Galvery - Basic Welding for Farm and Ranch: Techniques and Projects for Fixing, Repairing, and Fabricating Essential Tools and Equipment

Here you can read online Galvery - Basic Welding for Farm and Ranch: Techniques and Projects for Fixing, Repairing, and Fabricating Essential Tools and Equipment full text of the book (entire story) in english for free. Download pdf and epub, get meaning, cover and reviews about this ebook. year: 2019, publisher: Storey Publishing, LLC, genre: Home and family. Description of the work, (preface) as well as reviews are available. Best literature library LitArk.com created for fans of good reading and offers a wide selection of genres:

Romance novel

Science fiction

Adventure

Detective

Science

History

Home and family

Prose

Art

Politics

Computer

Non-fiction

Religion

Business

Children

Humor

Choose a favorite category and find really read worthwhile books. Enjoy immersion in the world of imagination, feel the emotions of the characters or learn something new for yourself, make an fascinating discovery.

- Book:Basic Welding for Farm and Ranch: Techniques and Projects for Fixing, Repairing, and Fabricating Essential Tools and Equipment

- Author:

- Publisher:Storey Publishing, LLC

- Genre:

- Year:2019

- Rating:3 / 5

- Favourites:Add to favourites

- Your mark:

Basic Welding for Farm and Ranch: Techniques and Projects for Fixing, Repairing, and Fabricating Essential Tools and Equipment: summary, description and annotation

We offer to read an annotation, description, summary or preface (depends on what the author of the book "Basic Welding for Farm and Ranch: Techniques and Projects for Fixing, Repairing, and Fabricating Essential Tools and Equipment" wrote himself). If you haven't found the necessary information about the book — write in the comments, we will try to find it.

