ACKNOWLEDGMENTS

To my father, Jerry, who taught me always to watch and listen; and to my daughter, Josephine, who stands on her grandfathers shoulders watching, listening, and learningand teaching all of us.

I would also like to acknowledge the untiring support of my partner Kathy Tam and the helpful guidance of technical editor Rick Mastelli, which made this book possible.

All illustrations by Scott Wynn.

Photos by Rick Mastelli, Scott Wynn, and Jon Deck.

CONTENTS

INTRODUCTION

CHAPTER 1:

What to Use, When, and Why

The Challenge of Grit

CHAPTER 2:

The Cutting Edge

Sharpening versus Re-Sharpening

Anatomy of Steel

Steel Grain

The Ideal Edge

Disston Saws

Hardening, Tempering, and Annealing

Types of Edge Steel

Alloy Ingredients

Forgeability

CHAPTER 3: FOR

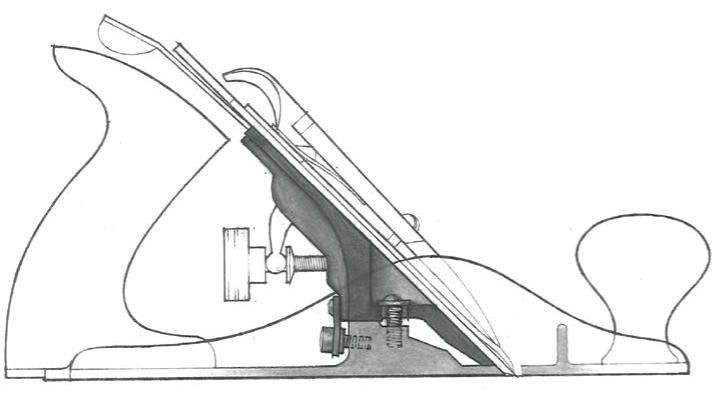

Understanding How a Plane Works

The Angle of the Blade

Pitch Angles

Use the Lowest Effective Cutting Angle

Why 45?

Cutting Angles for Different Woods

Cutting End Grain

Blade Steels for Different Woods

Molding Planes

Mouth Opening

Chipbreaker

Plane Geometry, a Summary

Hard Chipbreakers

Millers Falls Lever Cap

Bevel Angle

The Correct Bevel Angle

Shape of the Blade Edge

How an Edge Dulls

Length of Plane/Width of Blade

Honing a Hollow-Ground Bevel

The Proportion of Length to Width

How Flat is Flat

CHAPTER 4:

