APICS - CSCP 2020 Module 2 Section C

Here you can read online APICS - CSCP 2020 Module 2 Section C full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. genre: Home and family. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:CSCP 2020 Module 2 Section C

- Author:

- Genre:

- Rating:5 / 5

- Favourites:Add to favourites

- Your mark:

- 100

- 1

- 2

- 3

- 4

- 5

CSCP 2020 Module 2 Section C: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "CSCP 2020 Module 2 Section C" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

CSCP 2020 Module 2 Section C — read online for free the complete book (whole text) full work

Below is the text of the book, divided by pages. System saving the place of the last page read, allows you to conveniently read the book "CSCP 2020 Module 2 Section C" online for free, without having to search again every time where you left off. Put a bookmark, and you can go to the page where you finished reading at any time.

Font size:

Interval:

Bookmark:

This section focuses on integrating returns, recalls, repairs, remanufacturing, and other end-of-life topics into the supply chain so that these can not only be dealt with efficiently but also become a source of revenue. National and local governments are increasing regulations in this area, so getting reverse logistics right will help compliance be just a regular part of doing business and keep waste and hazardous materials out of landfills.

Reverse logistics is often a required cost of doing business. It can be a severe drain on organizational profitability and could eventually contribute to an organizations demise if it is continually just an expensive afterthought. However, if it is handled strategically and the organization invests time and energy in planning the returns, repairs, reuses, recycling, and responsible disposals they are obligated to handleincluding the disposal of hazardous wastethey can, in some cases, generate revenue from these sources to offset the costs, and the costs themselves can be kept reasonable by focusing on smart policy and efficient practices.

The key processes that supply chain managers need to be able to perform related to managing reverse logistics are

Identifying requirements of reverse logistics

Designing a reverse strategy and process

Implementing a reverse strategy and process.

The following is a general overview of these processes. The information required to plan and execute these processes is presented in this sections chapters.

The process of identifying the requirements of reverse logistics involves the following steps:

Assessing the as-is state of reverse logistics strategy and processes

Determining the stakeholders for each product or product groups reverse logistics requirements (e.g., customers; finance and other executives; health, safety, and environmental regulators; interest groups; transporters and 3PLs, etc.)

Gathering requirements from each stakeholder group

Consolidating and categorizing requirements

Determining the impact of stakeholder requirements on strategic priorities (e.g., customer service impact)

Reviewing organizational and supply chain strategy to determine if stakeholders reverse supply chain requirements necessitate modifications to these strategies (i.e., these requirements are often overlooked during strategic planning)

The process of designing a reverse strategy and process involves the following steps:

Prioritizing requirements based on organizational and supply chain strategy

Designing the to-be state of reverse logistics, either during product development and introduction of new products or as modifications to existing operations

Analyzing the gaps between the as-is and to-be states

Developing a quantitative and qualitative benefit-cost analysis to justify strategic choices and tradeoffs

Generating a reverse logistics strategy, including how the strategy might need to change at various points in the product life cycle

Influencing executive support to champion and lead the strategy and allocate funding

Designing information systems and network locations for reverse supply chain activities

Designing processes and policies for each product, subcomponent, waste item, and raw material entering the reverse logistics hierarchy (i.e., whether to reduce, reuse, recycle, recover energy during disposal, or dispose in a responsible landfill)

The process of implementing a reverse strategy and process involves the following steps:

Gaining final executive approval and funding for specific infrastructure and process changes or contract negotiations to implement the strategy

Planning and implementing projects to change processes and infrastructure

Contracting with third-party participants

Using change management to alter the culture of the organization to support the changes over the long term

Setting up metrics and goals for monitoring and controlling operations and customer service impact

Monitoring and controlling the processes and operations

Gathering feedback and implementing continuous improvement

Note that project management, continuous improvement, and change management are addressed in detail elsewhere.

This chapter is designed to

Identify activities supported by reverse logistics

Enumerate the business advantages and common requirements motivating development of a reverse logistics supply chain

Describe the strategic impact on reverse logistics and design considerations related to network locations, warranty policies, return authorization policies, logistical network make-or-buy decisions, and product life cycle

Describe the benefits of a well-organized reverse supply chain.

In this chapter well look at the phenomenon of reverse logistics and explore some of the strategic approaches that, in some cases, are not only mitigating the negative impact of product returns but are finding ways to make a profit on the back side of the supply chain.

What happens when you throw the supply chain into reverse? You have reverse logistics, defined in the APICS Dictionary, 16th edition, as

a complete supply chain dedicated to the reverse flow of products and materials for the purpose of returns, repair, remanufacture, and/or recycling.

The Dictionary defines the reverse supply chain as

the planning and controlling of the processes of moving goods from the point of consumption back to the point of origin for repair, reclamation, recycling, or disposal.

