CROWOOD METALWORKING GUIDES

HEAT

TREATMENT

CROWOOD METALWORKING GUIDES

HEAT

TREATMENT

RICHARD LOFTING

THE CROWOOD PRESS

First published in 2018 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2018

The Crowood Press 2018

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of thistext may be a direct infringement of the authors and publishers rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 442 1

Disclaimer

Safety is of the utmost importance in every aspect of metalworking. The practical workshop procedures and the tools and equipment used in metalworking are potentially dangerous. Tools should used in strict accordance with the manufacturers recommended procedures and current health and safety regulations. The author and publisher cannot accept responsibility for any accident or injury caused by following the advice given in this book.

Contents

Introduction

The term heat treatment can conjure up all sorts of connotations, but in this book we are dealing with the heat treatment and its consequences to metal that we use in the home or hobby workshop. Ostensibly one piece of steel looks very much like another, but steel is an alloy of two or more elements and depending on what these elements are, and in what proportions they are added, will make all sorts of differences to the properties of that particular alloy. As most people know, steel is widely used in buildings and the worlds infrastructure, such as bridges, electricity pylons, etc. If the wrong grade of alloy was used there would be all sorts of disasters, such as bridges bending like rubber or pylons snapping off in high winds I digress.

Heat treatment requires elevated temperatures and soaking periods, the ideal equipment is a gas-powered oven/kiln.

Obviously we are talking about materials in the home workshop, so not on so large a scale. In the world of industry there have evolved many techniques and alloys that, although very interesting, are beyond the realms of our world. For example, some hardenable steels require soaking for many hours at high temperature to fully change the crystal structure within, and then special tempering sequences including cryogenic treatments to attain the full hardness and toughness required.

In this book we will be looking at materials and techniques that can be used in our home workshops to produce useful tools, etc. by the use of simple heating sources, i.e. a propane blowtorch and the use of water, brine and oil as quenching mediums.

For those who are interested, goes some way to describe the technical details as to how the steel composition affects the hardening characteristics. In simple terms, to harden steel it needs to heated to a temperature where the crystal structure changes. If allowed to cool slowly it will revert to its original soft condition, but if cooled fast enough, i.e. quenched, then the altered structure will remain, in effect freezing the crystal structure and leaving the steel as hard as glass. The only problem is that with hardness comes brittleness. The process of tempering loses some of the hardness obtained during hardening in exchange for toughness, making the tool or whatever we have made useable without breaking.

A washer being reheated after being placed in case hardening compound, before quenching in cold water.