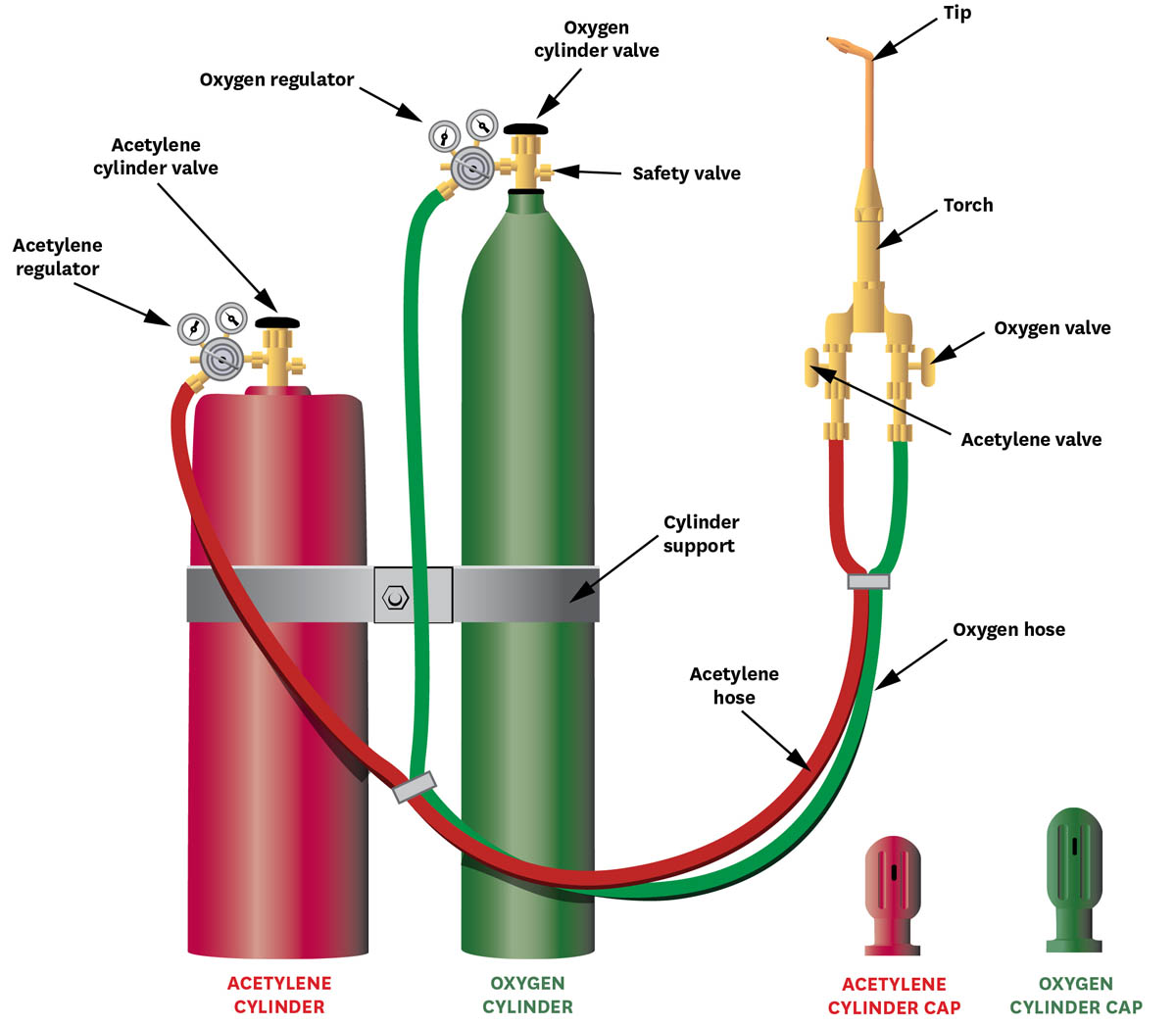

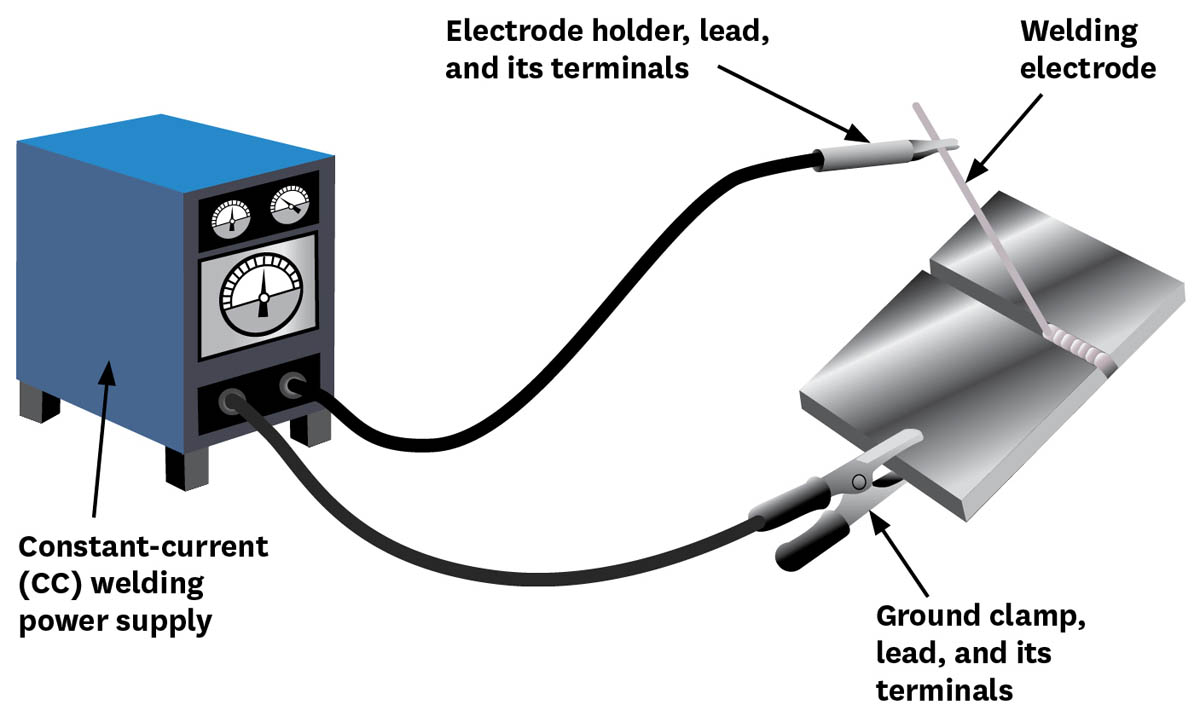

Farmers, ranchers, and homesteaders who know how to weld can repair and even fabricate some equipment on their own, saving both time and money. Basic Welding for Farm and Ranch introduces this crucial skill and covers the most popular techniques used by the home hobbyist and DIY devotee, with chapters and detailed illustrations dedicated to oxyacetylene welding (or gas welding), stick welding, MIG, and arc welding, as well as brazing and soldering. Along with guidance on equipment selection and use, and safety precautions, this book offers 12 projects and repairs commonly faced on the small farm or homestead, with step-by-step photography guiding readers through building a wall-mount hay feeder, repairing a garden rake, making horseshoe hooks, and more.

This publication conforms to the EPUB Accessibility specification at WCAG 2.0 Level AA.

Galvery: author's other books

Who wrote Basic Welding for Farm and Ranch: Techniques and Projects for Fixing, Repairing, and Fabricating Essential Tools and Equipment? Find out the surname, the name of the author of the book and a list of all author's works by series.