CarTech

CarTech, Inc.

838 Lake Street South

Forest Lake, MN 55025

Phone: 651-277-1200 or 800-551-4754

Fax: 651-277-1203

www.cartechbooks.com

2016 by Jim Smart

All rights reserved. No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without prior permission from the Publisher. All text, photographs, and artwork are the property of the Author unless otherwise noted or credited.

The information in this work is true and complete to the best of our knowledge. However, all information is presented without any guarantee on the part of the Author or Publisher, who also disclaim any liability incurred in connection with the use of the information and any implied warranties of merchantability or fitness for a particular purpose. Readers are responsible for taking suitable and appropriate safety measures when performing any of the operations or activities described in this work.

All trademarks, trade names, model names and numbers, and other product designations referred to herein are the property of their respective owners and are used solely for identification purposes. This work is a publication of CarTech, Inc., and has not been licensed, approved, sponsored, or endorsed by any other person or entity. The Publisher is not associated with any product, service, or vendor mentioned in this book, and does not endorse the products or services of any vendor mentioned in this book.

Edit by Bob Wilson

Layout by Monica Seiberlich

ISBN 978-1-61325-355-7

Item No. SA380

Library of Congress Cataloging-in-Publication Data Available

Written, edited, and designed in the U.S.A.

10 9 8 7 6 5 4 3 2 1

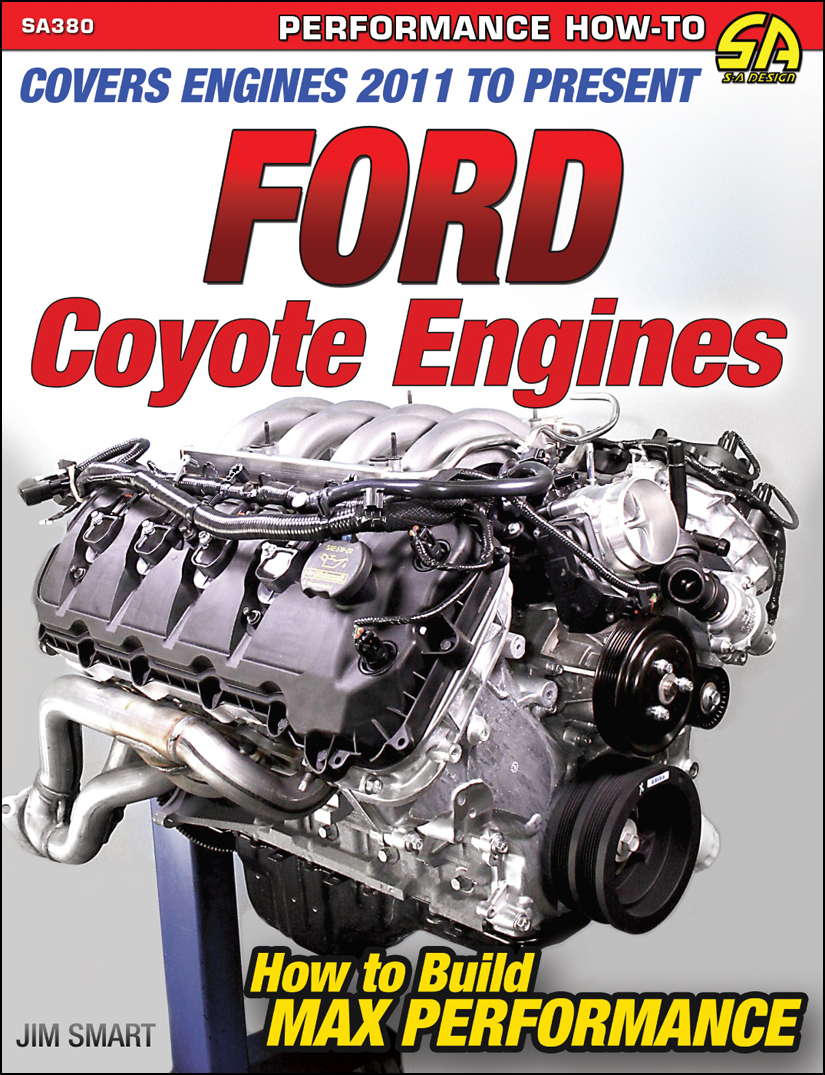

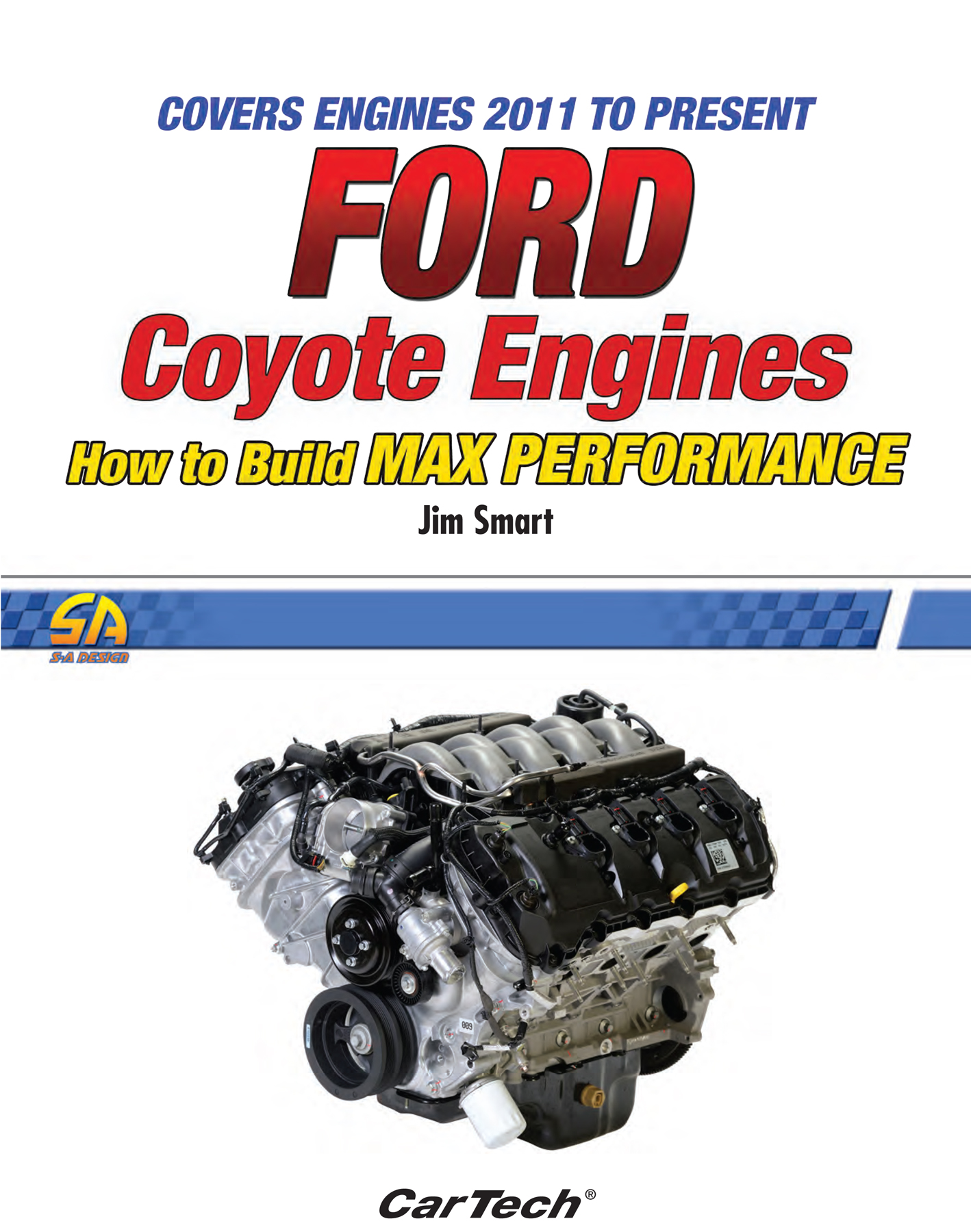

Title Page:

The box stock Ford Performance 5.0L Ti-VCT Coyote crate engine and related electronics is the best crate engine value going because this is a turnkey product with a warranty. On the dyno, void of accessories and an emissions system (catalytic converters), this crate Coyote makes more than 487 hp and more than 400 ft-lbs of torque. (Photo Courtesy Ford Performance Parts)

Back Cover Photos

Top:

The Coyotes camshafts ride directly on cylinder head journals. There are no cam bearings, just the oil wedge that the Coyotes lubrication system provides. This design nuance is carried over from the 4.6L and 5.4L Modular engines. Here, Performance Assembly Solutions, which builds Ford Performances crate Coyotes, applies engine-assembly lube to cam journals during assembly.