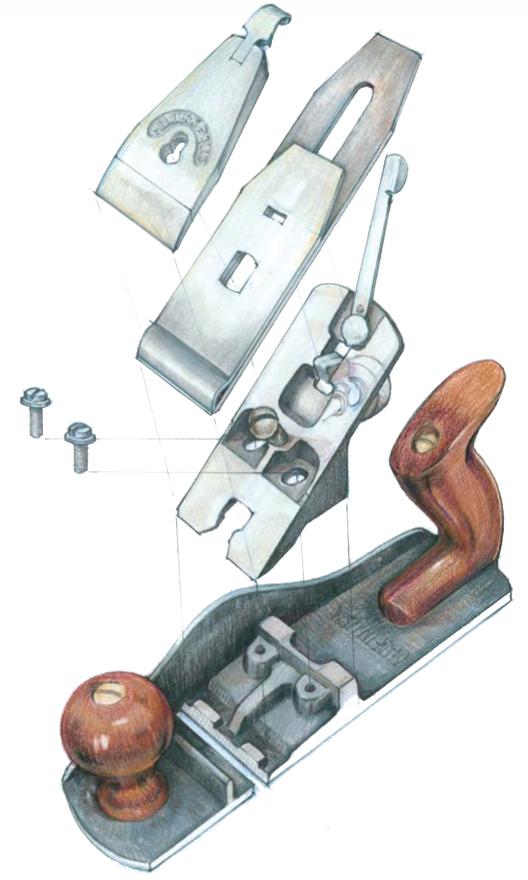

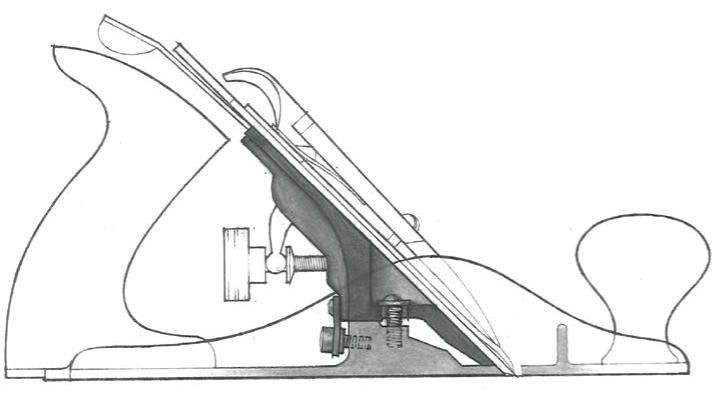

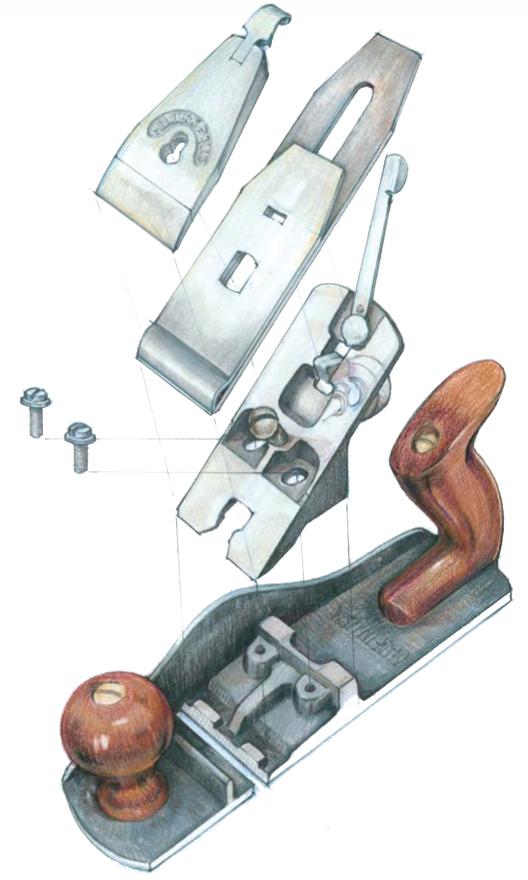

Understanding How the Stanley/Bailey Plane Works

The Bevel-Down Planes

The Adjusters

The Oiler

The Bevel-Up Planes

CHAPTER 5:

Traditional Solutions: the Jack, Jointer, and Smoothing Planes

The Jack Plane

The Fore Plane

The Jointer Plane

Trying, Long, and Jointer

The Correct Blade Shape

Smoothing Planes

The Ideal Edge Shape

Why a Narrow Smoother?

CHAPTER 6:

A Guide to a Suitable Toolkit

First Things First

Adjustable Throat Plates

Beyond the Basics

CHAPTER 7:

Setting Up the Bailey/Stanley Plane

Flattening the Back of a Plane Blade

Working Around the Blade-Adjustment Nib

General Techniques for Adjusting the Plane Blade

What Really Happens

A Scraper for Metal

Gauging Straightness

File Mouth Relief

Avoid Distortion

Mouth Going Out of Parallel

Adjusting the Bailey-style Plane

Setting Up a Used #6 Fore Plane

Setting Up the Stanley #60

Adjusting the Throat

Setting Up Rabbet Planes

Setting Up a New Stanley #60

Troubleshooting

Keep Your Eyes on the Prize

Keep the Surface Flat

CHAPTER 8:

A Basic Skill that Leads to Others

Bevel Shape

Grinding

Grinding Out a Nick

Grinding on a Sanding Belt

Sharpening Stones

Stone Choices

Diamond Stones

Using and Maintaining Waterstones

Technique

Listening

Sharpening

CHAPTER 9:

