Building Homebrew Equipment

excerpted fromBrew Ware

Karl F. Lutzen & Mark Stevens

CONTENTS

Introduction

Take one step into a homebrew store, or flip through the pages of any magazine about homebrewing, and its easy to see that home-brewing can be an expensive hobby. From the counterflow wort chiller to a refrigerated keg system to a complete brewery, a serious homebrewer can spend thousands of dollars on a homebrewery.

Most of the products offered by the many homebrewing equipment manufacturers and suppliers have been produced with the needs and wants of the consumer in mind. Companies in the brewing industry are constantly coming up with products that they hope will make the brewing process easier, yet also allow the homebrewer to make a better beer. Many of the best-selling homebrewing supplies and accessories were created by homebrewers like yourself who developed a product that greatly aided them in their quest for professional-quality ales and lagers.

Despite the dizzying number of gadgets on the market, there is one thing to take solace in brewing is a simple science. No matter if you are a beginner using strictly kits or a professional at a 30,000- gallon-a-year microbrewery, beer is still made using the same five basic steps: making wort, boiling, cooling, fermenting, and packaging (carbonating). You can make award-winning beer using a simple starter kit. Yet there is equipment that doesnt come with the beginners kit that will help you produce a higher-quality beer. Wort chillers, mashing and lauter tuns, and kegging systems are not required equipment for beginners, but most experienced homebrewers cannot produce their product without them.

All of the equipment described here can be purchased at your local brewing supply store or at one of the growing number of national homebrewing supply distributors. But building this equipment yourself offers two attractions: 1) You will save money; and 2) you can make changes to the equipment as is necessary to work in conjunction with your work or storage space, or existing equipment.

The projects here are designed for anyone from beginning to advanced brewers, kit brewers to all-grain masters. Most presuppose brewing experience (i.e., you will have a rough idea about how to use homemade equipment), and all require a working knowledge of and access to common tools found in a workshop (drills, saws, hardware, etc.). We hope you enjoy making these products and, with their help, succeed in achieving the ultimate goal excellent beer.

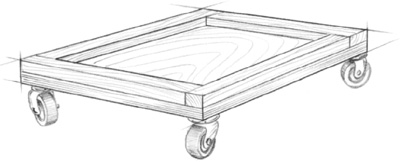

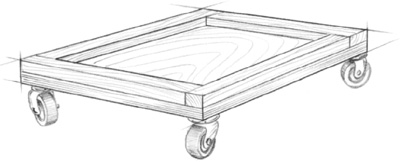

The Rolling Carboy Carrier

The best way to move carboys is with rolling carboy carriers. They can be made at a minimum cost (we were able to make the rolling carboy carrier with only scrap wood from our work shed), they can be assembled quickly, and they provide a much safer and easier way to handle glass carboys. You basically construct a platform with a lip to keep the carboy in place and then put caster wheels on the bottom so that it can be rolled from the brewery area to the fermenter area. This doesnt solve the problem of moving carboys up and down stairs, but if you brew and ferment on the same level, its a real back-saver.

The best way to move a carboy is with a rolling carboy carrier like this.

MATERIALS FOR A ROLLING CARBOY CARRIER

1 13 13 platform of plywood

4 1-wide 12-long strips of plywood

4 swivel coasters

16 #10 -long wood screws

Directions

1. Cut out the platform and strips from a plywood sheet.

2. Glue and clamp the strips to the platform in the pattern illustrated.

3. Attach the swivel casters with the wood screws 1 in from the edges (be sure to drill pilot holes first).

4. Set the carboy on the platform, fill, attach airlock, and roll into the fermenter closet or corner.

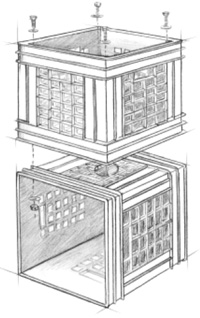

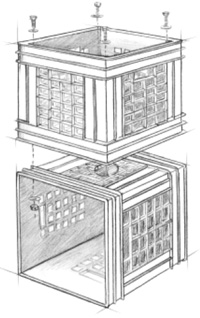

The Carboy Stand

Milk crates provide an easy way to build an inverted carboy stand for the BrewCap system. A carboy stand is a necessity if you want to effectively drain your carboys after sanitizing them, or if you are interested in using the BrewCap (made by BrewCo in Boone, North Carolina). The BrewCap was developed to allow brewers a more effective way to remove the expended yeast and trub that settle at the bottom of the carboy. With your carboy in an inverted position, the BrewCap holds two tubes in place: The short one extends into the neck and removes the expended yeast and trub, and the long one extends to the top of the inverted carboy and is a pressure-relief mechanism. Using a BrewCap, you will no longer need to siphon the wort into a secondary fermenter, and it is a completely closed system.

MATERIALS FOR A CARBOY STAND

2 (identical) milk crates

4 bolts, washers, and nuts (size will depend on the size and design of your milk crates)

Directions

1. Saw a hole in the bottom of one of the milk crates (the top crate) large enough that the neck of the inverted carboy extends through the hole.

2. Set the second crate (the bottom crate) on its side and face the open side toward you; cut a large square hole in the top of the crate to accommodate the neck of the carboy and the hoses.

3. Fasten the two crates together using bolts, washers, and nuts.

Milk crates provide an easy way to build an inverted carboy stand for the BrewCap system.

Immersion Wort Chillers

One of the longest steps of the extract brewers brewing process (other than the wort boil) can be the cooling of the wort. Especially if you still are using the ice bath and diffusion method of cooling your wort, you know how long it takes to get the 200 wort down to a temperature appropriate for pitching the yeast. The immersion chiller can reduce your cooling time to 15 minutes.

Immersion chillers are usually built from a coil of copper tubing with connectors on each end to which hoses are attached (garden hoses are often used). One connector is run to a source of cold water; the other is run to a drain for expelling the hot water. The immersion chiller offers a simple, effective way to quickly cool hot wort. Cooling wort quickly is important for two reasons. One: You can achieve a more effective cold break, which is the point when suspended proteins drop out of suspension as the wort is cooled. And two: You reduce the amount of time the wort is exposed to possible airborne pathogens.

Basic Immersion Chiller

Chillers are readily available from many homebrewing supply stores for $30 to $35; however, they can also be built at home for a bit less than that. One advantage to building the chiller yourself is that you can adapt the plans to suit your own needs. Well describe a few ways that chillers can be adapted to work more effectively.

When you build a wort chiller, the most critical aspect is the tubing you choose. Copper works well because it efficiently transmits heat energy and is readily available at fairly low cost. Stainless-steel tubing would work, but it costs more. Aluminum also works fine, but some brewers feel that it tends to give the beer a metallic taste. There is, however, no real evidence of such flavor problems. Your tubing should be in diameter. If you use a thinner tube, you will achieve potentially greater efficiency because the thinner tube will give you more surface area per volume. However, chillers made from -diameter tubing tend to take much longer to cool wort and are prone to clogging. Using a -diameter tubing gives you good efficiency and acceptable cooling times, and it avoids clogging.