U.S. ARMY GUIDE

TO RIGGING

U.S. ARMY GUIDE

TO RIGGING

DEPARTMENT OF THE ARMY

Copyright 2013 by Skyhorse Publishing, Inc.

No claim is made to material contained in this work that is derived from government documents. Nevertheless, Skyhorse Publishing claims copyright in all additional content, including, but not limited to, compilation copyright and the copyright in and to any additional material, elements, design, or layout of whatever kind included herein.

All Rights Reserved. No part of this book may be reproduced in any manner without the express written consent of the publisher, except in the case of brief excerpts in critical reviews or articles. All inquiries should be addressed to Skyhorse Publishing, 307 West 36th Street, 11th Floor, New York, NY 10018.

Skyhorse Publishing books may be purchased in bulk at special discounts for sales promotion, corporate gifts, fund-raising, or educational purposes. Special editions can also be created to specifications. For details, contact the Special Sales Department, Skyhorse Publishing, 307 West 36th Street, 11th Floor, New York, NY 10018 orinfo@skyhorsepublishing.com.

Skyhorse and Skyhorse Publishing are registered trademarks of Skyhorse Publishing, Inc., a Delaware corporation.

Visit our website at www.skyhorsepublishing.com.

10 9 8 7 6 5 4 3 2 1

Library of Congress Cataloging-in-Publication Data is available on file.

ISBN: 978-1-61608-876-7

Contents

DISTRIBUTION RESTRICTION: Approved for public release; distribution is unlimited.

* This manual supersedes TM 5- 725, 3 October 1968.

List of Figures

List of Tables

Preface

This manual is a guide and basic reference for personnel whose duties require the use of rigging. It is intended for use in training and as a reference manual for field operations. It covers the types of rigging and the application of fiber rope, wire rope, and chains used in various combinations to raise or move heavy loads. It includes basic instructions on knots, hitches, splices, lashing, and tackle systems. Safety precautions and requirements for the various operations are listed, as well as rules of thumb for rapid safe-load calculations.

The material contained herein is applicable to both nuclear and nonnuclear warfare.

The proponent for this publication is Headquarters (HQ), United States (US) Army Training and Doctrine Command (TRADOC). Users of this manual are encouraged to submit recommended changes or comments on Department of the Army (DA) Form 2028 and forward them to: Commandant, US Army Engineer School, ATTN: ATSE-T-PD-P, Fort Leonard Wood, Missouri 65473-6500.

Unless otherwise stated, masculine nouns and pronouns do not refer exclusively to men.

CHAPTER 1

Rope

Section 1. Fiber Rope

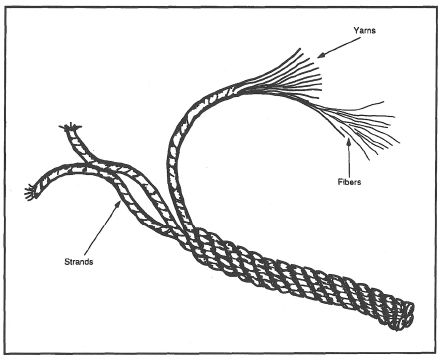

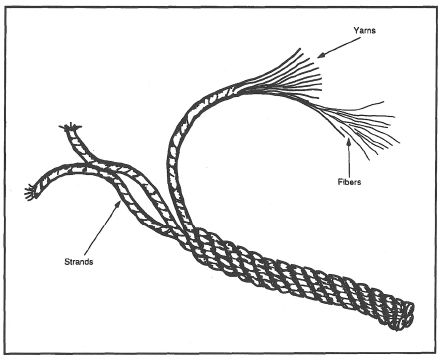

In the fabrication of fiber rope, a number of fibers of various plants are twisted together to form yarns. These yarns are then twisted together in the opposite direction of the fibers to form strands (see , page 1-2). The strands are twisted in the opposite direction of the yarns to form the completed rope. The direction of twist of each element of the rope is known as the lay of that element. Twisting each element in the opposite direction puts the rope in balance and prevents its elements from unlaying when a load is suspended on it. The principal type of fiber rope is the three-strand, right lay, in which three strands are twisted in a right-hand direction. Four-strand ropes, which are also available, are slightly heavier but are weaker than three-strand ropes of the same diameter.

TYPES OF FIBERS

The term cordage is applied collectively to ropes and twines made by twisting together vegetable or synthetic fibers.

VEGETABLE FIBERS

The principal vegetable fibers are abaca (known as Manila), sisalana and henequen (both known as sisal), hemp, and sometimes coir, cotton, and jute. The last three are relatively unimportant in the heavy cordage field.

Abaca, sisalana, and henequen are classified as hard fibers. The comparative strengths of the vegetable fibers, considering abaca as 100, are as follows:

| Sisalana | 80 |

| Henequen | 65 |

| Hemp | 100 |

Manila

This is a strong fiber that comes from the leaf stems of the stalk of the abaca plant, which belongs to the banana family. The fibers vary in length from 1.2 to 4.5 meters (4 to 15 feet) in the natural states. The quality of the fiber and its length give Manila rope relatively high elasticity, strength, and resistance to wear and deterioration. The manufacturer treats the rope with chemicals to make it more mildew resistant, which increases the ropes quality. Manila rope is generally the standard item of issue because of its quality and relative strength.

Sisal

Sisal rope is made from two tropical plants, sisalana and henequen, that produce fibers 0.6 to 1.2 meters (2 to 4 feet) long. Sisalana produces the stronger fibers of the two plants, so the rope is known as sisal. Sisal rope is about 80 percent as strong as high quality Manila rope and can be easily obtained. It withstands exposure to sea water very well and is often used for this reason.

Figure 1-1. Cordage of rope construction

Hemp

This tall plant is cultivated in many parts of the world and provides useful fibers for making rope and cloth. Hemp was used extensively before the introduction of Manila, but its principal use today is in fittings, such as ratline, marline, and spun yarn. Since hemp absorbs much better than the hard fibers, these fittings are invariably tarred to make them more water-resistant. Tarred hemp has about 80 percent of the strength of untarred hemp. Of these tarred fittings, marline is the standard item of issue.

Coir and Cotton

Coir rope is made from the fiber of coconut husks. It is a very elastic, rough rope about one-fourth the strength of hemp but light enough to float on water. Cotton makes a very smooth white rope that withstands much bending and running. These two types of rope are not widely used in the military; however, cotton is used in some cases for very small lines.

Jute

Jute is the glossy fiber of either of two East Indian plants of the linden family used chiefly for sacking, burlap, and cheaper varieties of twine and rope.

SYNTHETIC FIBERS

The principal synthetic fiber used for rope is nylon. It has a tensile strength nearly three times that of Manila. The advantage of using nylon rope is that it is waterproof and has the ability to stretch, absorb shocks, and resume normal length. It also resists abrasion, rot, decay, and fungus growth.

CHARACTERISTICS OF FIBER ROPE

Fiber rope is characterized by its size, weight, and strength.

SIZE

Fiber rope is designated by diameter up to 5/8 inch, then it is designated by circumference up to 12 inches or more. For this reason, most tables give both the diameter and circumference of fiber rope.

WEIGHT

The weight of rope varies with use, weather conditions, added preservatives, and other factors. , page 1-4, lists the weight of new fiber rope.

STRENGTH