Of Slaves, Dogs, and Deadmen

A Simple Bench

Shooting an Edge

Winding Sticks

Techniques for Shooting an Edge

CHAPTER 10: &

Invaluable, Often-Overlooked Tools

Bench Hook versus Shooting Board

INDEX

INTRODUCTION

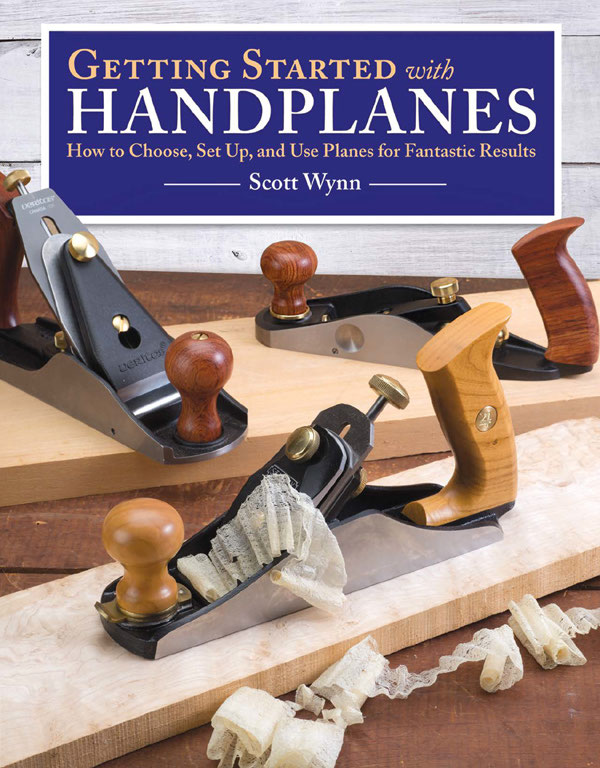

I cannot think of anyone who has made a shaving with a plane and not been seduced by the sight, sound, and feel of the shaving emerging from the top. It is a tool of enormous satisfaction. However, it is far more than the pleasure of using a plane that makes it important. The handplane quickly and effectively does things other tools cannot. Power tools have redefined and often supplanted the handplanes traditional role, but have not replaced it. Understanding the handplane (how to set it up, fine-tune it, and adjust and modify its anatomy) and the variety of jobs it handles increases options for work and efficiency and improves results, allowing you to experience the satisfaction this essential tool brings.

THE OF

A machine might best accomplish a repeated task (you decide how many justifies automation), but hand tools can efficiently assist or accomplish short runs, one-of-a-kind pieces, prototypes, and variations on a theme. I find one of the main advantages to a proficiency with hand tools is fewer limitations in the types of projects I am able to tackleprojects otherwise too small or too big, projects too complex, and projects whose form is evolving even as theyre being produced. Even if you are working in production or large millwork situations, handplane skills can be a godsend.

In addition to extending the range of projects you can tackle, the handplane is demonstrably faster for some tasks, including smoothing small parts. A well-set handplane can smooth a side of a leg, for instance, smoother than 1,000-grit sandpaper in two or three strokes, with none of the rounding or waviness you might get with sanding. A few strokes of a handplane can likewise remove the saw marks and tearing you get on end grain. A follow-up of a few strokes with 220-grit sandpaper and you get quick, baby-bottom smoothness. The best tool to remove snipe and power-planer variations is the handplane, as its flat sole flattens the board in removing the snipe. It is fast, and it is accurate.

The results you get with a handplane are different from those with sandpaper. Assuming the blade is correctly shaped, a handplaned piece is going to be flatter and straighter than all but the work produced with the best wide-belt sanders. Less expensive wide-belt sanders can leave ripples similar to a planer. Belt and orbit sanders leave a gently wavy surface like calm water that shows up especially after applying finish, on horizontal surfaces. If you have a flat-grain piece, say in oak or pine, sanding removes more softer spring growth than denser late-season growth, resulting in a gently rippling surface following the grain. This will not happen with a handplane. Power sanding, particularly with the random-orbit sander, tends to slightly round over work in general, but especially smaller pieces, sometimes giving the work a doughy look. Handplaning also provides a better surface for gluing.