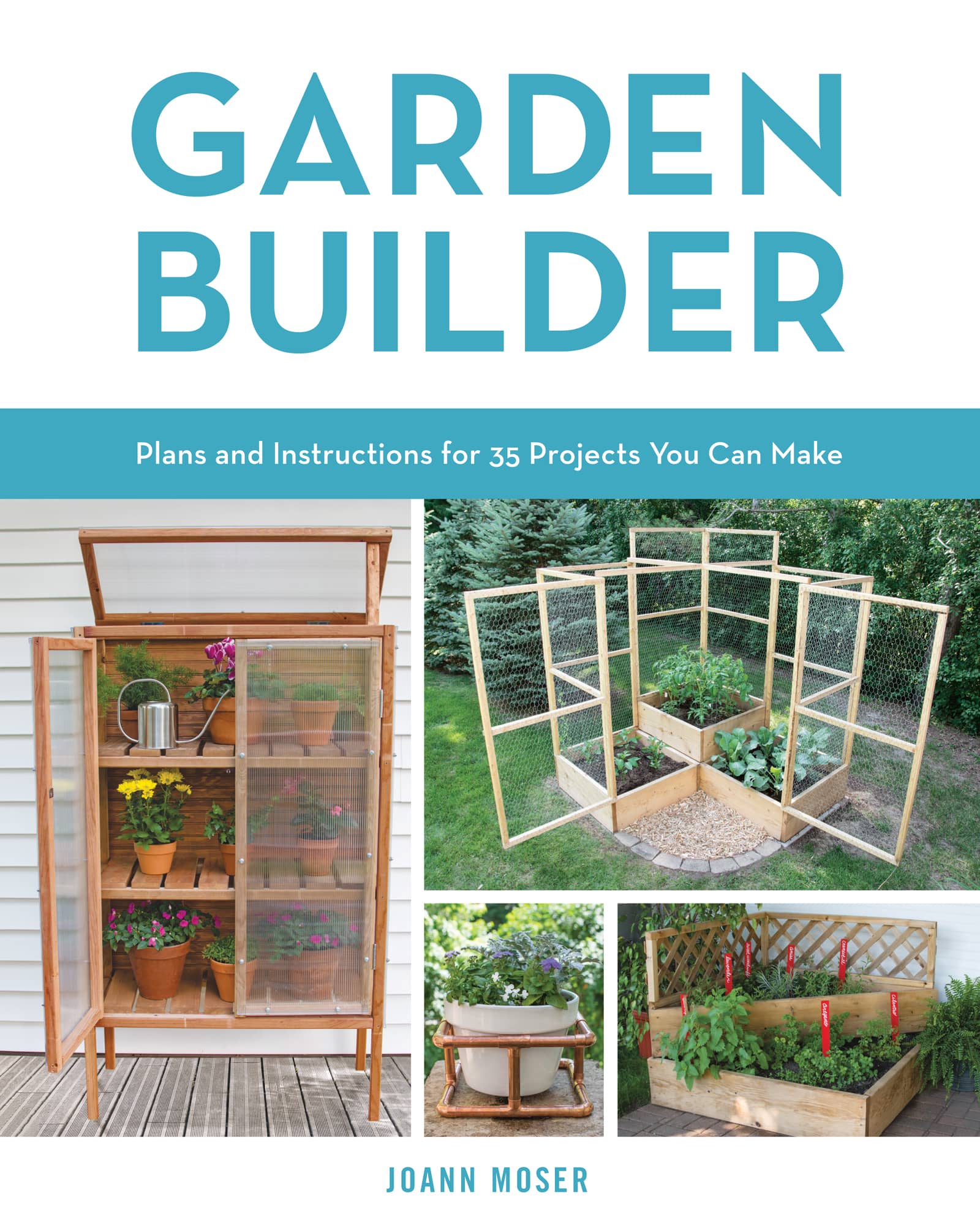

GARDEN BUILDER

Plans and Instructions for 35 Projects You Can Make

JOANN MOSER

Acknowledgments

SPECIAL THANKS TO Mark Johanson for the opportunity to work, once again, with him and his stellar team at Cool Springs Press, including (but not limited to) Brad Springer and Jordan Wiklund. From copy editing to book layout and design and everything in between, they are the magicians that turned my words and photographs into an honest-to-goodness book. Thanks, also, to Alisa Carbone for her help in spreading the word.

Another person whose contribution directly influenced the existence of Garden Builder is my DIY cohort Nick Moser. The strong hands in the forthcoming pages are his, as he constructed the vast majority of the projects youre about to see. We always design as a team, but his is the voice of reason when rules of mechanics are involved. In that way, he supplies the much-needed substance to my style. Although I lobbied to have Nicks name included on the cover of this book right next to mine, he demurred, perfectly content to be my silentbut fiercestchampion. Thank you, my love.

