Chapter 4

Tractors and Tractor Implements

Long ago, mechanization revolutionized agriculture. Today, its hard to get by without it. You can garden with a shovel, a fork, a rake, and a few other simple tools, but to farm anything larger than a small plot, you need more than this.

Tractors and the equipment they operate are designed to do a multitude of tasks. Both come in a dizzying array of shapes, sizes, and models. The subject is so vast it could fill the pages of many a hefty tome. Some folks are great tractor and farm machinery buffs. Not me, Im afraid. Having never excelled in the mechanical domain, the broad subject of farm equipment is not my strong suit. This personal deficiency puts me at a disadvantage when interacting with farmers and others who are well versed on these manly matters. Fortunately, though, Ive pieced together enough knowledge to get by, and my ability to run a small farm does not seem to have suffered greatly.

Without a doubt, I am heavily reliant on the three tractors I own and the several implements they operate. Over the years, Ive gained a fair understanding of what they can and cannot do. Ive taught myself to look after each of them to the best of my ability. Ive become reasonably competent with a grease gun, an oil filter wrench, and a few other basic maintenance tools. Ive learned to be on the lookout for telltale signs (and sounds) that a tractor or piece of equipment needs attention. Ive developed good relations with neighboring farmers and mechanics who are willing to share their knowledge with me and tackle repairs when necessary. Their support is vital. If an important piece of equipment fails be it the water-wheel transplanter, the manure spreader, or the truck that goes to market I want it back in running order as quickly as possible.

Ive grown wary of being totally dependent on one tractor or one piece of equipment to perform an important, time-sensitive task, knowing that sooner or later, Murphys Law will take hold. The best defense against Murphy, Ive learned, is having a backup plan and some built-in redundancy in other words, more than one way to achieve the same end, and more than one piece of equipment to get me there.

Its been a bit of a struggle, but the truth is, despite my mechanical limitations, Ive grown surprisingly fond of my tractors and other farm machinery. When well maintained and accorded proper respect, they do the heavy work that is asked of them year after year. If they were taken away, Id sorely miss them, and more to the point, Id have to give up farming for a living.

Start with a Tractor

To the uninitiated, a tractor might appear to be not much more than a slow-moving vehicle with large rear tires and good traction. Indeed, by itself, theres not a whole lot you can do with such a machine. Its only when you pair your tractor with an appropriately sized farm implement that its utility becomes evident. Expand the range of implements, and a whole world of possibilities opens up.

Tractor Essentials

There are four basic features that make modern tractors (i.e., those manufactured since the mid-1900s) so useful; however, be sure that any tractor you buy, however old, has all of them, in working order. These four features are:

- Draw bar

- Hydraulic hose lines

- Three-point hitch

- Power take-off shaft

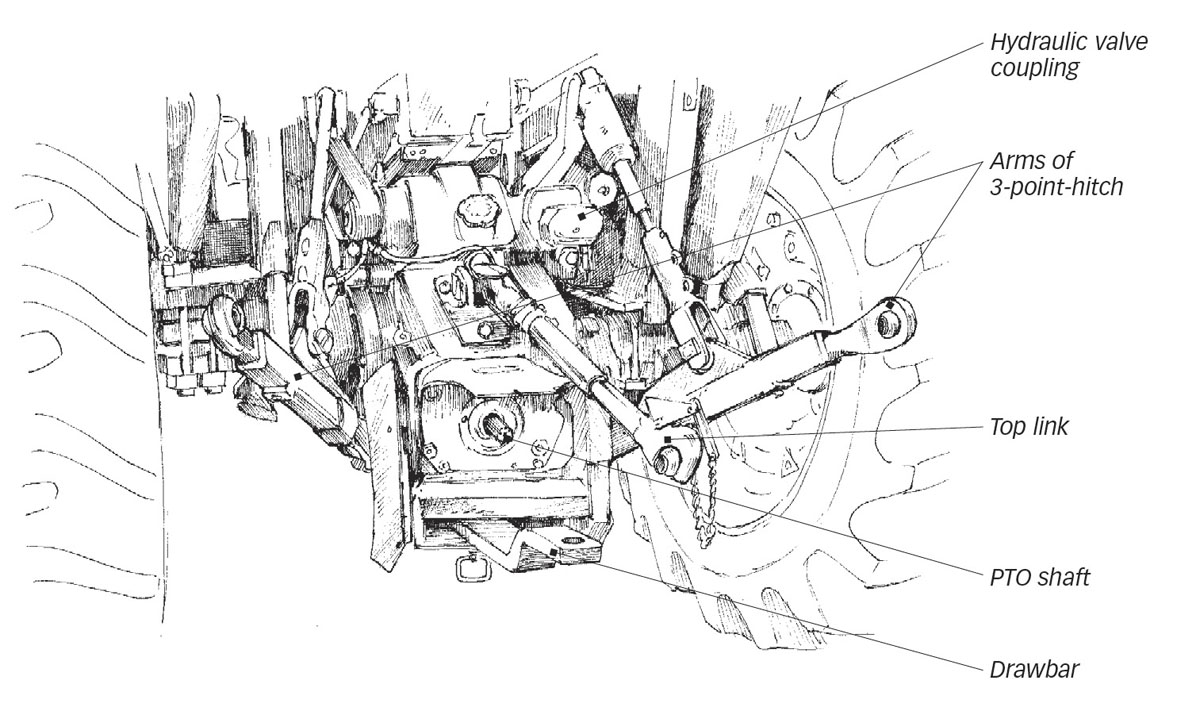

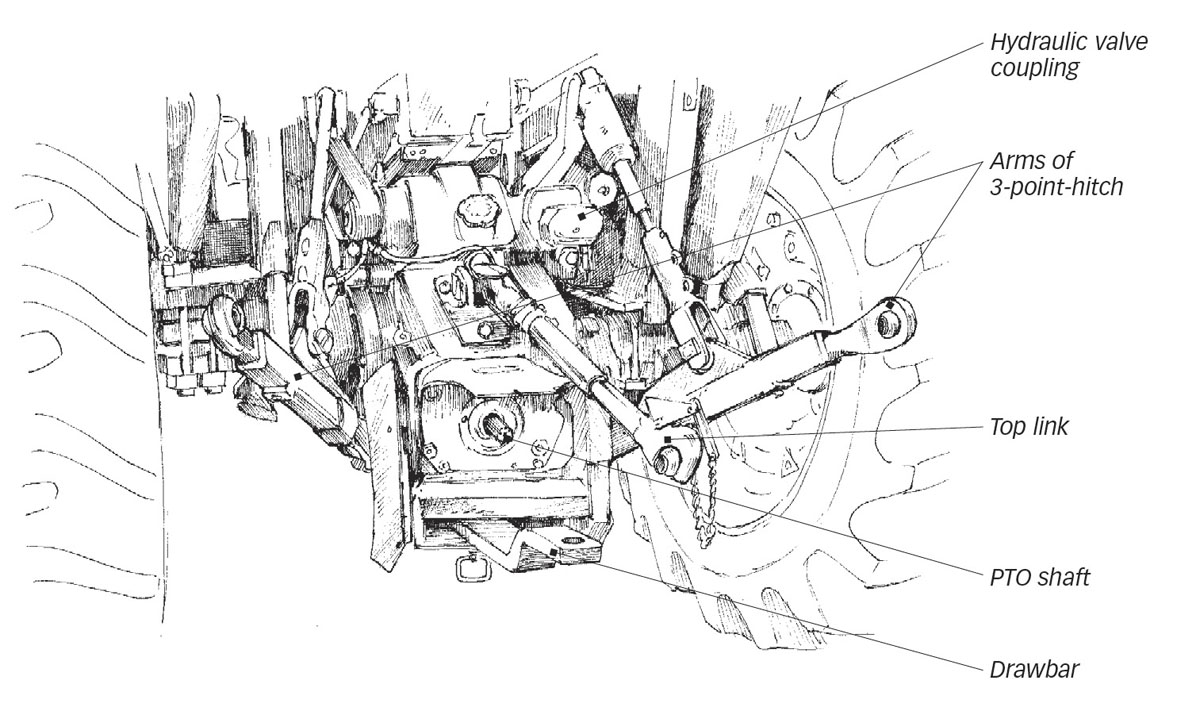

Draw Bar

The draw bar is a simple heavy-duty tow bar that enables you to pull objects with wheels, such as carts and wagons. It will also allow you to pull drag implements that dont have wheels, such as discs, harrows, and some old cultivators. Usually, its just a matter of lining up the tow bar with the implement you want to pull and conjoining the two with a hitch pin. Almost all tractors have draw bars.

Hydraulic Valve Coupling

A remote hydraulic valve allows you to lift any drag implement that has a hydraulic cylinder and is attached to the tractors draw bar, so you can transport it to the field without tearing up your driveway or lawn. Once you get to the field, you release the hydraulic pressure, which allows the implement to drop into position, whereupon you can go to work. Hydraulic couplings and hose lines can be used to do other things as well, such as open and close the gate of a manure spreader or adjust the position of an implement while on a slope. Make sure that any tractor you buy has at least one remote hydraulic breakaway coupling that will accept a hydraulic hose.

Three-Point Hitch

A tractors three-point hitch comprises two sturdy arms that can be raised and lowered hydraulically and a third point known as a top link. Think of the two arms as the bottom corners of a roughly equilateral triangle and the top link as the central apex. Unlike the two arms, the top link has no hydraulic capability, though it has a telescoping capacity and can be adjusted manually.

Many useful implements are three-point-hitch compatible, meaning you can easily attach them to your tractor, transport them to the field, then lower them to the appropriate working depth. For example, you might want a chisel plow to penetrate 10 or 12 inches into the soil, but a rototiller to go only 4 or 5 inches deep. A brush hog, on the other hand, might be set to mow 6 inches above the soil surface. The three-point hitch lever, which is accessible from the drivers seat, enables you to adjust the implement to the depth that you want.

