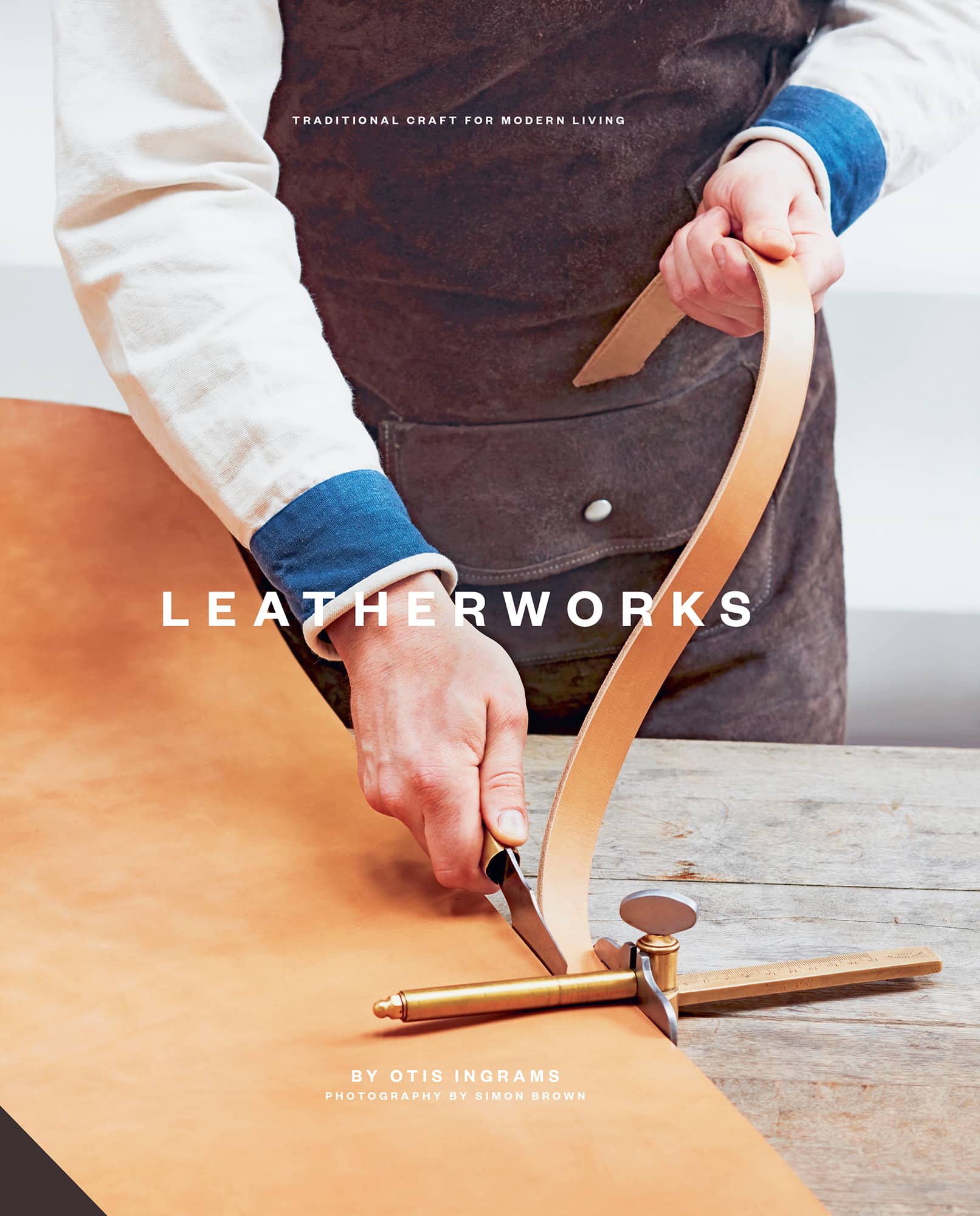

LEATHERWORKS

TRADITIONAL CRAFT FOR MODERN LIVING

BY OTIS INGRAMS

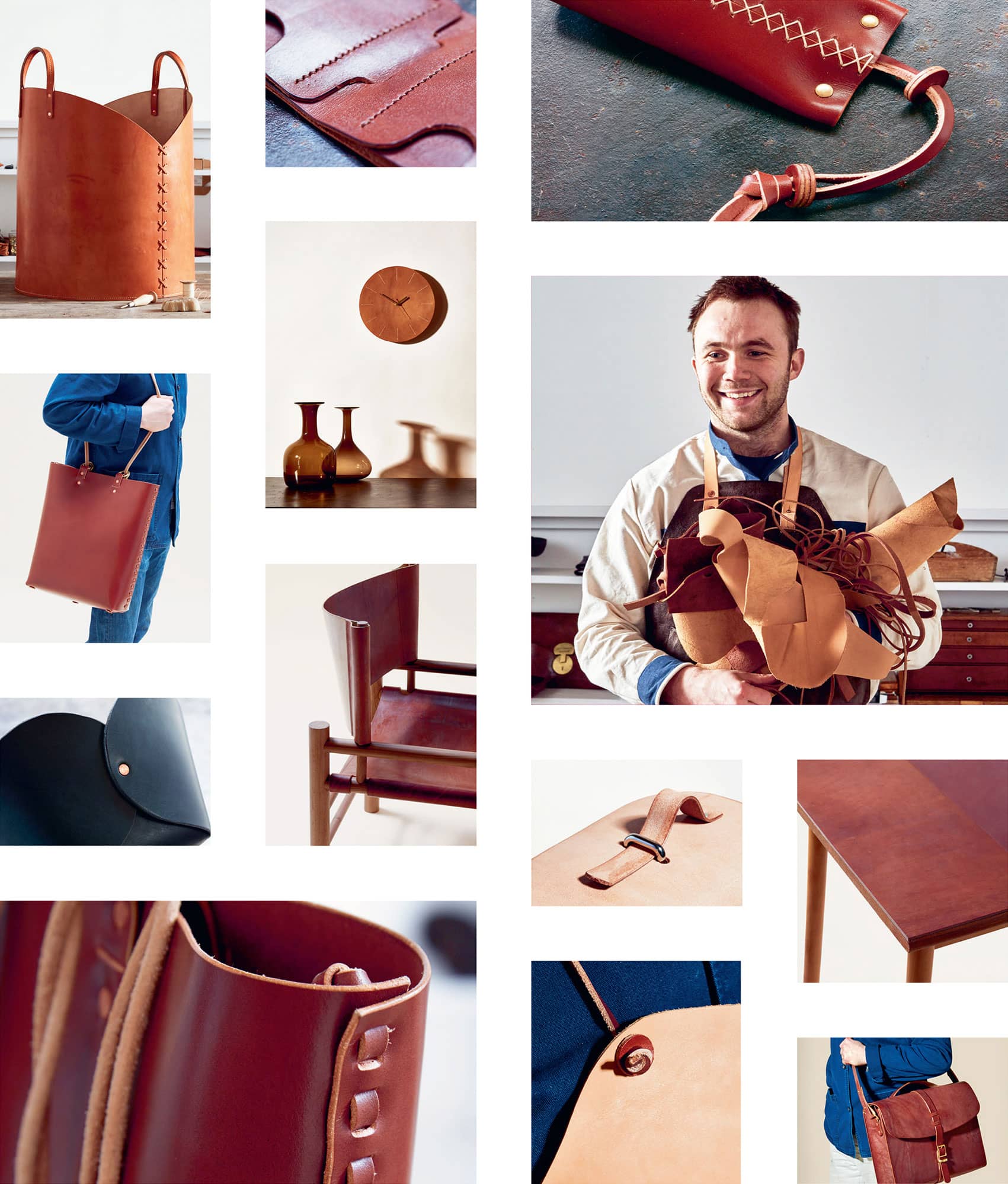

Why I work with leather

I fell into leatherwork, fell in love with it and never looked back. It is not a career that I set out to have, nor had it ever been on my radar. Then I made my first piece. Within a few months I knew that I wanted to pursue the craft indefinitely.

One of the great appeals of the craft is the ease of the initiation process. With no sawdust or filings to clear up, it is predominantly a tidy craft and one that can be practised in small spaces and domestic settings. I have worked in my kitchen, in barns, on shop floors and even in hotel rooms. Most of the tools used for leatherwork are hand-held and therefore small in size. They are often beautiful in form, and are satisfying to use and eventually master. When I first started, I quickly saw a progression in skill with practice, and continue to notice improvement today. The equipment and leather are easily portable, making it possible to work anywhere, something very few crafts offer. Due to the sheer variety of tools that accompany each area of leatherwork, I never get bored. There are always new techniques to discover, practise and improve on. The leatherworking community is very active and generous with their knowledge sharing techniques and documenting their work. I have learned a huge amount from my online contemporaries around the world.