Introduction

HAVE YOU EVER WANTED TO ADD PERSONALITY TO YOUR GARDEN? Or needed a utilitarian item to make your gardening experience more enjoyable? Have you gone to a garden center or big box store but couldnt find exactly what you were looking foror maybe you could find it but you couldnt afford it?

I cant tell you how many times this has happened to me. Im lucky to live with a woodworker who owns just about every woodworking tool imaginable. If I cant find what I want at the store, or its too expensive, I can sketch up a design and place an order with my very own handy-person.

Not everyone is as lucky as I am. And thats where the projects in Garden Builder come into play. Chosen for their ease of construction, the woodworking projects utilize simple joinery and can be made with common hand tools such as a drills and circular saws. Designs were created with standard board widths and lengths in mind, which minimizes waste. As for the non-woodworking projects, they are similarly easy to construct and employ equally simple assembly techniques.

For the more seasoned woodworkers among you, note that each project is completely adaptable to more sophisticated joinery and joining methods. That means your table saw, compound miter saw, pneumatic nailer, pocket screw jig, and soldering torch can get a workout, too.

Another thing youll notice about some of the projects in Garden Builder is their adaptability. The raised miniature garden shown , which can be made with or without pest-proof panels. It consists of boxes made in two different sizes that can be configured and stacked to suit any yard, no matter the size.

The most unique and interesting gardens consist of a little of everything, and so too does Garden Builder. From decorative focal points to helpful additions and everything in between, these projects are meant to the enhance the garden as well as our gardening experience. We hope their construction, their presence when completed, and the satisfaction of building them yourself provide you with great joy.

NOMINAL SIZE | ACTUAL SIZE |

1 2 | /" 1/" |

1 3 | /" 2/" |

1 4 | /" 3/" |

1 6 | /" 5/" |

1 8 | /" 7/" |

2 4 | 1/" 3/" |

2 6 | 1/" 5/" |

2 8 | 1/" 7/" |

2 10 | 1/" 9/" |

Lumber Issues

If you build the projects in this book according to the listed dimensions and wood species, construction should be relatively easy. You might run into difficulty, though, if you choose to adapt the plans to change the sizes of the projects. The problem here will stem from the fact that nominal lumber sizes are different than the actual sizes. Moreover, the actual sizes may vary depending on the lumber grade and species you buy.

The word nominal means in name only. Although experienced woodworkers and carpenters are well aware of this fact, it can surprise beginning woodworkers to learn that a construction 2 4, for example, actually measures 1/ 3/ inches. The reason for this has to do with the milling of the lumber. Although a 2 4 may arrive for its final finishing as a true 2 4, once it is planed down for sale, its dimension changes to its actual 1/ 3/-inch dimensions.

This is true of pretty much any lumber you buy, no matter what the species. The difference between nominal and actual dimensions varies depending on the lumber grade and type, but it is always there. Fine-quality hardwoods have a very predictable variationa 1 4, for example, is always / 3/ inchesbut on rough-sawn cedar, the variation can be less precise. A 1 8 plank of rough cedar is assumed to be / 7/ inches, but in actuality might be / 7/ inches. And because many of the projects in this book are built with cedar, you have a good chance of running into measurement differences.

The moral here is that you will need to double check measurements for the parts when building the projects in this book. Weve sized the elements based on standard assumptions for actual board sizes versus nominal, but there is a good chance that the rougher grade lumbers may be different than the normal actual dimensions.

While were still discussing nominal board measurements, we need to consider board lengths as well. Dont assume a 6-foot board measures 6 feet long just because its in the 6-foot bin at the lumberyard. Often, board stock measuring less than 8 feet are drops, or leftover cuts from a longer board. So that 6-foot board may measure up to an inch short. Because many of the projects featured in this book were designed to minimize material waste, measure the board lengths to make sure youre getting the full measurement.

Squaring Up a Project

Now lets say youve run the numbers, and youve implemented the formulas provided. You arrange your stiles and rails for assembly. You even clamp them all together. But when youre finished gluing and screwing the structure, the result is anything but in square. Theres a quick trick to make sure all your angles are 90 degrees, and it goes like this: simply measure from one outside corner diagonally to its opposite corner, then repeat this same technique for the other two corners. If their measurements are the same, the structure is square. Be aware that the same technique can be used to square up a structure that is a lready assembled. In this case, bar clamps can be used to rack the structure into square.

Lumber Type

Although pressure-treated lumber may be used to construct many of the following projects, it is not advised to use pressure-treated lumber to construct planters and raised gardens that will be producing edibles. For those in which food will be grown, choose naturally rot-resistant wood species that are readily available to you. For us, that means rough-sawn western red cedar. If you dont already know what choices are available to you, rely on the expertise of the professionals at your local lumber yard for advice.