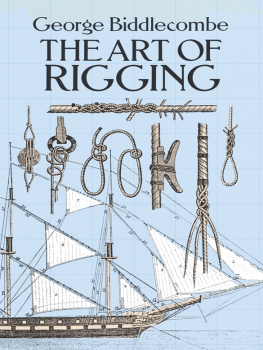

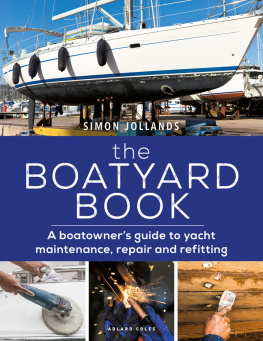

The rig is your yachts engine. It consists of the mast, spreaders, stays and shrouds with deck and mast fittings, boom, spinnaker or gennaker pole, halyards, sheets, control lines, blocks, winches, cleats, sails and often useful extras such as a roller reefing system or a fixed boom vang. If nothing else, this list shows that your boat does not sail unaided. Your engine will only deliver maximum power when all the parts are properly geared to one another, when they are in their proper place and optimally tuned, and when all the moving parts run smoothly. The designer has done a lot of thinking and calculating to find the best possible arrangement of high quality materials and fittings for your boats rigging. Nevertheless, you may still end up facing a number of issues, for example when you want to step the mast after winter storage, replace worn parts, or loosen a jammed drum or sheave. This book will not only help you to find answers and solutions, but also prevent problems and make improvements. By means of explanations, photos, drawings, checklists, step-by-step instructions and clever tips, all the relevant aspects of masts and standing rigging, including tuning, are discussed in detail.

Rigging

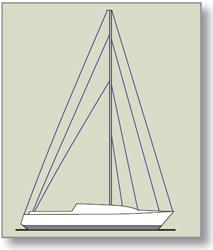

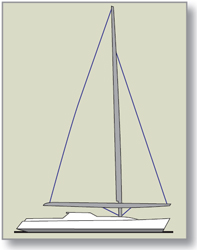

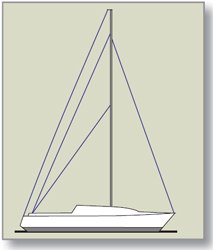

A masthead rig has the forestay, backstay and cap shrouds (side stays), all attached at the masthead. Then there can be many variations in length and mounting positions of further standing rigging inner forestay, babystays, intermediate shrouds and lower shrouds depending on the design of the rig, the mast material (wood, aluminium or composite) and the mast profile (section) and its dimensions. The masthead rig has considerable stiffness and adjustment to the prevailing weather conditions can only be achieved by means of sail selection.

Rigging

The function of stays goes much further than just holding the mast up they also ensure:

that the mast does not bend sideways (athwartships) |

athwartships centring of the masthead |

optimal fore and aft rake for a balanced rudder (weather helm) |

the desired mast trim under sail |

the amount of pre-bend needed to fit the mainsail profile |

the stability of the mast section (more sets of spreaders and more shrouds enable the mast to have a smaller profile) |

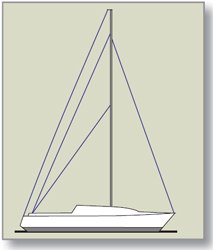

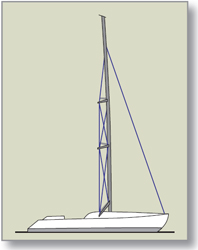

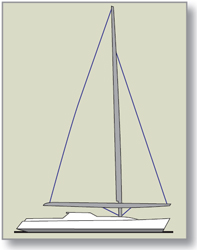

When the forestay is mounted below the masthead it is termed a fractional rig. The commonest types are 3/4, 7/8 and 9/10 rigs most (older) one-design classes are 3/4-rigged. Designers do not take these numbers too literally; other ratios (up to 19/20, i.e. virtually masthead) are also found among fractional rigs. Tall or relatively light masts also feature running backstays attached to the mast at the same height as the forestay. Sometimes a second set of running backstays is mounted further down. Compared to masthead rigs, the mast tuning options on a fractionally rigged boat are much better, because the extent of mast bend fore and aft is greater.

