Chris Hackett - The Big Book of Maker Skills: Tools & Techniques for Building Great Tech Projects

Here you can read online Chris Hackett - The Big Book of Maker Skills: Tools & Techniques for Building Great Tech Projects full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2014, publisher: Weldon Owen, genre: Home and family. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:The Big Book of Maker Skills: Tools & Techniques for Building Great Tech Projects

- Author:

- Publisher:Weldon Owen

- Genre:

- Year:2014

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

The Big Book of Maker Skills: Tools & Techniques for Building Great Tech Projects: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "The Big Book of Maker Skills: Tools & Techniques for Building Great Tech Projects" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

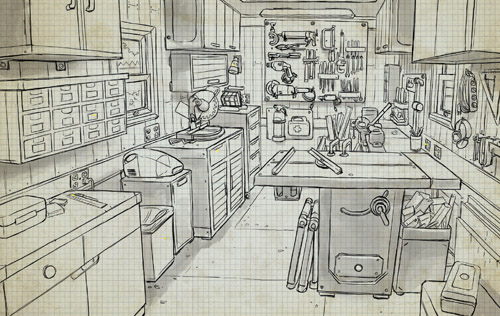

Makers, get ready. This is your ultimate, must-have, tip-packed guide for taking your DIY projects to the next levelfrom basic wood- and metalworking skills to plugged-in fun with power tools, from cutting-edge electronics play to 3-D printing wizardry. Join Chris Hackett, Popular Science intrepid DIY columnist and star of the Science Channels Stuck with Hackett, on a rummage through the toolbox of yoreand a foray into the technologies of the future.

HAND TOOLS

A classic is a classic for a reason. Learn to build your own metal forge, screen-print whatever you want, swing a hammer better than your ancestors, and repurpose what Hackett calls obtainiumbut what others might call trashinto your own mad-scientist creations.

POWER TOOLS

Discover the supreme joy that is angle-grinding, rig your own welding machine out of a junked car battery or three, and meet and master a whole host of electronic gadgetsLEDs, piezo buzzers, solar panels, and more.

ROBOTS & BEYOND

When it comes to making, theres a whole new skillset in town. Get started with CNC milling, laser-cutting, programming microcontrollers, and 3D printing in a chapter thats all about building whats next.

MUCH MORE

Setting up a hackerspace, drones and space exploration tools, circuitry basics, sourcing and crowdsourcing and biotechnology- just to name a few more. You name it; its probably in this book.

Chris Hackett: author's other books

Who wrote The Big Book of Maker Skills: Tools & Techniques for Building Great Tech Projects? Find out the surname, the name of the author of the book and a list of all author's works by series.

- and

- and  -inch (14.25- and 16-mm) ones.

-inch (14.25- and 16-mm) ones.