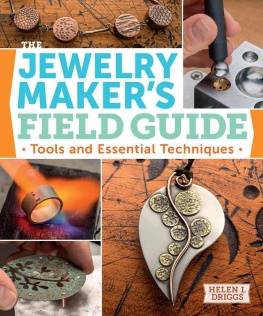

THE

JEWELRY MAKERS

FIELD GUIDE

Tools and Essential Techniques

HELEN I. DRIGGS

CONTENTS

PROJECT ONE: Leaf Brooch with Saw-Pierced Fretwork

Combine Building Blocks One, Two, Three, and Five

PROJECT TWO: Multilayered Riveted Pendant with Micro-Hardware

Combine Building Blocks Three, Four, and Five

PROJECT THREE: Suite of Soldered Stack Rings from Milled Silver Stock

Combine Building Blocks Four, Six, Seven, Eight, and Ten

PROJECT FOUR: Soldered Bead Collection on Fabricated Paddle Chain

Combine Building Blocks Six, Seven, and Eight

INTRODUCTION:

How to Use This Book

This is a book about jewelers tools and the many and varied techniques connected with each. All artists have their own preferences. Some tools are general and universal: typically, every jeweler owns a saw, files, torch, flex shaft, and a few basic hammers. After that, each individual artists tool choices relate to the work he or she prefers to create.

ADD ONE TOOL AT A TIME

It can be quite expensive to outfit a workshop fully. Most often, tools are added to an artists shop on an as-needed basis. My own workshop has taken nearly a decade to equip, and there are still several pieces of equipment I do not yet own. The best advice I can offer about tools is to purchase only what you need as you need it. Spend wisely on your tools, use them for some time to become familiar with them before you buy more tools, and save money for metalotherwise, you will have nothing on which to use those tools.

LEARN IN STAGES

I have organized this book in the sequence a first-year metals student would learn the craft. It is ordered by tool and material categories, which are illustrated and for which I describe their various uses. Cross-references throughout the text will guide you to related information. It is important for you to understand what a tool is used for, as well as how to use it correctly to protect both yourself and the tool.

Patience and willingness to practice are perhaps the two most important skills for an aspiring jeweler to learn. Take time to read each section and work slowly, patiently, and carefully. Following the applied techniques will familiarize you with a particular tool group. Then you will practice using the tool in a guided lesson. Both your hands and your eyes will become educated and more precise as you work through the lessons. If you dont get something the first time around, try again.

Making jewelry is fun: it is easy to be swept away by your enthusiasm. The tendency to rush work to completion is difficult to control; but well-made, beautifully finished, and aesthetically pleasing jewelry takes time to create. There are no shortcuts. Put the thought of jewelry to wear out of your head and focus instead on each task in its turn. Such discipline will help you control the desire to rush before you should. The reward for your patience will be an enduring object of beauty and, ultimately, mastery of the skills you need to create many more.

Learn from Front to Back

Follow the first eight building blocks in this book and you will develop the foundation skills you need for a long and fascinating trip through the process of jewelry making. I recommend that you try every set of applied techniques in the order they are presented, as each builds important skills for you that are interconnected.

BUILD A FOUNDATION

Some areas of technique will appeal to you more than others: this is natural. But it is important to develop the skill sets presented in each of the first eight building blocks before you mix them up into functional forms of your own design. As you practice, you will see improvements in your skills. So save your early attemptsnothing is more satisfying than witnessing your own evolution.

Work hard, work safe, and may the gods of metal smile upon you!

PART ONE:

Raw Materials

Cross-reference:Universal Gauge Chart,

When it comes to which metal you choose for making jewelry, there are so many options. You can construct wearable art from precious and base metals and their alloys, ferrous or nonferrous metals, and recycled or reclaimed metals.

JEWELRY METALS AND ALLOYS

Each type of metal has its own advantages and limitations: a property that presents an insurmountable problem for one artist may be chosen by another for this very property. Do not let the potential difficulty of using a particular metal dissuade you from using it, because creative or innovative design solutions typically emerge from working around a problem. Every material has the potential to become an interesting ingredient in studio jewelry.