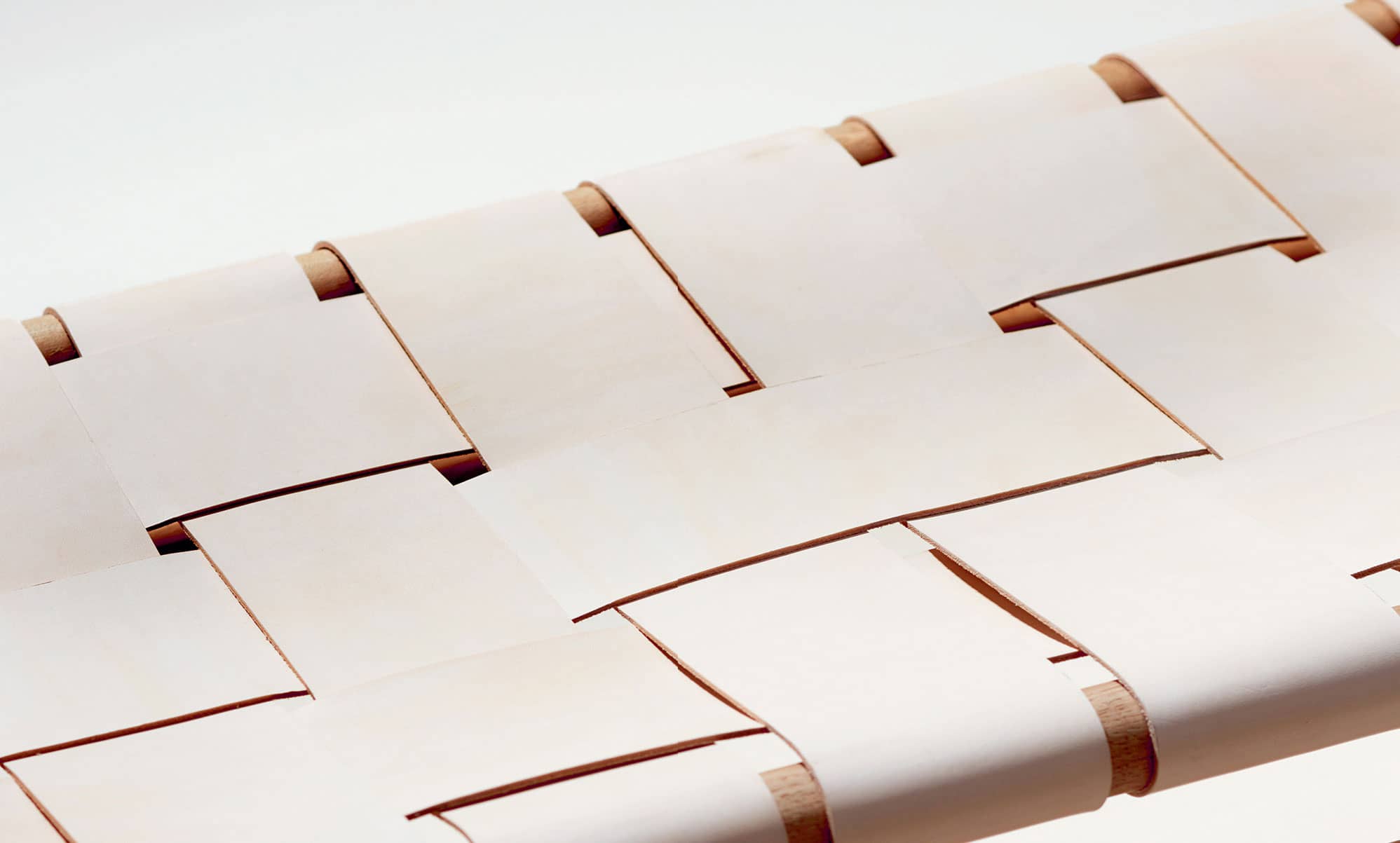

The primary reason I started working with leather was, of course, the material itself. Leather alongside others such as wood, stone, iron or bronze, reed and wool is a very primal material. It feels natural to work with, and it is impossible not to feel connected to it through its organic origin. The intrinsic beauty of the material is something that always impresses me, and tanneries today produce a breathtaking array of finishes and colours for hides and skins of all kinds. Leather can be very thick and structurally rigid, or buttery soft, thin and pliable. Leather can be used to make a vast array of items, or it can be incorporated into items made of other things. It is this capacity and promise within the material that makes leatherwork so exciting and worthwhile. The variety of projects I demonstrate in this book hopefully reflects this potential.

