Published in 2020 by The Rosen Publishing Group, Inc.

Copyright 2020 by The Rosen Publishing Group, Inc.

All rights reserved. No part of this book may be reproduced in any form without permission in writing from the publisher, except by a reviewer.

Names: Kamberg, Mary-Lane, 1948 author.

Title: Careers in welding / Mary-Lane Kamberg.

Description: First edition. | New York: Rosen Publishing, 2020. |

Series: Makerspace careers | Audience: 712 | Includes bibliographical references and index.

Identifiers: LCCN 2018052182| ISBN 9781508188162 (library bound) | ISBN 9781508188155 (pbk.)

Subjects: LCSH: WeldingVocational guidanceJuvenile literature. Classification: LCC TS227.7 .K36 2020 | DDC 671.5/2023dc23

INTRODUCTION

S ince ancient times, humans have been working to join metal pieces together for parts, products, construction, maintenance, and repair. In modern times, more than one hundred processes accomplish that goal by welding a wide variety of metals for a myriad of purposes. Along with welding, workers join metals using the related techniques of soldering and brazing. The wanted end product, types of metals used, and where the job will be performed contrib- ute to the choice of method.

Because of Americas trend toward new manufacturing and construction, as well as the need to improve infrastructure, including bridges, the job outlook for welders is good. In fact, because of the increased need for these skilled workers, along with the fact that many welders are reaching retirement age, experts agree that there is a shortage of qualified workers in the field.

Thats why unions, trade schools, and others are recruiting more welder trainees. Recruiters are increasingly appealing to youth and women to fill the gap. Female welders filled shipyards and construction sites during World War II, when the vast majority of able-bodied men were busy fighting overseas. However, men dominate the ranks of todays welders.

Public access workshops known as makerspaces, Fab Labs, or hackerspaces are great places to learn the skills necessary to be admitted to apprenticeship programs. These venues offer access to tools, machines, and other equipment, as well as space to work on individual projects. Some makerspaces offer classes, as well as advice from other participants in a friendly, sharing environment.

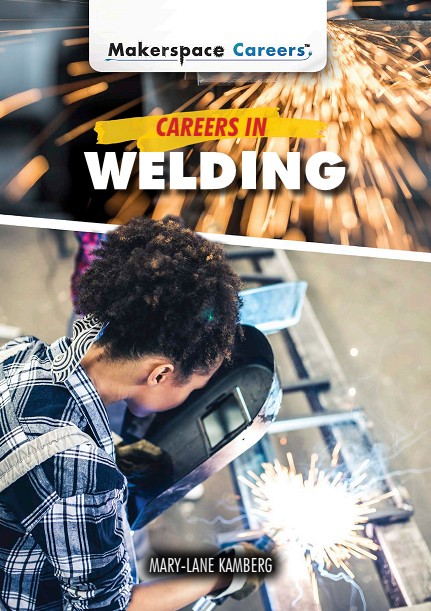

Although welding has traditionally been a predominantly male career, more women are training to become welders. This is a welcome change since many qualified welders are reaching retirement age.

The good news is that makerspaces are open to teens, who can start preparing for welding careers. High school technical education classes cover the basics. So young people can try their hands at welding to see if they like it and have an aptitude for it. Self-teaching opportunities include online videos and online classes.

For further instruction, potential welders can take classes at community colleges, private vocational schools, and union training centers to prepare for apprenticeship programs.

Practice is the best way to prepare for a welding career. And makerspaces can be used for that purpose, too. The goal is to be able to make the same types of welds over and over and have each look the same. That takes commitment and persistence over time.

Welders must be lifelong learners. New techniques, tools, and machinery constantly appear in the industry. So even trained welders need continuing education to stay up to date. Other tips for a successful career include supplementing training with additional certifications for different types of welds and specializing in a particular weld.

In this book, youll learn what welding careers are like, as well as how to get started in the field, where to get additional experience, and how to find welding jobs. Youll also learn tips for presenting yourself in the best light on rsums and during in-person job interviews. Youll also get job outlook and other information from the Bureau of Labor Statistics.

CHAPTER ONE

WHAT IS WELDING?

A aron McNeely likes to talk about his welding career as a boilermaker. I do things people cant comprehend, said the welder from Clinton, Missouri. Theyre shocked when I tell them about my job.

He wows friends with tales of the times he performed incredible feats in his welding jobs, including one in which he worked inside a metal box where the temperature was 160 degrees Fahrenheit (71 degrees Celsius). He impresses them with the story of the time he worked at a nuclear power plant surrounded by guards with assault rifles. He tells them about a fellow welder who had to work on a power plant smokestack 707 feet (215 meters) in the air.

As a boilermaker, you have to be able to stand on your head and make an X-ray quality weld using a mirror, he said in an interview. An X-ray quality weld is one that passes examination using an X-ray machine to see beneath the surface.

Although some welders work in machine shops, others work in the field, either indoors or outdoors in a variety of environments and weather conditions.

Welding is the process of using heat to join or cut pieces of the same metal. A blowtorch fires up. Sparks fly. A sizzling sound fills the air. And the temperature rises as welders shape metals into useful products. Not all welds use blowtorches. And some types of blowtorches create no sparks at all. But the image of workers wearing welding hoods as sparks fill the work space is what many picture when they think of welders.

Welding is an important skill that is in demand in construction, manufacturing, and other industries. Welders build ships, tankers, submarines, aircraft, cars, and locomotives. They also build and repair power plants, forge tools, and manufacture consumer goods. The US Department of Labor predicts employment in the field will increase 6 percent between 2016 and 2026, about the same as the average estimated growth for all jobs.

McNeely had no intention of pursuing a welding career. In college, he thought hed like to be a teacher. He took up welding as part of his hobby driving in a demolition derby. Demolition derby is a motor sport in which drivers compete by purposely crashing their cars into each other. McNeely had his own welding machine and learned to use it to repair his demolition cars at home.

I started college, but couldnt afford to continue, he said. But I needed to make a decent living. A welding shop gave me a job even though I wasnt experienced. I took a welding test, and they saw potential.

Later, when he had more experience, he wanted to work in the field on job sites rather than in a shop. He attended a welding school in Tulsa, Oklahoma, and wanted to apply for an apprenticeship with the pipefitters union. An apprenticeship is a paid or unpaid supervised training period in which participants learn a trade. However, he learned that it would take six years. Instead, he applied to the International Brotherhood of Boilermakers, Iron Ship Builders, Blacksmiths, Forgers, and Helpers, one of the labor unions that represent welders. That union accepted him into its four-year program.