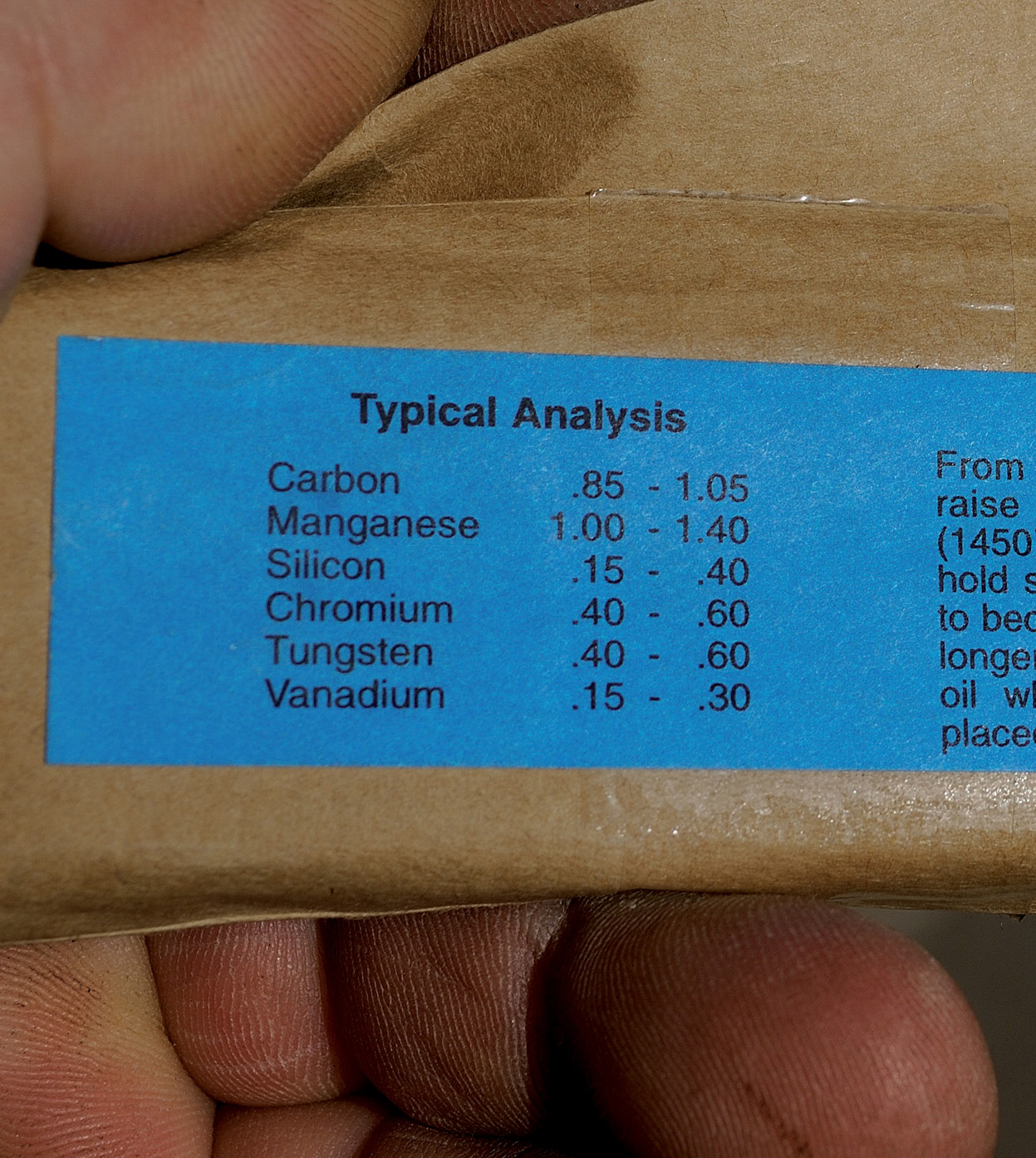

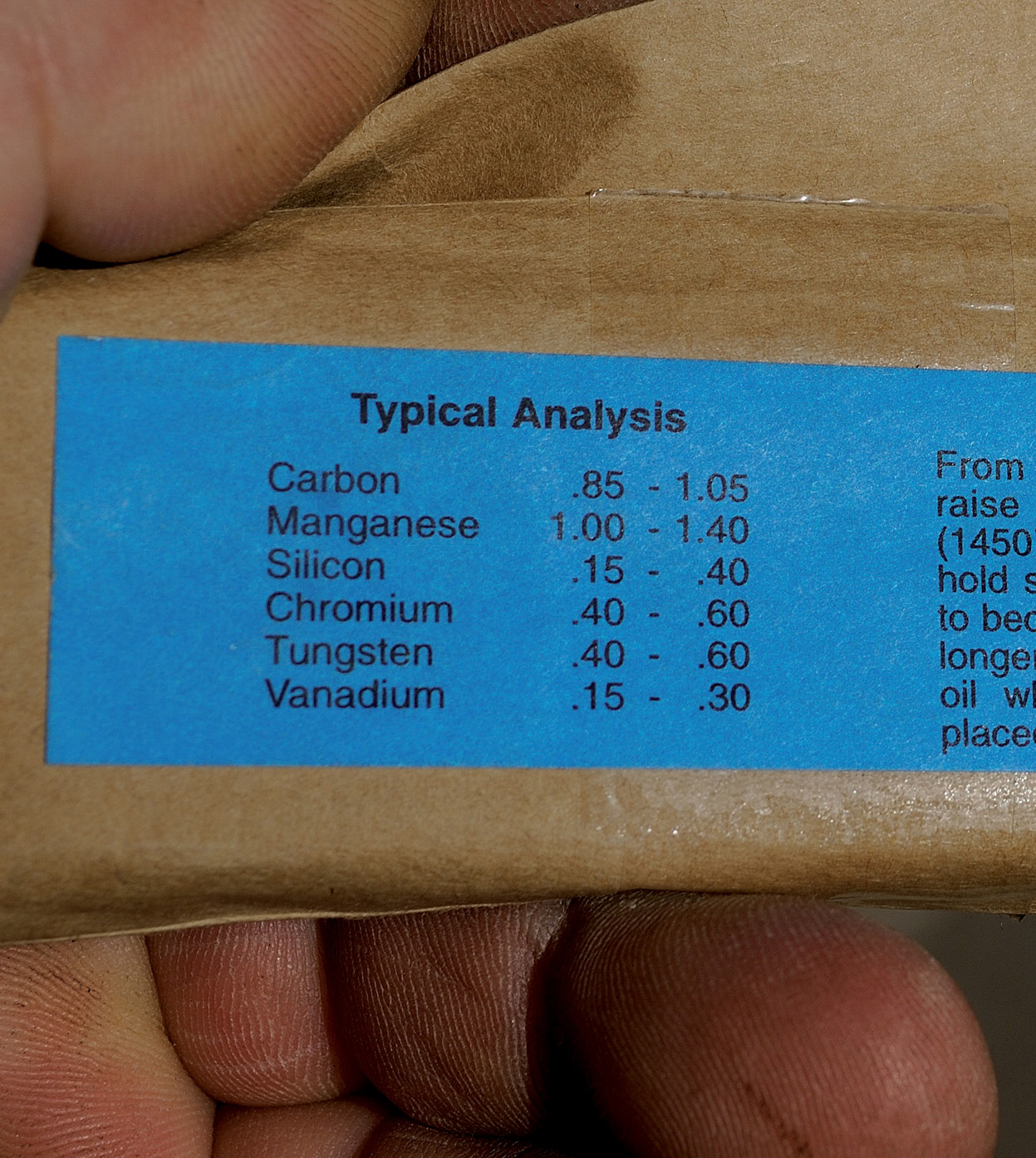

A typical steel specification on the wrapping sheet, in this case O1 gauge plate.

Steels such as mild steel that have a low percentage of carbon as an alloying element are not hardenable as they are, but by allowing carbon to come into contact with the steel at red hot temperatures, a shallow surface region with a high enough carbon content can be produced. This thin layer can then be hardened, giving a hard-wearing surface, while the main body remains relatively soft. The process using case hardening compounds and flame hardening will be demonstrated. Another use for case hardening is to produce a decorative surface often used on guns and knives called colour case hardening and this will also be demonstrated.

Most metal when worked will work harden to a certain degree. If you continue to work the metal once it has hardened, cracks will inevitably form, rendering whatever you are making into scrap. The process of annealing and normalizing materials will be discussed and how to avoid melting items made from aluminium, which goes from solid to liquid when heated without the change in colour associated with other materials. Once annealed, further work can then be resumed on soft material.

Metal Properties

Although this book is about heat treatment in the home workshop in general, the vast majority of treatments will concern steel alloys and in this chapter I will try to unravel some of the mysteries of this wonderful, but very common, alloy used in myriad places and all walks of life. Since the beginning of the Iron Age when man first discovered that by heating certain rocks to a high enough temperature, probably by accident in the first place, a metal was produced that was in many ways better than what had been found before. Copper, along with its alloys of brass and bronze, as usable materials have been around a lot longer than iron and its alloys. Tools had been made from these alloys and were very successful, the biggest drawback being that they did not keep a keen edge for long. Once iron was discovered most cutting tools were made from iron and more latterly steel alloys. The only exception to this is the use of tools in an environment where sparks could cause a safety issue. Here bronze is used instead as it does not produce sparks if hit, similar to hardened steel under the right circumstances.

CRYSTAL STRUCTURE

Any metal whether ferrous, iron or steel, or non-ferrous aluminium, copper, brass, etc. has a base characteristic that is more or less predetermined by the way the atoms and molecules in the metal structure are arranged and how they are bonded together. If you alter one, say hardness, as this increases by whatever means, usually by heat or mechanical working, the ductility will decrease as a result. Ductility, along with malleability, is the property that allows the metal to be worked without breaking. Avoiding getting too bogged down in structures at atomic level, it is the metallic bond that allows the free valence electrons to be shared between atoms; this allows the metal particles to slide over one another, rather than to snap apart as in other bond structures.

Next page