The reverse supply chain is also simply referred to as product returns.

Whatever one calls it, the reverse supply chain is a complete chain, a mirror image of the forward chain that carried the product to the customer in the first place. As such, it gives rise to mirror images of operations in the forward chaincustomer service (marketing in reverse), warehousing and transportation going in the opposite direction, unpackaging, disassembly, and remanufacturing or recycling (a return to raw materials). The products in the reverse chain wont necessarily move through the same nodes as products in the forward chain because fewer, and different, warehouses, may be required.

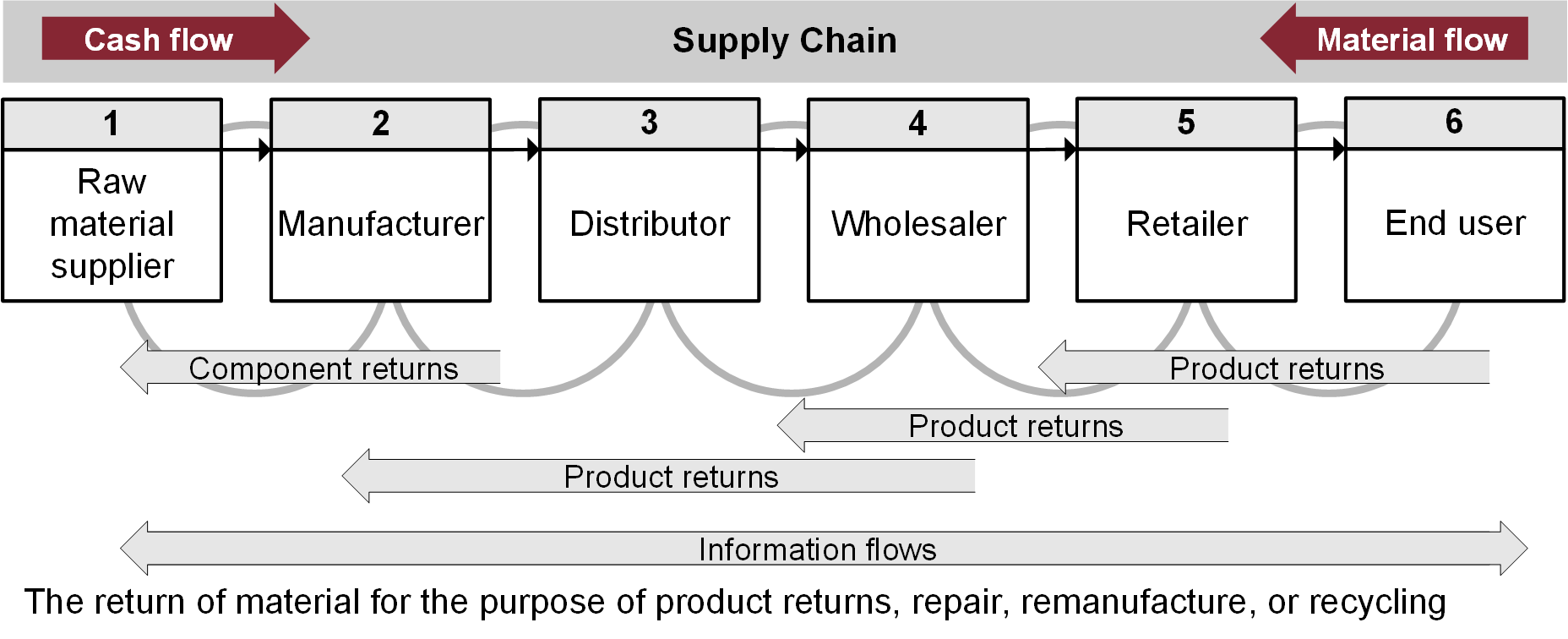

Exhibit 2-128 shows the direction of material and cash flows in the reverse supply chain and lists some reverse logistics activities.

Exhibit 2-128: Reverse Logistics

Reverse logistics can occur not only as customers are returning products that were purchased but also as retailers or distributors return products that failed to sell (e.g., if there are contractual agreements to take back unsold inventory for some amount of refund or rebate on future purchases) or were defective. Similarly, manufacturers might return defective or excess products to suppliers.

Font size:

Interval:

Bookmark:

Similar books «CSCP 2020 Module 2 Section C»

Look at similar books to CSCP 2020 Module 2 Section C. We have selected literature similar in name and meaning in the hope of providing readers with more options to find new, interesting, not yet read works.

Discussion, reviews of the book CSCP 2020 Module 2 Section C and just readers' own opinions. Leave your comments, write what you think about the work, its meaning or the main characters. Specify what exactly you liked and what you didn't like, and why you think so.