WELDING

COMPLETE

TECHNIQUES, PROJECT PLANS & INSTRUCTIONS

Copyright 2009

Creative Publishing international, Inc.

400 First Avenue North, Suite 300

Minneapolis, MN 55401

1-800-328-0590

www.creativepub.com

All rights reserved

Library of Congress Cataloging-in-Publication Data

Welding complete : techniques, project plans & instructions.

p. cm.

Includes index.

Summary: Explores the practical and decorative aspects of

welding, including information on tools, materials, safety and

dozens of metalwork projects Provided by publisher.

ISBN-13: 978-1-58923-455-0 (soft cover)

ISBN-10: 1-58923-455-3 (soft cover)

Digital edition: 978-1-58923-455-0

1. Welding. 2. Welding Equipment and supplies. I. Creative

Publishing International. II. Title.

TT211.W45 2009

739'.14 dc22

2009010736

President/CEO: Ken Fund

VP for Sales & Marketing: Kevin Hamric

Home Improvement Group

Publisher: Bryan Trandem

Managing Editor: Tracy Stanley

Senior Editor: Mark Johanson

Editor: Jennifer Gehlhar

Senior Design Managers: Jon Simpson, Brad Springer

Design Manager: James Kegley

Technical Review: Kris Kersten

Page Layout Artist: Rick Penn-Kraus

Lead Photographer: Joel Schnell

Photo Coordinator: Cesar Fernandez Rodriguez

Photo Set Builder: Bryan McLain

Shop Help: Scott LaSalle, Max LaSalle

Production Managers: Laura Hokkanen, Linda Halls

Additional Contributors

Todd Bridigum, Carl Peters, Jenny Ogborn, Bruce Reed at SIC.

Cover photograph: Fotosearch Stock Photography; inset images CPi

CONTENTS

Jointing

Introduction

Welding is a practical skill that is also great fun. The number of welded items in our everyday lives is practically uncountablethe spot welds on our cars and tractors, the welded railing on our front steps, the superstructure of the buildings in which we work, and the bridges over which we drive. Welding also makes everyday yard and interior items possible, like patio trellises, wine racks, tables, and shelves.

This book thoroughly discusses welding basics and techniques such as safety, setting up shop, tools, metals, and welding types. Once you have covered the basics, you can move on to the specific projects in this bookcomplete with how-to instructions, tools and materials lists, and illustrated plansto develop your welding skills. At the same time, youll benefit from a wide range of new furnishings in and around your home.

The home dcor section includes instructions for practical and useful items commonly used in homes, such as mirrors, coat hooks, tables, and shelves, as well as decorative items like the iron cross and fireplace candelabrum.

The outdoor chapter includes heavy-duty projects suitable for hardworking DIYers, including a yard trailer and truck rack. There are also common exterior home improvement projects such as the stair railing, arbor, gate, and firepit.

Notice To Readers

Welding is a dangerous activity. Failure to follow safety procedures may result in serious injury or death. This book provides useful instruction, but we cannot anticipate all of your working conditions or the characteristics of your materials and tools. For safety, you should use caution, care, and good judgment when following the procedures described in this book. Consider your own skill level and the instructions and safety precautions associated with the various tools and materials shown. The publisher cannot assume responsibility for any damage to property or injury to persons as a result of misuse of the information provided.

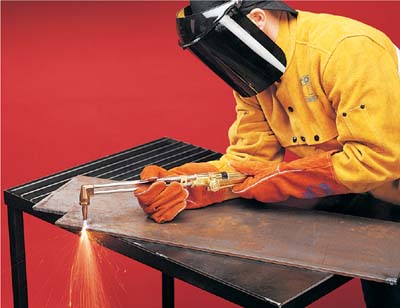

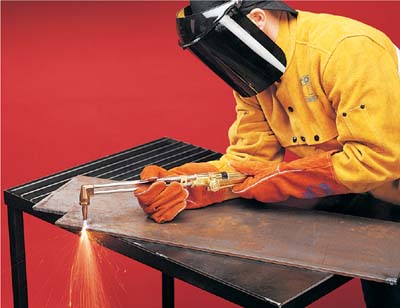

Welding is all about heat, about using heat to melt separate pieces of metal so they will flow together and fuse to form a single seamless piece. Regardless of the welding or cutting process, your ability to control the heat generated by the flame or arc determines the quality of your welds and cuts.

Certain terms are used to describe the heat and action of all the welding processes. The parts being welded together are referred to as the base metal. Additional metal, called filler, is often added to the weld. The molten puddle is the area of melted base metal and filler metal that you maintain as you create your weld. To have fusion of metals, the base metal and filler metals must have the same composition. Methods for joining metal without fusion are called soldering, brazing, and braze welding. These methods can be used to join similar or dissimilar metals.

Oxyacetylene welding and cutting use flames to generate the heat to melt the metal. Shielded metal arc, gas metal arc, gas tungsten arc welding, and plasma cutting use an electric arc for heat generation. With oxyacetylene welding, you have time to watch the puddle develop as the metal turns red, then glossy and wet looking, then finally melts. With the arc processes, the puddle forms quickly and may be difficult to see because of the intensity of the arc. It is important to have ample lighting and clear vision so you can watch the puddle and move it steadily.

Penetration of the weld is also a critical heat-dependent factor. A strong weld penetrates all the way through the base metal. Matching filler material size and heat input to the thickness of the base metal is important. It is easy to get a good-looking weld that has not penetrated the base metal at all and merely sits on the surface. At the opposite end of the spectrum from a cold, nonpenetrating weld is burn throughwhere the base metal has gotten too hot and is entirely burned away, leaving a hole in the base metal and the weld.

Heat distortion is a byproduct of all welding and cutting processes. It is obvious that applying a flame to metal in the oxyacetylene process makes the metal hotand the electrical arcs are actually four to five thousand degrees hotter than the oxyacetylene flame. When metal is heated, it expands; when it cools, it contracts. If not taken into consideration, this expansion and contraction may cause parts to move out of alignment. This is why tack welding and clamping project pieces is critical to successful welding. It is also important to match the welding process to the base metal thickness. For example, shielded metal arc welding is generally not used on materials less than / thick. The process is too hot and too difficult to control on thin material. On the other hand, gas metal arc welding works well on very thin sheet metal, if you are able to adjust the machine to a low enough voltage.

Oxyacetylene welding