Published in 2020 by The Rosen Publishing Group, Inc.

Copyright 2020 by The Rosen Publishing Group, Inc.

All rights reserved. No part of this book may be reproduced in any form without permission in writing from the publisher, except by a reviewer.

Names: Rauf, Don, author.

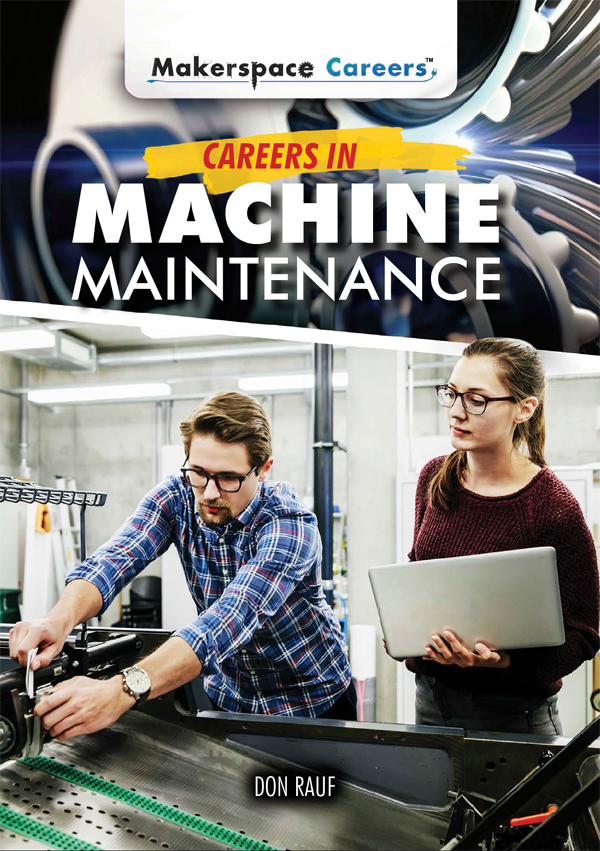

Title: Careers in machine maintenance / Don Rauf.

Description: First edition. | New York: Rosen Publishing, 2020. |

Series: Makerspace careers | Audience: Grades 712. | Includes

bibliographical references and index.

Identifiers: LCCN 2018050169| ISBN 9781508188070 (library bound) | ISBN 9781508188063 (paperback)

Subjects: LCSH: MachineryMaintenance and repairVocational guidanceJuvenile literature.

Classification: LCC TJ153 .R26 2020 | DDC 621.8/16023dc23 LC record available at https://lccn.loc.gov/2018050169

INTRODUCTION

W hat is the makerspace movement? Makerspaces are bringing people together to do hands-on creative and often technology-oriented projects. They are teaching people to build robots, fix bicycles, program gadgets, make model airplanes, use 3D printers, and more. The emphasis is on hands-on work and showing people that they can learn things that may at first seem beyond their grasp.

These makerspaces are perfect training grounds for those who want to pursue a career in machine maintenance. Machine mechanics and maintenance workers are in demand to keep all types of factory equipment and industrial machinery humming along and operating correctly. Young people can enter most of these careers with just a high school diploma, but having the hands-on experience working on repairs and fixing and building electronics, gadgets, engines, and other items can provide the real-life skills needed to be successful in this field.

Many people use electronic devices and machines, but they dont know how they operate. Maker groups give people a mindset so that they cannot only understand how things work, but they can make things themselves.

In 2018, students at the Moffitt Library Makerspace at University of California Berkeley designed a robot that could locate survivors in a disaster. A group of four students built a device that could identify human voice frequencies and then give the direction indicating where the voices were coming from. The project helped students learn some very high-tech skills about circuit design, motor controls, and algorithms.