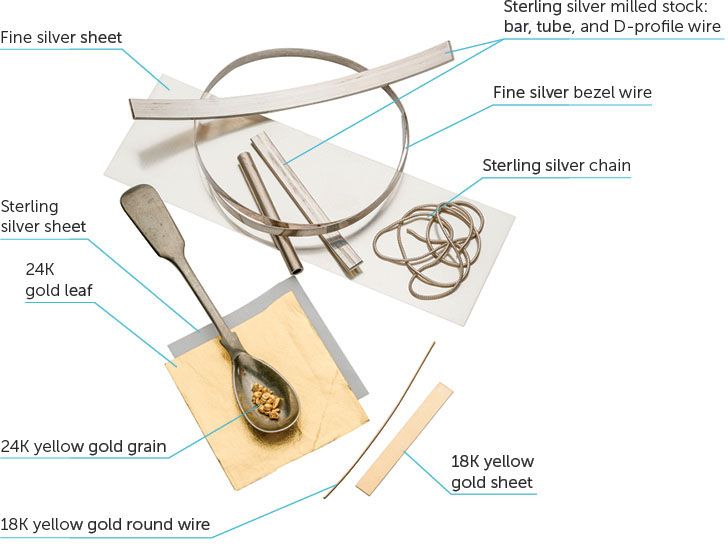

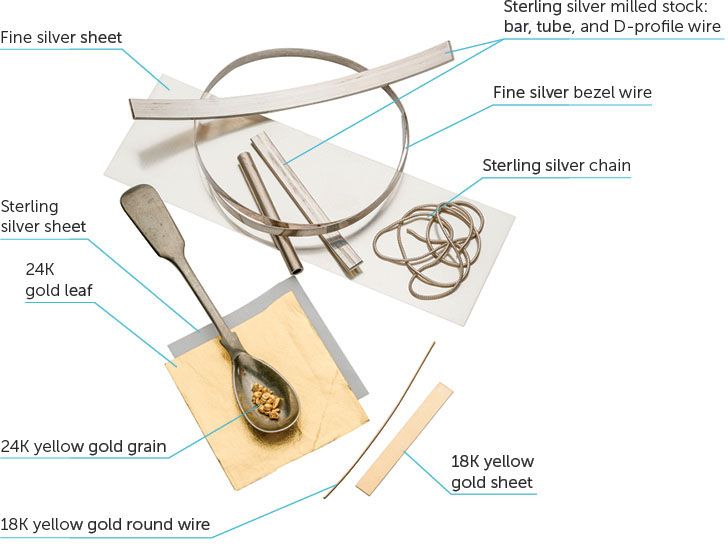

Proper studio material management in the beginning will pay off in the long run. So take the time to document and label everything as you acquire it to avoid costly errors once you get caught up in the work. It is important to store and label all metal by recording the material, price paid, and source, especially for alloys. Many metals look similar and are easy to confuse when they are placed side by side. However, each supplier or mill has a proprietary recipe for each metal alloy it produces, which may or may not be evident until the metals are worked.

When you purchase metal from the mill or supply house, you will need to decide on three things:

- type of metal

- form of the metal: gauge or shape

- dimensions or weight of the metal

Depending on the supplier and the metal, the costs are tied to fluctuations of the daily metals market prices. Once you have chosen your metal type and decided how much of it you want, youll multiply its weight by the spot price for that day.

When purchasing metal, it is important to ask what the daily price is. A supplier will either add in or subtract out of the advertised base price relative to the actual daily priceor, spot priceat that moment or on that day.

Most suppliers offer a cutting service for stock or sheet and will charge a nominal per-cut fee to subdivide the purchased metal into smaller dimensions once you have purchased the minimum size. It is often well worth paying a cutting fee for small or oddly shaped subdivisions of sheet because you will save time in doing so.

Types of metals

NOBLE or PRECIOUS METALS are lustrous and very resistant to corrosion and oxidation. In the jewelry industry, they are typically referred to as precious metals and include gold, platinum, and silver. Other precious metals include members of the platinum group: ruthenium, rhodium, palladium, osmium, and iridium, some of which are used in precious-metal alloys and for plating sterling silver to reduce tarnishing.

Noble Metals

FERROUS METALS contain iron or steel. Historically, they were not often used for making jewelry up until the industrial revolution, when they were introduced in the mass manufacture of costume jewelry components and as completed jewelry pieces. Since the 1970s, both iron and steel have become more commonly used in studio jewelry, particularly iron and stainless steel. Hot-forged iron or steel is worked using blacksmithing techniques, while stainless steel is machined or milled because it is extremely hard to fabricate using only hand tools. Both iron and steel are difficult to join by