Introduction

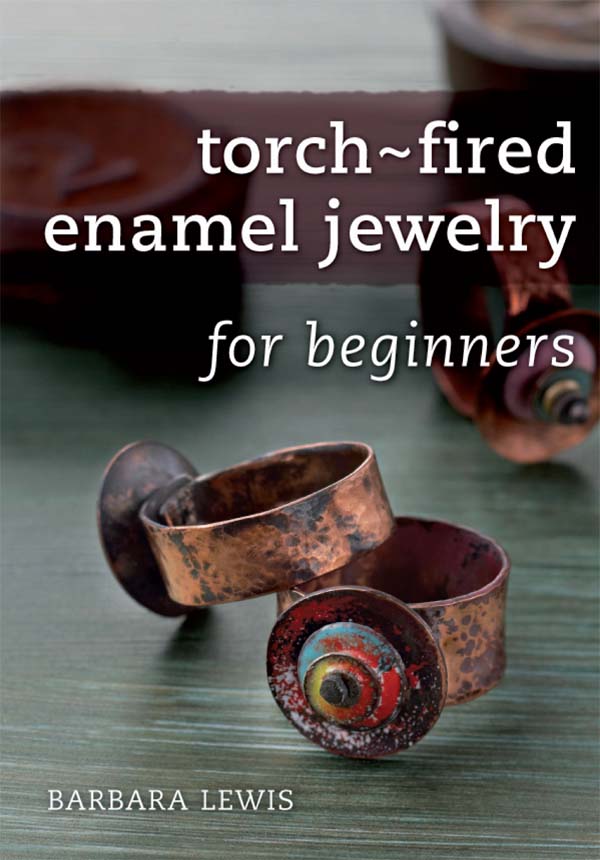

Do you love the look of enamel pieces in jewelry but youve been discouraged from making them because of the tedious and labor-intensive process? Maybe youre turned off by the investment in a kiln and the associated tripods and other supports. Or perhaps you are daunted by the fussiness of cleaning copper and washing and sifting enamels.

What if I told you that torch-fired enameling can solve all of these problems? That, for an investment of about $100, you could get all the necessary equipment for a start-up enamel studio, including a torch, several enamel colors, beads and bits of copper? That you didnt have to wash or sift enamels or scrub metal? Better yet, that, as a beginner, you could enamel sixty beads in an afternoon?

Well, that is what Im telling you! No kidding!

Even beyond the initial excitement over its affordability and spontaneous approach, torch-fired enamel offers much creative potential. You can manipulate pieces in the open flame to produce enamel flows or burnt edges. You can coax pink and golden flashes to the surface of a piece by manipulating the balance of oxygen and fuel. Want a smoky haze over there, right next to that hole you punched? Go for it! Torch-fired enameling gives you creative control.

From the minute you place a bead or pendant on your mandrel, you are making design decisions. You are intimately involved with your work. Your pieces never leave your sight to go into a kiln. Your approach is fluid, and your design decisions can be either spontaneous or planned.

What happens if you dont like the end result? Just re-fire it! Yes, you can do that, too! There are very few times in life when you get a do-over, but youve just found one of them!

Did I mention that its also fun? Its the kind of fun that encourages play in the studiothe play of exploration! It was during a play session in the studio that I developed a heat rivet for delicate enamel. No hammering on glass required. Maybe youre interested in making bezels without solder, or making unique, etched beads from copper pipe. Its all here, between the front and back covers of this book!

My first goal is to get you comfortable with the open flame of a torch. Well explore the types of enamels, their colors, and ways to modulate color. Well discuss suitable metals that work with enamel. We will then combine this knowledge with some simple metalworking skills to create masterpieces. Using the projects in this book, you will develop a personal repertoire of design techniques that are not only successful, but will also appeal to your unique aesthetic.

The Japanese have an expression, shibui, which means happy accident. I have had many happy accidents in the studio, like the time I was at the potters wheel and trimmed through the bottom of a ceramic platter only to create a mirror frame. I knew an old-time carpenter who expressed the concept of shibui in another way. He would say it was when an accident works in your favor.

For me, shibui is when something is perfectly imperfect. It is the triumph of personality over perfection. It is when the pressure is off and we allow ourselves to play without qualification or judgment. It is when things click, when they feel right, and when we have the most intimate connection to our work. Can you recapture the days when play was your work, the work of the innocent? This is my invitation to you.

Torch-Firing Techniques

Forty years ago, Joseph Spencer of Safety Harbor, Florida, grew tired of the tedious and time-consuming methods of kiln-firing enamel. Through trial and error, he created a unique firing process using a simple, affordable torch. Current conventional methods of torch-firing call for sifting the enamel on metal. The metal is stationary and you move the torch by hand. Flip this process upside down and you get Joes method. The torch is stationary and you move the metal. A bonus is that there are much fewer airborne enamel particles.

Add this technique to my ceramics education and nearly twenty years of experience with firing gas kilns, and you get the Painting with Fire method, which encourages artistic interaction between the enamelist, the work and the flame. In a nutshell, this technique involves placing a metal bead on a stainless steel mandrel, heating the bead until it glows bright orange, and dipping the bead into enamel. Perform this process two or three times and you have created a little masterpiece!

All of the projects in this book are fired with an inexpensive torch. It is not necessary to have anything more. However, if youre a lampworker and have a torch that mixes oxygen with propane, methane or natural gas, youre all set. You can incorporate this technique into your glass beadmaking workflow with nary a hiccup.

METAL: THE OBJECT OF MY ATTRACTION

The definition of enamel is glass on metal, but what kind of metal are we using? Copper, silver and gold are traditional metals for enameling, but you need not limit yourself to these metals. By trial and error, I found that the metal beads I had in my studio not only withstood the heat of the torch, but provided a successful base onto which the enamel could fuse. I remembered that these beads were made from iron. With magnet in hand, I began to scan the depths of bead racks at craft stores, bead shops and flea markets for suitable beads.

Keep in mind that just because a bead is attracted to a magnet doesnt necessarily mean that it will enamel beautifully. Experiment with one before you buy five hundred. If a metal bead withstands the heat without melting, enamel it. Wear the bead around and watch for chipping. Of course, if you want a sure thing, buy silver, copper or gold. Iron is a lot less expensive, though, and I like to be a little less traditional!

What is Depletion Gilding?

Depletion gilding involves heating sterling silver to a dull cherry red so the copper oxides come to the surface and darken the sterling. Next, the sterling is placed in pickle, a mild acid, to remove the oxidation. This process is repeated about ten times, or until the sterling no longer darkens with copper oxides when heated. The copper has been depleted from the metal, and you are finally ready to enamel it. Gosh, that sounds like a lot of work!

Brass is not a recommended metal, which is really a shame because there is such neat stuff in brass. It is the zinc in brass that is the troublemaker; enamel will not adhere to brass because of the zinc. The zinc content in a metal needs to be less than five percent in order for the enamel to adhere. Since brass is an alloy, we cant guarantee the metal composition.

While were talking about caveats, also avoid copper beads that use high-zinc solder at the nearly invisible seams. You may want to ask your bead merchant about how the bead was constructed before buying it.

Sterling silver is a precious metal that shimmers beautifully under transparent enamel. Add a hammered texture to the sterling, and the light reflecting off the facets makes the piece even more brilliant. Enamelists working in the tradition of cloisonn will tell you that you must depletion-gild the sterling before it is enameled. When you spend countless hours on a piece and youre working with pinks and purples, which can be persnickety, you want your colors to be as true as possible. So, by all means, do what you feel is necessary.