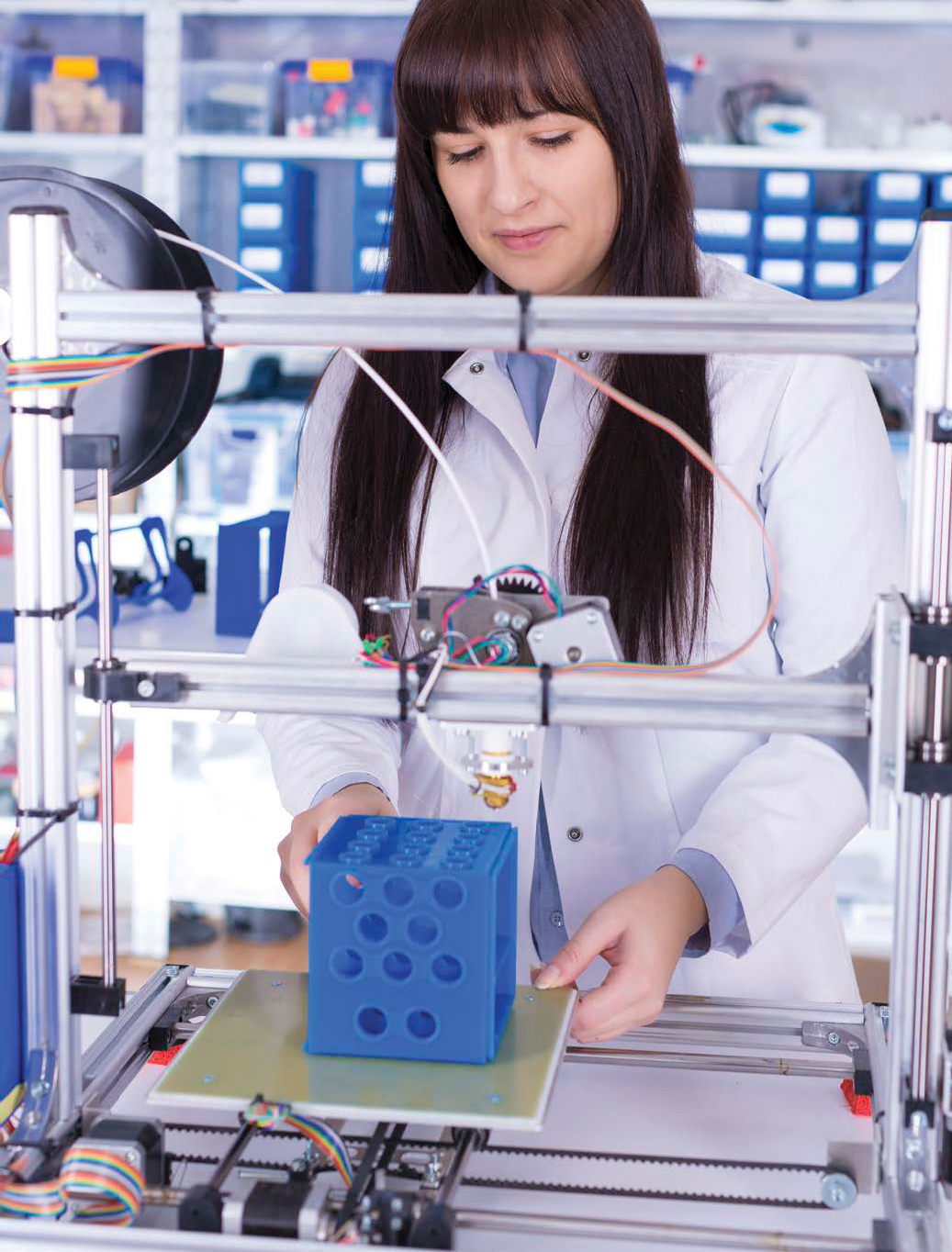

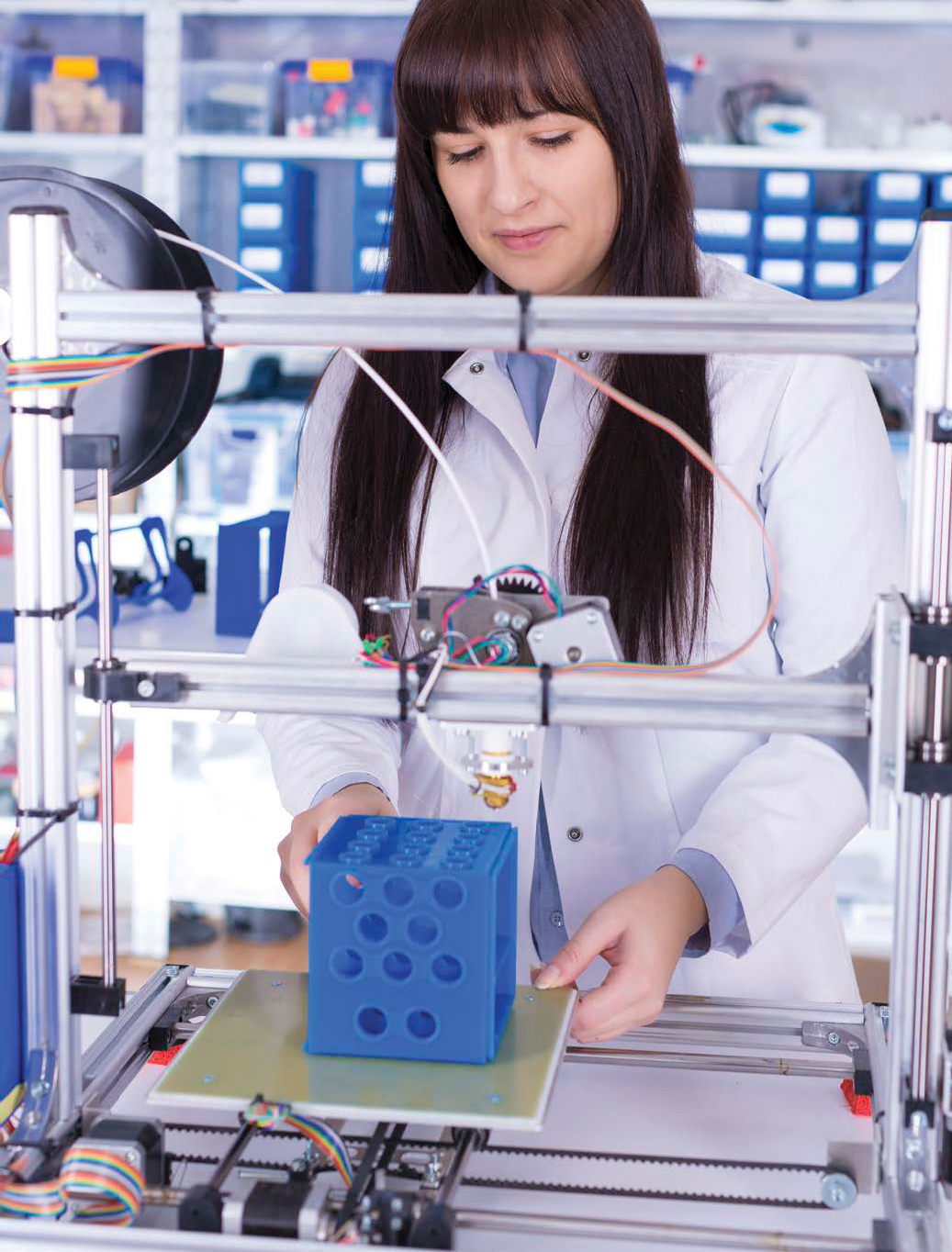

Makerspaces often give students the opportunity to create projects with cutting-edge technology, such as 3D printers, which can produce three-dimensional objects by laying down successive layers of material.

The students involved in the project said that the makerspace environment let them pool their talents, ideas, and resources. Plus the space gave them essential items like Arduino motors that run on simple computers and Raspberry Pis, which are tiny, inexpensive computers that can enable devices to perform all sorts of functions. In addition, makerspaces may provide soldering irons, wire clippers, oscilloscopes (for measuring electronic signals), and other helpful tools.

In an article in Berkeley Library News, one student maker said, People are interested in doing cool projects, where they build stuff and it moves and can solve problems. But you cant do it on your own you need a community. We get people to think about what they can make, because we have the resources for them to do it.

They sometimes take place in libraries, schools, and other spaces that available for public use. Their emphasis is on basic STEAM skills, which focus on Science, Technology, Engineering, Arts, and Math.

Makers are hobbyists, enthusiasts, and students or amateurs interested in innovation, creating new products, and producing value in the community. Through hands-on learning, makerspaces provide people with skills that can translate into successful careers. Some makers go on to become entrepreneurs and start companies.

CHAPTER ONE

MASTERING SKILLS THROUGH MAKING

M akerspaces are busy hives of production and activity. They make learning fun because you are actually constructing something and can see the end results. Students find makerspace programs in their schools, local libraries, colleges, churches, and community centers. In a sense, makerspaces are an evolution from the electric shops, wood shops, and automotive classes that more high schools once offered.

Sometimes, makerspaces are set up by nonprofit organizations or funded by private industry. At Familab in Longwood, Floridanot far from Disney Worldyoung people are busy soldering and building circuitry. Sector67 in Madison, Wisconsin has students constructing their own flashlights and voice-activated LED lighting. Using programming, welding, and all sorts of electronics, the kids at Vocademy in Riverside, California, whip up all manner of robots. For careers in machine maintenance, you have