And another wonderful aspect of the craft is the huge variety of tools. Each one has its own historical background and cultural significance, and provides a reflection of the historical reality within which they were formed. They have their own purpose, and their own governing principles and sensibilities. In turn, each contains its own techniques and carries its own unique aesthetic. I have incorporated many of these within the projects.

Types of leather

There are few materials or organic substances derived from nature that offer such a vast array of potential as leather. In the same way as the grape produces an almost infinite variety of wines, or as milk when processed turns into butter, cream or cheese of varying finish and flavour, by tweaking the tanning process in the journey from animal skin to leather, the tanner creates an endless variety of substance, structure, texture and finish. Now more than ever, with contemporary technologies, the leather industry around the world is creating a dizzying assortment of leather for all sorts of purposes from traditional bridle leather used for case-making and equestrian equipment to soft and supple upholstery hides used in the manufacture of furniture and automobiles. The dazzling colours and finishes on offer provide the leatherworker with more opportunity in crafting and designing than ever.

I have always preferred the traditionally produced vegetable-tanned leathers; this natural process involves bark from oak, chestnut, birch and mimosa trees, along with other plant extracts. A liquor is created from these vegetative materials in which skins are steeped for a lengthy period of time up to 12 months in some cases. The tannins are astringent and penetrate the fibres to take out the moisture, resulting in a stronger leather. Tanners use various types of tannins to create different types of leather, and with subtle variations in the recipe, different leathers can be produced. Leathers are finished in a process called currying, whereby the hides are rubbed with dyes, oils, waxes and fats to increase suppleness in the leather, to make it more usable. The amount of each finishing substance used also determines the type of leather it will become. Chrome tanning involves chemicals rather than natural substances, and is a much quicker process. Latigo leather is produced with a combination of both vegetable and chrome tanning. All the leathers used in this book are vegetable tanned.

Most leatherworking uses bovine leather for its strength, sheer size and versatility across a range of uses. You refer to cow hides and sheep, pig or goat skins. The cow hide is usually split into three cuts or sections: shoulders, butts and bends, and sides. A shoulder has more grain marks across it and comes in a more or less square panel. It is usually thick yet flexible, and is a great all-round cut to use. Butts are the strongest part of the animal and have a tight compact grain. Comprising the whole of the back below the shoulder, they are used for belts, straps and saddlery: work where durability and strength are needed. A bend is half a butt and is used more often than a whole butt, as it is more manageable to work with. Sides comprise a bend plus half a shoulder and run the length of the cow, as the name suggests.

Getting started with tools

One of the great attractions of leatherworking is the tools. The variety is huge and each one has a very distinctive purpose it can be quite overwhelming when faced with the full gamut. The emblem of the leatherworker or saddler is the iconic round knife with its broad sweeping arc of a blade. Similarly, the uniqueness of these tools, such as the pricking iron, gives them a great character. They are designed to perform a single function as well as possible. It is easy to spend a huge amount of money on tools, simply due to the sheer number of them.

The quality of these tools also varies wildly and the higher-end hand tools from companies such as Vergez Blanchard and CS Osborne cost a lot due to the work put into them. These are heirloom-quality pieces, however, and for any enthusiast they are well worth the extra money. Many of the old tool factories have closed, but their tools float around on the internet. Look out for names such as Dixon, Blanchard, Barnsley or Gomph. In recent years there has been a proliferation of cheap tools from the Far East that fulfil the basic requirements when you start out on projects they are certainly far cheaper, but dont expect them to last forever. A first set of pricking irons can be purchased cheaply online, but do bear in mind that they can snap quite easily, and if you are looking to pursue leatherworking, then you should invest in good-quality ones. Similarly with knives. Make sure you buy one with a good-quality steel blade and a good sharpening stone. With a bit of research online you can find some. I have built a collection of antique tools of very high quality. They are often cheaper than a new equivalent.