If youre considering a larger tractor (40 hp or above), make sure that the lower arms of the three-point hitch have a telescoping capability, so you can back up to within a few inches of an implement you wish to attach and use the telescoping arms to make the connection. This feature will make it a lot easier to attach heavy implements.

Power Take-Off Shaft

This splined (or grooved) shaft provides serious rotary power to implements with moving parts, like mowers, rototillers, spaders, and balers. It is usually located in the rear of the tractor and should be treated with great caution. Never make adjustments to a rear-mounted implement while the PTO shaft is engaged and the engine running. It is quite capable of ripping your arm off at the socket. The PTO shaft functions like a second engine on your tractor and can provide power to many different implements. It can even run a stationary piece of equipment such as a log splitter, wood chipper, post-hole digger, or PTO-driven generator.

Rear view of tractor

What Size Tractor?

Tractors and the implements they operate come in a range of different sizes. You want a tractor that suits the scale and nature of your operation. How big it should be will depend on the answers to the following questions.

- How big is your farm?

- How many acres of vegetables are you planning to grow?

- What is the terrain like? Is it level, hilly, undulating?

- What type of soil do you have? Is it a light, well-drained sandy loam or a heavier clay soil? Does it have lots of rocks?

- What implements are you planning to use with your tractor?

- What do you want your standard bed width to be?

- Do you want a four-wheel-drive tractor?

- How mechanized do you wish to be?

After having posed these questions, let me make a few qualifying and very general remarks about each of them. View my remarks as a way of thinking about the question of tractor size, not as ironclad advice. Just about everything I say could be disputed even by me!