to understand the nuts and bolts of how things work, and thats exactly what these makerspaces do.

Like many makerspaces across the country, the Mt. Elliott Makerspace in Detroit gives children and teens the tools, guidance, and space to make things with their own two hands.

If you cant find a makerspace near you, you can always try to set up one on your own. Makerspaces.com and other websites provide many tips. A student may first want to inquire with their school administration to see what might be possible. A basic space will be equipped with electrical outlets, big empty tables where students can work, and a place to store tools and supplies. (First aid kits should always be on the premises as well!)

TOOLS AND TEACHERS

Markerspaces need to offer a variety of tools. Some are very simple and more craft-oriented with just scissors, glue, cardboard, and various art supplies. The ones that give skills for machine maintenance will have more advanced items. These may include batteries, copper foil tape (for learning about circuitry), LED lights, and circuits.

Many of these spaces, like the Artisans Asylum, in Somerville, Massachusetts, are dedicated to fabrication, which is the act and process of manufacturing or inventing something. You could call it making something from scratch. Metal fabrication is the construction of metal items by means of cutting, bending, and assembling, and its often taught at makerspaces. Because machines and their parts are almost always made of metal, future maintenance techs and engineers can benefit from these programs.

A key ingredient for any makerspace is usually experienced staff, who can teach how to use all the tools to build the items. While experts are great to teach others, John Spencer, who has written a few articles on makerspaces, said on Medium.com that teachers dont have to know how to do everything in the makerspace. They can learn as they go along with the students, and they dont necessarily need the latest cutting edge equipment. Spencer joined forces with a teacher and together they learned Linux, hacked old computers, and got them working again. This was knowledge they could now share with students. As Spencer points out, limitations can be opportunities to innovate.