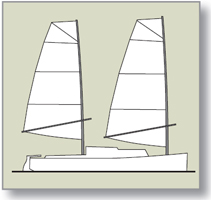

There are also more unusual rigs to be found, such as the Aero rig for example, where the pivoting mast forms a whole with a boom that continues forward of the mast to which only a forestay is attached. A BG rig (Bergstrm & Ridder) has no backstay, but the cap shrouds feature spreaders at various heights that are swept far aft in combination with intermediates mounted crosswise.

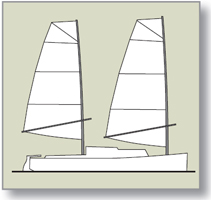

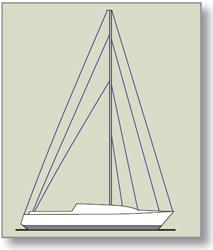

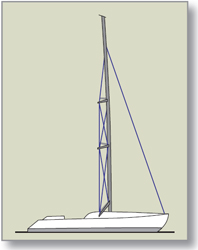

A sharpie rig is completely unstayed, bearing a strong resemblance to a sailboard rig.

Masthead Rig

Fractional Rig

Sharpie Rig

Strength

Dont think that rig design depends solely on the sail area your boat will carry. It is the boats righting moment that decides how strong the rig has to be. Mast manufacturers test the designers calculations by heeling the boat to 30. The location of the chainplates and the angle of the spreaders (straight or swept back) also play an important role.

Aero Rig

Bergstrm & Ridder Rig

Wood

Traditional yachts still use wooden masts quite a lot, although the originally massive spars have generally been replaced by glued sections or hollow profiles. The stiffness of a modern wooden mast with formed parts is in no way inferior to that of an aluminium mast. Thanks to advanced varnish systems, wooden masts now have a longer lifespan, but they require a lot of maintenance and specialised knowledge, for example, when it comes to putting on fittings or recognising the early stages of delamination due to the ageing of certain types of glue.

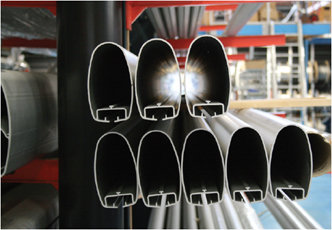

Aluminium

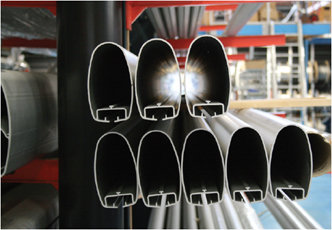

Aluminium is by far the most popular material for masts. It is available in every possible shape and is relatively easy to handle. Aluminium masts are very strong in relation to their weight, they last for years and maintenance is easy. Depending on the dimensions, the profile is extruded from one piece or composed of various preformed sections. Tracks to slide the mainsail up and down using slides or slugs can be fully countersunk into the profile. Modern aluminium masts use slender sections, but even the taller ones remain sufficiently stiff thanks to an additional inner profile.

Aluminium mast sections with tracks for slides

Composite

Particularly on racing yachts, the other important factor besides weight is the masts aerodynamic characteristics. Hence more and more masts are being made from carbon fibre, or similar materials, with which the desired characteristics, such as shape, stiffness and tapering, can be created even better than with aluminium. Production methods differ considerably. Usually the material is applied in many dozens of layers around an aluminium core that is later removed. Sometimes the mast is laminated in a mould in two halves and then glued together. The epoxy in composite masts is extremely sensitive to ultraviolet light, but as long as the protective coating remains undamaged, maintenance is simple. The composite material cannot possibly corrode, but it does not tolerate stainless steel or aluminium, so proper insulation of fittings is essential.

Production of a composite mast for a J-class yacht

Stepping

A mast is either stepped on deck or on a step placed on the keelson or on a reinforced area of the hull. A deck-stepped mast requires a special base plate (step) or a tabernacle (hinge) if the mast is to be lowered often. In that case there is usually either a mast support below deck or the main bulkhead provides the required support. A keel-stepped mast can be built lighter and offers the additional advantage that the mast foot can be moved fore and aft more easily to adjust the mast rake. All the wiring remains below deck, too, so there is no need for through-deck or swan neck fittings.