Middle Left:

Some confusion surrounds these piston-cooling oil jets, which provide good heat transfer to the oil and carry excessive heat away, especially in boosted applications. Coyote blocks from 2011 to 2013 had them, but then Ford dropped them. In the course of 20152016 production, piston-cooling jets returned. Expect to see some blocks with this provision and some without.

Middle Right:

Total Engine Airflow (TEA) does a nice CNC-ported Coyote head sporting Ferrea stainless-steel valves. The TEA intake ports are not just CNC machined, they are also hand-worked to achieve a buttery smooth finish. There are no lines and ridges to cause turbulence.

Bottom:

Crankshaft endplay is checked and documented. If it doesnt measure up to standards, the block and crank are disassembled and each is checked to find the cause. Thrust bearing thickness at the number-5 main bearing cap is how you modify endplay.

DISTRIBUTION BY:

Europe

PGUK

63 Hatton Garden

London EC1N 8LE, England

Phone: 020 7061 1980 Fax: 020 7242 3725

www.pguk.co.uk

Australia

Renniks Publications Ltd.

3/37-39 Green Street

Banksmeadow, NSW 2109, Australia

Phone: 2 9695 7055 Fax: 2 9695 7355

www.renniks.com

Table of Contents

Guide

CONTENTS

A book of this depth happens only with help from a lot of valuable people in the industry and close friends who have been making it happen for me for a lifetime. Mike Delahanty of Ford Performance Racing Parts has provided a complete base 5.0L Ti-VCT DOHC Coyote V-8 and most of the parts necessary to conduct dyno testing and prove this engine out repeatedly. Ford Performance Parts has offered this opportunity to take the high-tech Coyote and prove it out first-hand in an independent dynamometer room.

Mike also invited me to Detroit for a close look at how Ford Performance Aluminator crate engines are planned out and built by Performance Assembly Solutions (PAS) in Livonia, Michigan. Crate engines have long gotten a well-deserved bad rap over quality issues. However, the Aluminator Coyote crate engine is a huge exception to this belief because standards are very high and OEM in scope. These are world-class engines mass produced in an intimate environment where every engine, every step, experiences strict accountability. The staff talks with each other, and problems are discussed and rectified immediately.

Dennis Corn of Roush Performance invited me into its vast Livonia, Michigan, facility for an intimate look at how Roush has grown from a modest race shop to a huge research and development, and manufacturing operation from aftermarket parts and engines to valuable OEM engineering support. Founder and President Jack Roush came from humble beginnings to create what is easily one of the most respected race-oriented operations in the world. Roush Performance offers the enthusiast Ti-VCT Coyote crate engine performance in a variety of upscale Coyote Aluminator packages from Ford Performance.

Jim Grubbs of JGM Performance Engineering in Valencia, California, decided to take this project on and became very committed to its success. He and associate Jeff Latimer spent weeks preparing JGMs Super-Flow 901 dyno for testing. Vince Vicedo and Ryan Peart of JGM Performance Engineering took on the lions share of engine modifications and upgrades during dyno testing. The thrill on Jims face as we tested this high-tech V-8 has been nothing short of remarkable. Ray Herron at Ford Performance Racing Parts tech support department has been very supportive to our efforts in California. We call. He advises.

Ray McClelland of Full Throttle Kustomz in Fillmore, California, has been kind enough to come to JGM Performance Engineering to custom tune this Coyote test mule as weve made modifications. With Rays knowledge and extraordinary tuning abilities, we managed to gain more than 100 hp with simple bolt-on modifications in a naturally aspirated package.

Tim Gilpin at BBK Performance has been supportive to this effort, providing performance parts and tech support. Trent Goodwin at Comp Cams has supported my efforts more times than I can count through the years, providing cam kits, valvetrain components, and performance parts along the way. Moreover, Trent has provided incredible tech support.